Equipment Features

Main Applications:For Waste materials bales

Raw Materials:Tire,Woven bag,Cans,Plastic film,lron drum,Plastic bottle, etc.

Main Final Products:Waste materials into bales

If you want to start your recycling business, feel free to contact us.

Vertical Baler Machine is widely used in many industries, mainly used to compress various waste materials to reduce the volume for easy transportation and storage. Its main application areas include: waste material recycling stations, used to compress various recyclable materials, such as waste paper, plastic, metal, etc.; supermarkets and shopping malls, used to deal with packaging waste such as cartons and plastic films; factories and warehouses, used to compress industrial waste such as scraps and waste products; farms and ranches, used to compress crops such as straw and forage; textile mills and garment factories, used to compress waste cloth, scraps, etc.

Raw Material

The baler machine is mainly used for compressing scrap tires, plastic, clothes, paper, carton, woven bag textile, cotton, cotton wool, linen, clothing, wheat straw, medicinal materials, straw, rice husk, aluminum can and other waste materials into bales.

Final Products

(Above) Waste materials into bales,after compressing, it is easy to transport, so save storage area,transportation cost and labor cost, meanwhile, be beneficial to the environment and waste recycling. Easy operation, durable, long service life, high efficiency, energy saving and low consumption.

Technical Parameters Medium Capacity

| Model | HN-R-150 | HN-R-200 |

| Force | 150T | 200T |

| Bale Size | 1500×1000mm | 1600×1200mm |

| Bale Weight | 850-900KG | 1000-1500KG |

| Efficiency | 4-6Bale/Hour | 4-6Bale/Hour |

| Power(kw) | 18.5KW | 22KW |

| Machine Weight | 5500KG | 8500KG |

| Size(mm) | 2200×1600×3600mm | 2800×2600×3600mm |

Technical Parameters Large Capacity

| Model | HN-R-250 |

| Max Shearing Force | 250 Tons |

| Press Force | 70 Tons |

| Motor Power | 30KW×2 |

| Pump | YCY160×2 |

| voltage (Customized) | 200-680V/3phase |

| Shearing Width | 1400mm |

| Shearing Speed | 3 times/min |

| Max Blade Opening | 500mm |

| Control System | Automatic |

| Loading Box | 1400×5000×700mm |

| Shipping Weight | 25000kg |

| Loading Container | 1×20GP+1×40GP |

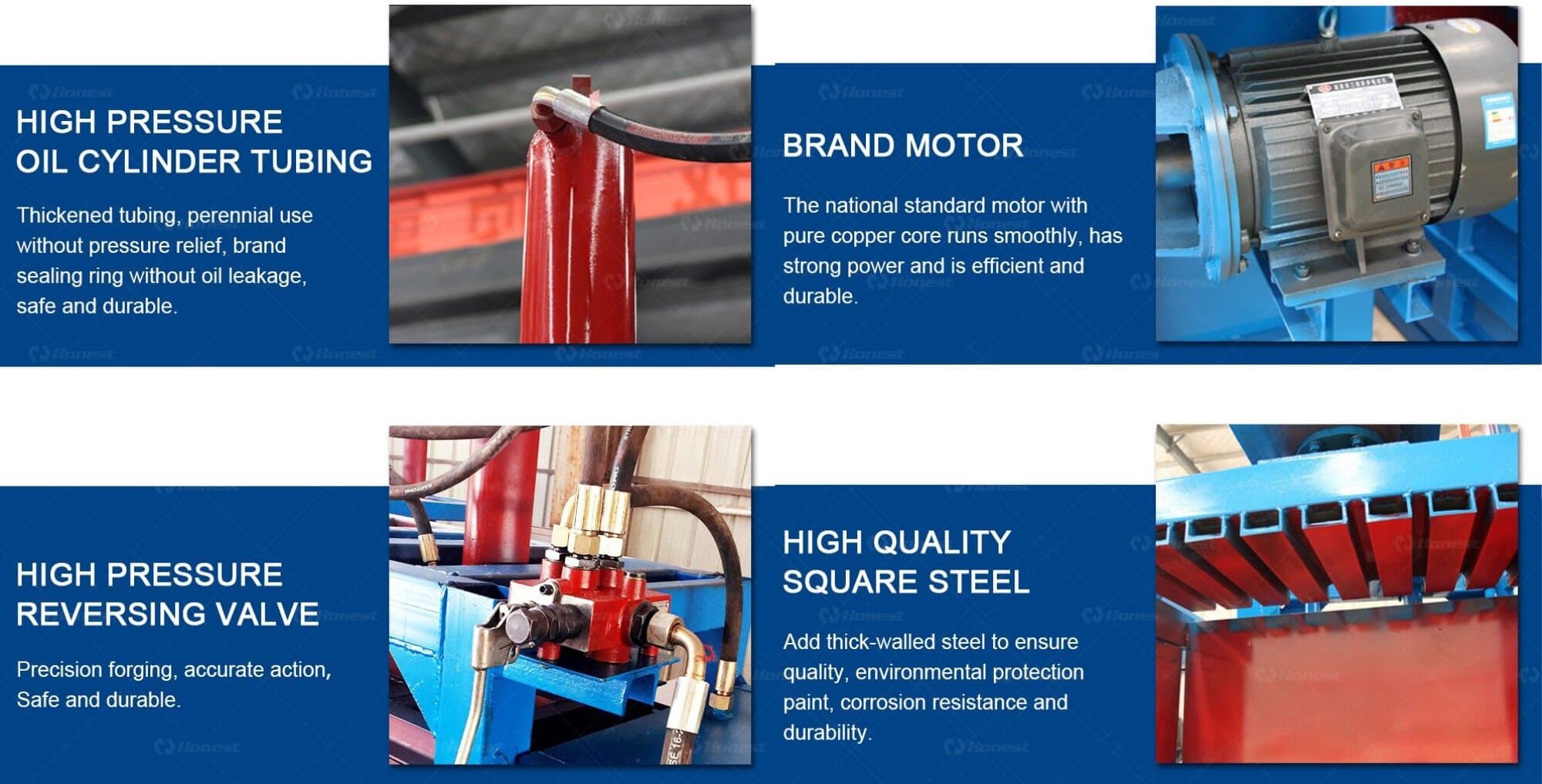

Key components of Vertical Baler Machine

Mainframe system:High-quality thick steel plate with gas-shielded welding casting strong frame.

Conveyor system:High-quality thick I-beam frame, high-strength steel plate conveyor belt.

Hydraulic system:Imported parts are used for key parts such as hydraulic pump, electromagnetic pump and hydraulic cylinder oil seal, which make the packing pressure high, fast, durable and low noise.

Electric control system:Adopt German Schneider Electric, original Mitsubishi PLC programming .controller. Other key accessories such as buttons, sensors, infrared beams, and remote control systems are imported components, which are easy to operate and maintain.

Security alarm system:The program controls the five-channel safety and automatically locks the shutdown alarm. In the case of equipment misoperation, power supply lack of phase, power supply phase sequence error, the higher the pressure, the automatic shutdown alarm when personnel enter the packing port by mistake.

The automatic intelligent packing machine adopts three-stage acceleration, when it encounters resistance, it will decelerate to two stages, when the scissors cut paper, it will automatically reduce to one stage, and the waste paper baler will automatically retreat at full speed.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience