number:+8619903886476 Mail:zyunfei87@gmail.com

number:+8619903886476 Mail:zyunfei87@gmail.com

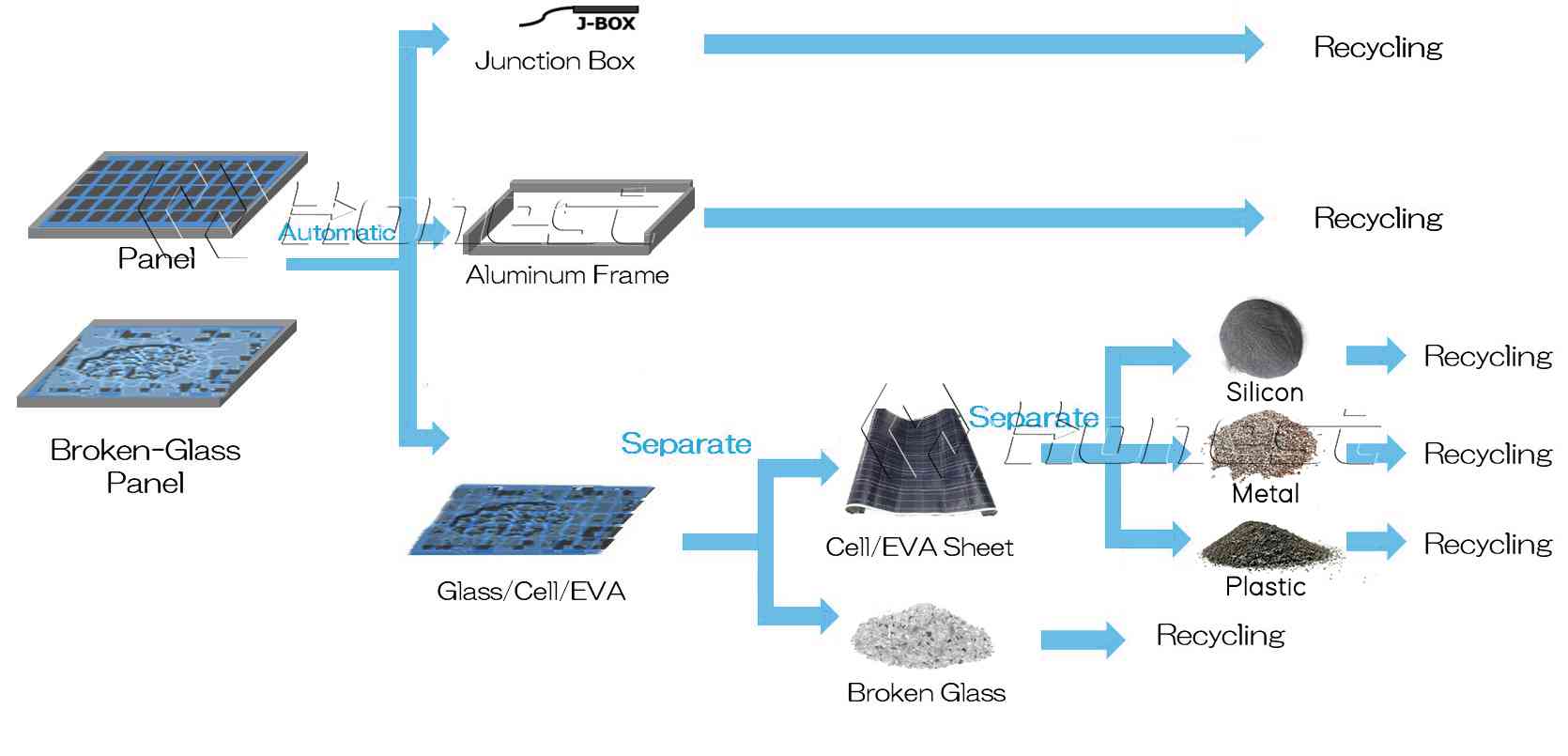

A dual-shaft shredder shreds solar panels into strips. Next, the material will enter the crusher. The crusher breaks the material into small pieces of 1-2cm. Feed by negative pressure, these small pieces will enter the fine grinder. Metal powder is screened out from one side of the air separator. Plastic and small amounts of metal enter the electrostatic separator. Our entire production line is in a negative pressure state, equipped with a pulse dust removal system. Solar photovoltaic panels have high recycling efficiency.

| Model | power(kw) | capacity (kg/h) | Weight (kg) |

|---|---|---|---|

| HN-SP300 | 102 | 300 | 15000 |

| HN-SP500 | 134 | 500 | 20000 |

| HN-SP1000 | 194 | 1000 | 30000 |

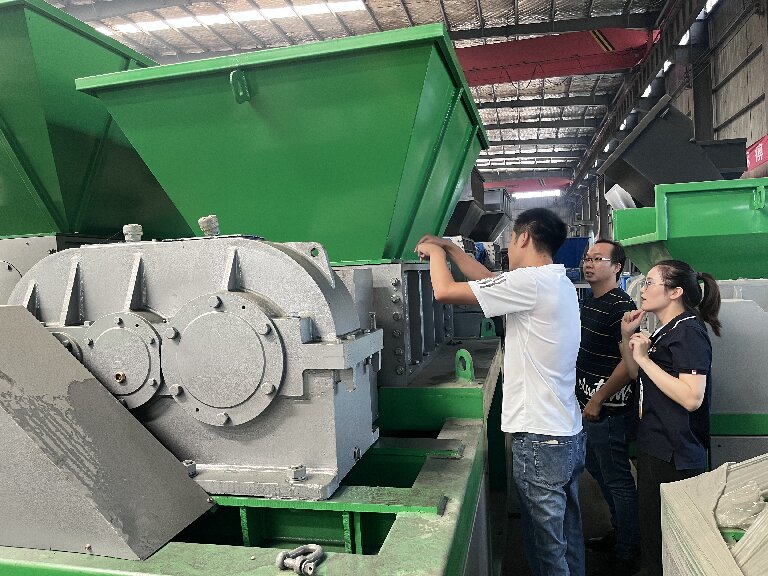

The double-shaft shredder is suitable for the waste recycling requirements of various industries, such as: electronic waste, plastic, metal, wood, waste rubber, packaging barrels, pallets, etc. There are many kinds of recycled materials, and the shredded materials can be directly recycled or further refined according to requirements. This series of double-shaft shredder has the characteristics of low speed, high torque and low noise.

The knife crusher is suitable for recycling all kinds of hard plastics, suitable for recycling all kinds of hard plastics, sample bottles, containers, plastic granules, tablets, materials, plastic barrels, PP plastic plates, cans, Pu pipes, waste plastics , Waste cables, waste plastic films, plastic bottles, ABS computer cases and other plastic products.

Airflow classifier is consisting of classifier, cyclone separator dust catcher, and draft fan. Material is up to classifier by strength of fan, separate fine material from coarse material under centrifugal force of grading turbine high speed rotation .and suitable fine material is collected by cyclone separator or dust catcher through grading impeller.

The dust collection system can be widely used for dust purification in various industrial fields such as hardware, cement, building materials, ceramics, electronics, chemical industry, shoe industry, casting, plastic, aluminum, metallurgy, electric power, leather, food, machinery and non-ferrous metals.

Electrostatic separation is to use the difference in electrical properties of materials in a high-voltage electric field to achieve the purpose of separation. Due to the different electrical properties of various materials and the different stress states, the trajectory of the materials when they fall is different, so that the mixture of metal and non-metal separate.

Solar panel recycling (photovoltaic) is an up and coming waste stream generated in both consumer and commercial elds of use. While demand may not be terribly high at the moment, there are many early-era solar power systems or solar PV systems that will soon be reaching their end of life cycle. Honest stands ready to deliver indust leading end of life management solutions for commercial and consumer solar energy systems.

If the material you want to know is not included, please contact us. We will give you the best quality solution.

On March 21, 2024, we will host an eye-catching live event – Shredder Live Show! This live broadcast will focus on four different types of shredders: small shredders, single-shaft shredders, double-shaft shredders, and heavy-duty shredders.…

Aluminum-plastic separation equipment is a new type of metal resource equipment. Aluminum-plastic separation equipment is widely used in aluminum-plastic recycling. Its main function is to separate aluminum and plastic using physical separation methods, which will…

Honest recently successfully customized a set of 800kg/h lithium battery recycling line for Greek customers. From design to production, and…

alaysia has always been one of the main markets for our shaft shredders. With our technological innovation and progress, more…

Once again, we sincerely thank our customers from Australia for trusting us and traveling thousands of miles to visit our…

The fully automatic PCB recycling equipment has a novel structure, is energy-saving and environmentally friendly, has one-time loading and intelligent…