Optimized Li-ion Battery Recycling Machine: High Yield & Low Cost

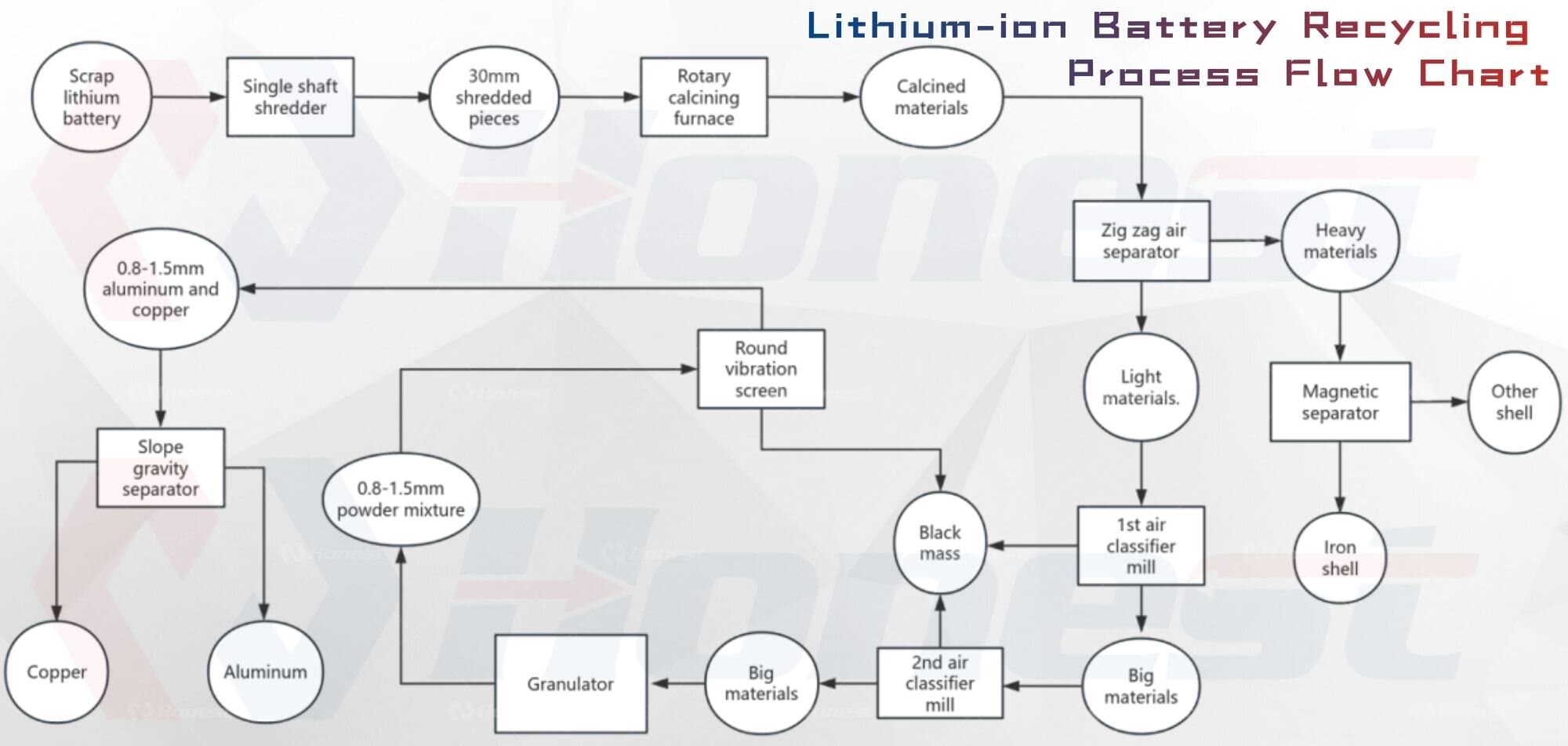

Lithium-battery recycling focuses on recovering valuable materials from the anode, cathode, and separator film. The anode consists of copper foil coated with graphite, the cathode uses aluminum foil coated with lithium cobaltate or nickel-cobalt compounds, and the interlayer is a thin PP separator film. During processing, the active materials are reduced to fine powder (500–600 mesh), known as black mass, while copper and aluminum remain in larger pieces (1–3 mm). This natural size difference enables efficient separation by milling, screening, and air classification.

Our 1000 kg/hour lithium-battery recycling plant integrates shredding, thermal decomposition, mechanical crushing, and advanced physical separation to achieve high-purity recovery of black mass, copper, and aluminum. The single-shaft shredder produces 20–40 mm pieces and offers safer and more efficient performance than double-shaft systems. It operates under nitrogen protection with oxygen below 5%, and a sealed ventilation system continuously removes VOCs. Shredded materials are transferred in a short enclosed path to avoid re-exposure to oxygen.

The rotary calcining furnace performs controlled thermal treatment at around 400°C, breaking down adhesives, releasing electrolytes, and decomposing separator film. Organic fumes are directed to a high-temperature burning chamber, and the exhaust gas is cleaned through a multi-stage purification system including rapid cooling towers, alkaline scrubbers, condensers, and activated-carbon absorption. This ensures compliance with strict environmental standards and suppresses dioxin formation. Induction heating improves energy efficiency by up to 50% compared with natural-gas systems, providing precise temperature control and more stable calcination.

After thermal treatment, materials enter a zig-zag air separator for the first stage of separation, where shell fragments and lightweight residues are removed. The remaining mixture—copper, aluminum, and black mass—moves into a high-speed crushing and powder-selection system. A 3000 rpm air-classifier mill liberates over 80% of black mass in a single pass and achieves significantly higher efficiency than hammer-based crushers. Pneumatic dynamic selection ensures clean separation: copper and aluminum are rejected while black mass is collected with impurity levels typically below 1.5%, and can be reduced to Al <300 ppm when required.

Reconstructed Lithium-ion Battery Recycling Solution

Reconstructed Lithium-ion Battery Recycling Solution

Multiple grinding, air‐classification, and sieving stages refine material size distribution. A round vibrating screen divides the powder into a fine black-mass fraction and a 0.8–1.5 mm mixture. Oversized materials are re-granulated and returned automatically to the milling circuit. Copper and aluminum are finally separated by an automated slope-gravity separator, which delivers high-purity metals while returning mixed fractions to the system for closed-loop reprocessing. Black mass packaging is fully automated and requires only one bag change every 1–1.5 hours.

The complete system requires a space of approximately 55 × 15 × 8 m, with an operating power load of about 378 kW and fuel consumption equivalent to 60 m³/h of natural gas. It can process up to 8000 tons per year, with a black mass recovery rate above 97% and final purity of Al <0.5%, Cu <1%. The combination of controlled shredding, induction-heated calcination, optimized airflow design, precision milling, and gravity sorting ensures stable performance, excellent safety, and maximum material value recovery.

This integrated recycling solution provides a reliable, high-efficiency process for handling scrap lithium batteries, delivering clean black mass and high-purity metals while maintaining strict environmental protection and low operational costs.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Chinese New Year Holiday Schedule and Production Planning Notice

- Why Shredded Paper Is Replacing Plastic Fillers

- Can Copper and Aluminum Be Separated from Mixed PCB Metal Powder?

- What Materials Are Best Processed by a Spiral Shredder

- Solar Panel Frame & Junction Box Removal Machine

- How Cable Granulators Separate Copper from PVC

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export