Equipment Features

Main Applications:Recycling of waste wind turbine blades

Raw Materials:Waste wind turbine blades after cutting.

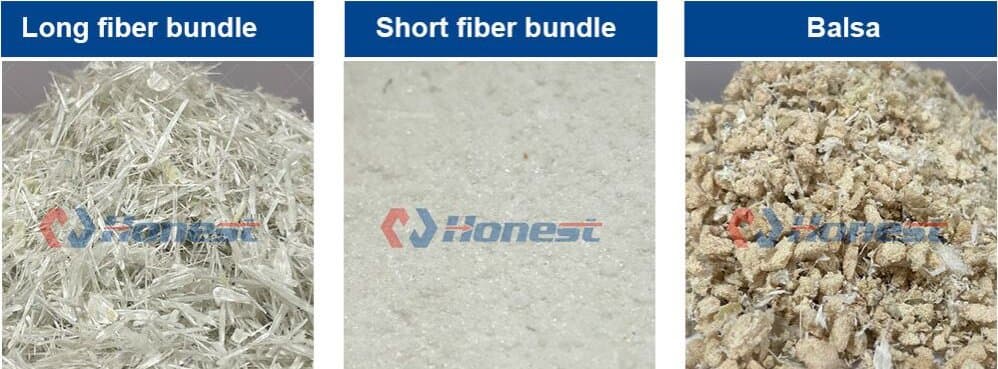

Main Final Products:Long fiber bundle,Short fiber bundle,Balsa

If you want to start your recycling business, feel free to contact us.

Globally, the recycling of composite materials is still underdeveloped, resulting in low recycling rates and many waste blades ending up in landfills. After wind turbines are used for power generation, the discarded turbine blades should also be properly recycled. This wind turbine blade recycling and disposal project aims to reuse or regenerate the materials in discarded blades through the recycling process. The recycling of wind turbine blades faces serious challenges, mainly due to the fact that the materials they are made of, such as glass fibers and carbon fiber reinforced polymers, are difficult to handle.

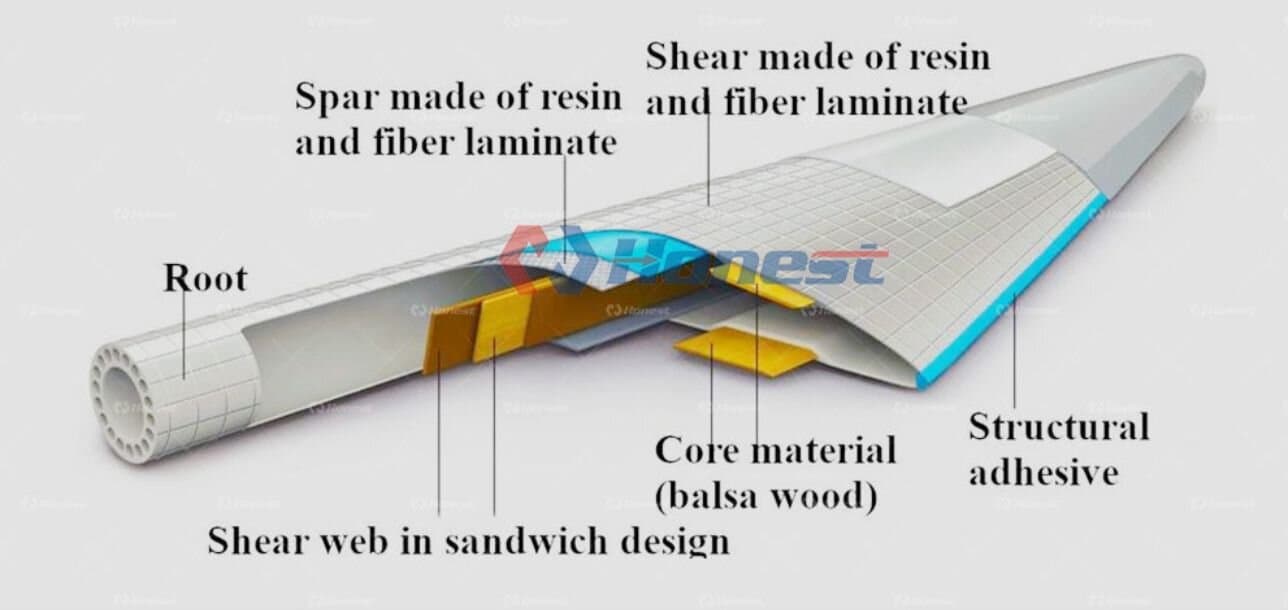

Raw Material

The wind turbine blade, a complex composite structure, features a root for hub connection, a spar of resin and fiber laminate for longitudinal strength, a shear layer of resin and fiber laminate for shear resistance, a lightweight balsa wood core for stability, a sandwich design shear web for enhanced shear performance, and structural adhesive to bond all components, ensuring robust operation under diverse conditions.

To address this issue, we have developed a waste wind turbine blade recycling line that can effectively separate and recycle glass fibers, resins, balsa wood and other materials from wind turbine blades.

Final Products

Through our company recycling techniques, materials such as resin, glass fibers, and others can be separated and reused, minimizing resource waste and reducing environmental impact.

The final products include resin powder, small-sized fiber bundle, large-sized fiber bundles,and balsa wood.This recycling process effectively separates the various materials within the blades, enhancing recycling efficiency.

Technical Parameters

| Model | Power | Size | Capacity |

| HN-201 | 461KW | 40m x 20m x 5m | 1-1.5Ton/H |

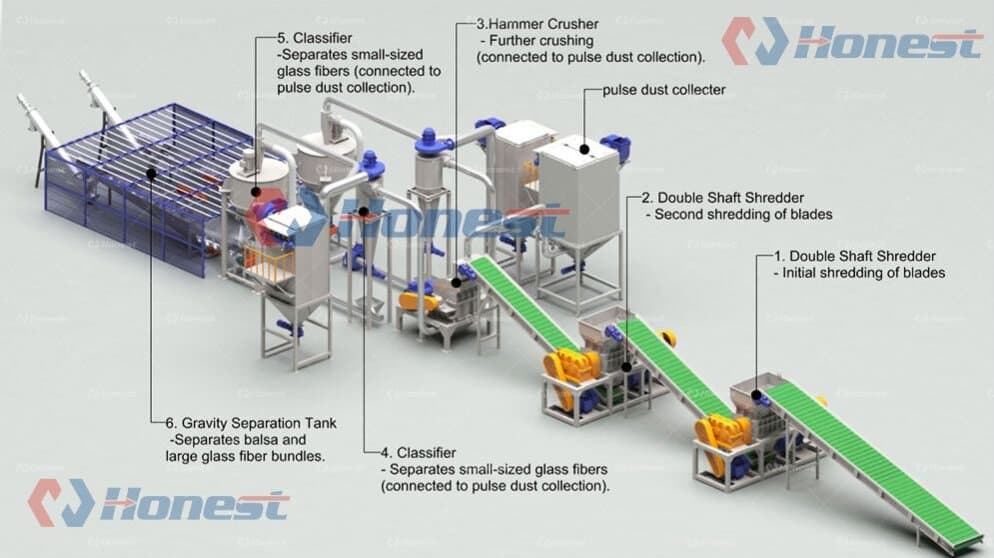

Wind Turbine Blade Recycling Machine Workflow & Brief Introduction

After the wind turbine blades are cut, they enter a recycling line where the material undergoes three stages of crushing and three different separation processes. The end products include Long fiber bundle, Short fiber bundle, and Balsa.

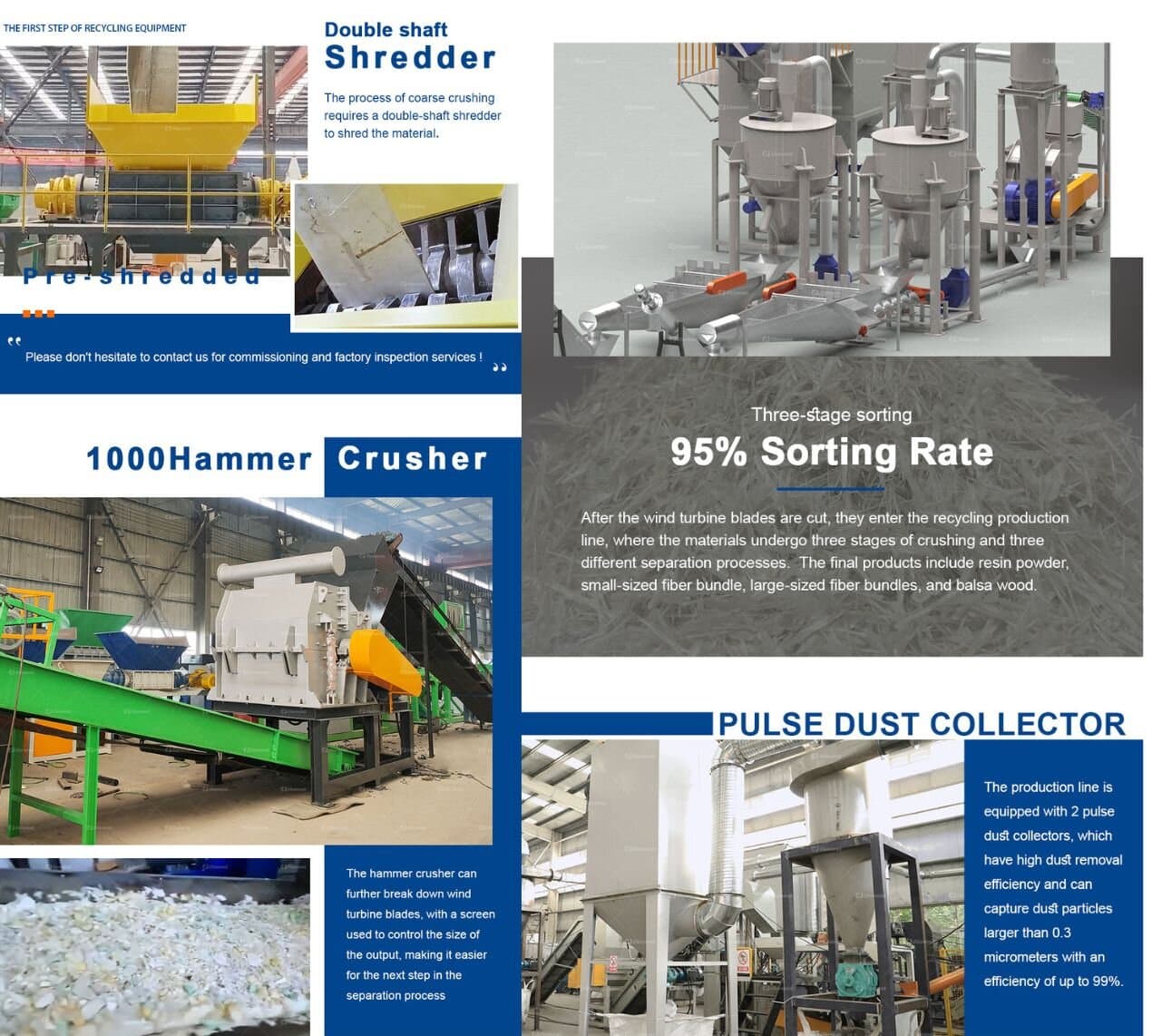

1.Double Shaft Shredder.Initial shredding of blades

2.Double Shaft Shredder Second shredding of blades

3.Hammer Crusher-Further crushing(connected to pulse dust collection).

4.Classifier-Separates small-sized glass fbers(connected to pulse dust collection).

5.Classifier Separates small-sized glass fibers (connected to pulse dust collection).

6. Gravity Separation Tank Separates balsa and large glass fiber bundles

7.pulse dust collecter

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience