Equipment Features

Main Applications:Professional paper and plastic recycling equipment

Raw Materials: Tetra pak /Coated paper /Kraft paper bag / Combibloc /Paper-plastic composite woven bag

Main Final Products:Paper,Plastic,Aluminum

If you want to start your recycling business, feel free to contact us.

This Tetra Pak recycling plant (Paper Plastic Recycling Line) uses advanced physical separation technology to efficiently separate and recycle the pulp, aluminum foil and plastic layers from Tetra Pak containers. The line integrates crushing, hydro pulping, screening, pressing and drying processes to ensure high purity and maximize the reuse value of the recovered materials.

Raw Material

The line is used to recycle paper-aluminum-plastic composite materials such as Tetra pak /Coated paper /Kraft paper bag / Combibloc /Paper-plastic composite woven bag.

Final Products

The final products are Paper (Packed pulp (Used for papermaking)), Plastic (Plastic film (Used for plastic granulation.)), Aluminum (Aluminum foil (Used for melting into ingots)). into ingots))

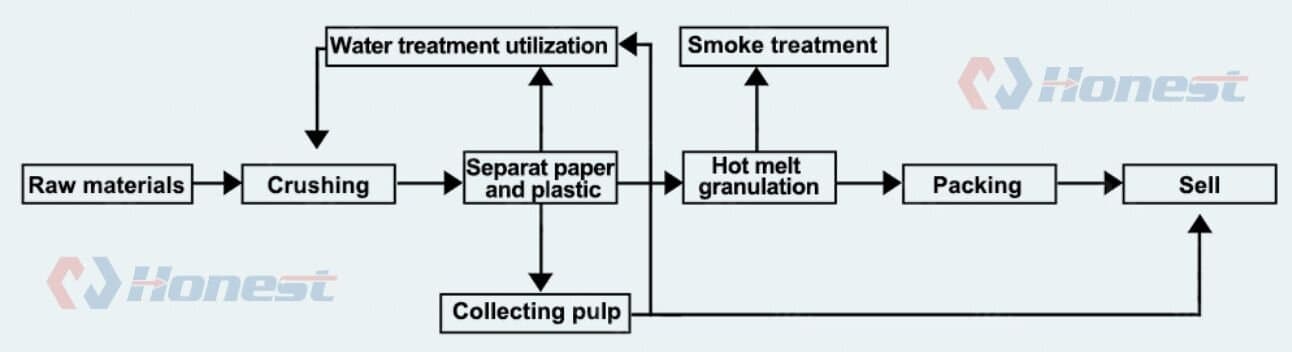

Paper Plastic Recycling Equipment Workflow

As a professional paper-plastic recycling equipment manufacturer, we can configure the production line according to customer needs. The composite materials such as Tetra Pak are crushed into small pieces for subsequent processing. Separate paper pulp from aluminum-plastic by hydraulic action. Separate pulp, aluminum-plastic and other materials of different sizes through screens with different apertures. Pressing and dewatering of the separated pulp. The pressed pulp is dried to obtain the finished pulp. Separate the separated aluminum-plastic mixture to get plastic film and aluminum foil.

Paper Plastic Recycling Line Brief Introduction

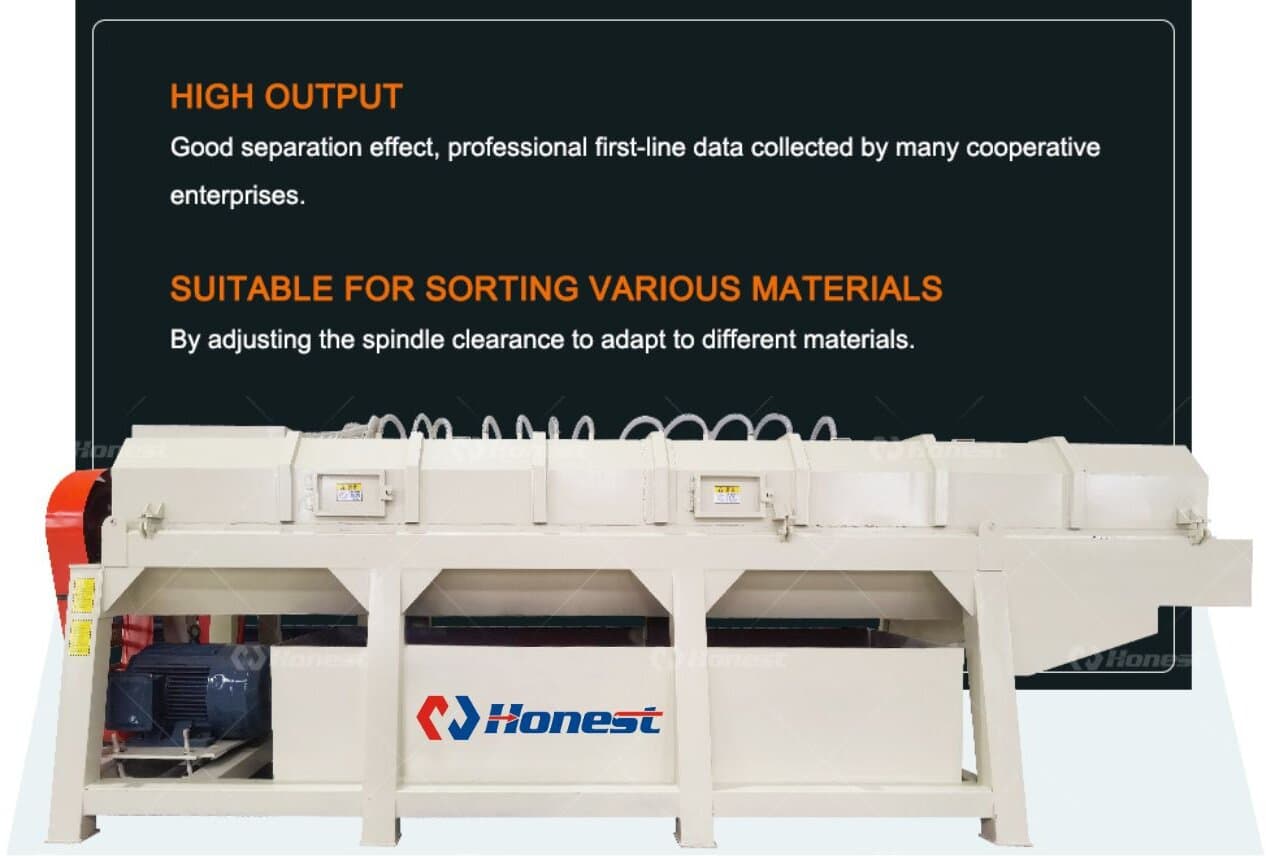

1.Paper Aluminum Separator

It is the main equipment of the production line. The working principle is that the motor drives the spindle to rotate at high speed. The spindle blade drives the material to move from the feeding end to the discharging end.

After years of research and development experience and cooperative development by cooperative manufacturers, water mixing and spindle sieve plate friction separation are adopted according to the characteristics of paper-plastic composite and paper-plastic mixture. This paper-plastic separator has passed through many cooperative manufacturers and customers.

| Function | Paper material | PE Coated paper, bulk paper, cow card | Paper covered bag |

| Main motor power (KW) | 110KW | 75KW-132KW | 55KW |

| Rated speed (r/min) | 380-560 | 380-560 | 380-560 |

| Mesh diameter (mm) Can be customized according to requirements |

8 | 8 | 8 |

| Thickness of sieve plate (mm) Can be customized according to requirements |

8 | 8 | 8 |

| Outlet (length x width) (m) | 0.8×0.8 | 0.8×0.8 | 0.8×0.8 |

| Diameter of slurry outlet (mm) | φ220×2 | φ220×2 | φ220×2 |

| Raw material processing capacity | 150-200t/24h | 1.5-3.5t/h | 11000-11500piece/h |

| Floor space: width x length (m) | 1.8×8 | 1.8×8 | 1.8×8 |

| Total (mm) | 3.3 | 3.3 | 3.3 |

| Outlet height (mm) | 1.1 | 1.1 | 1.1 |

| Height of pulp outlet (mm) | 0.8 | 0.8 | 0.8 |

2.Pulp Filter

In the pulping of waste paper, because of the different paper quality of waste paper, there is a large amount of slag. This machine can remove light and heavy sundries and decompose small pieces of paper in fibers, without blocking the sieve plate, and hard sundries will not hurt the sieve plate. The factory does not have to stop running for cleaning frequently, and it can also be used as a second pulping machine.It is mainly used for sorting tail pulp after fiber separator and pressure screen; The treated and sorted slurry is directly returned to the fiber separator or the slurry pool in front of the pressure screen for reuse.After sortingThe tailigs do not contain fiber, which meets the emission requirements of environmental protection.

| Model | 380 | 450 | 500 |

| Sieve Plate Length | L1.25xW0.61x2pcs | L1.5xW0.715x2pcs | L1.5xW0.795x3pcs |

| Electrical Machinery | 45kw-4 | 75kw-6 | 90kw-6 |

| Total Length Of Equipment | 3.75m | 4.15m | 5.85m |

| Equipment Width | 0.78m | 0.85m | 0.925m |

| Base Length | 3.0m | 3.5m | 5.16m |

| Slurry Inlet | 219 | 219 | 273 |

3.Pulp Dehydrator

The basic working principle of the pulp dehydato is: the particles rotate to a certain height with the drum, are thrown and fall by gravity, and are filtered through the screen to form a sieve. The roller screen is shaft driven, and the screen is steel wire woven net or high toughness nylon woven net. The ruler of the sieve holes can be configured according to the technological requirements.

| Model | Motor power | Screen density | Screen length | Weight | Output |

| TS-200 | 0.75 (KW) | 100 | 2.0(m) | 150(KG) | 500(kg) |

| TS-300 | 1.5 (KW) | 100 | 3.0(m) | 200(KG) | 750(kg) |

| TS-400 | 2.2 (KW) | 100 | 4.0(m) | 270(KG) | 1000(kg) |

| TS-500 | 2.2 (KW) | 100 | 5.0(m) | 350(KG) | 1300(kg) |

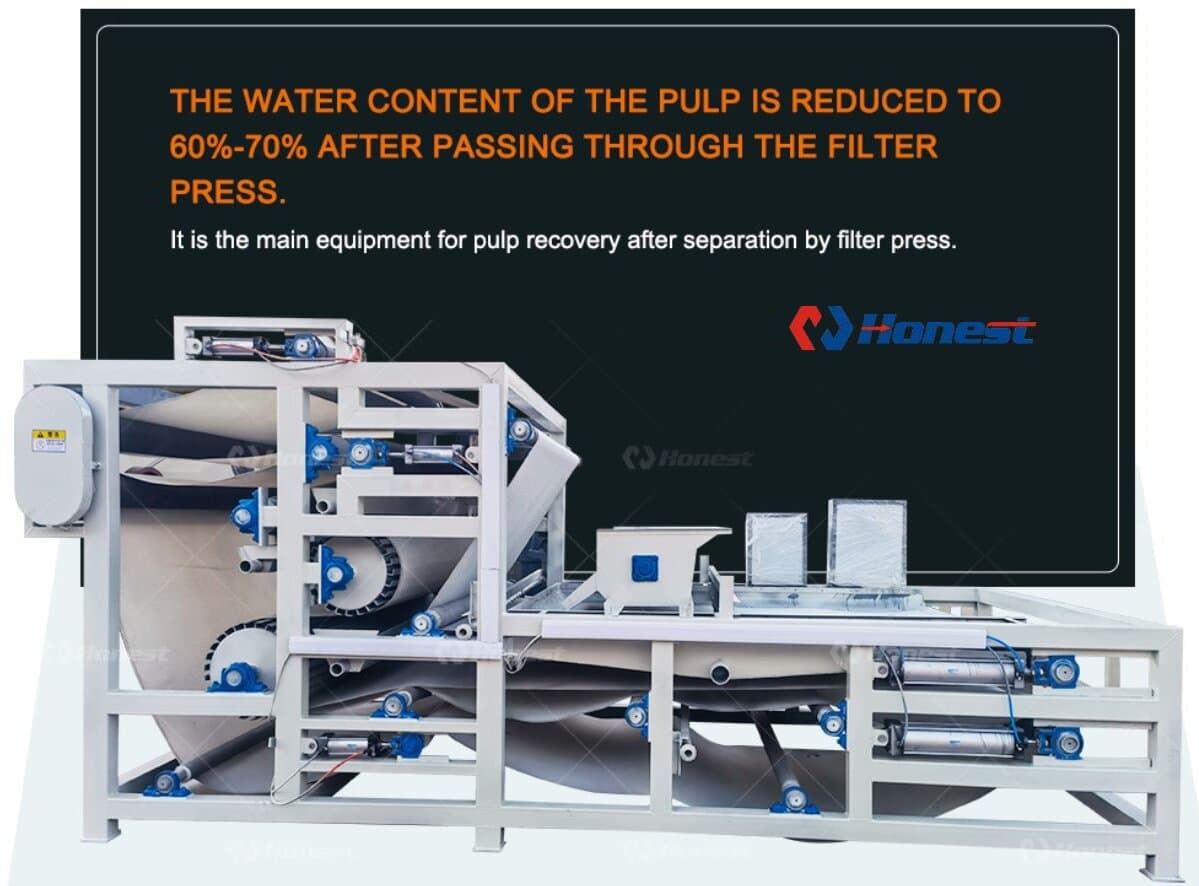

4.Pulp Filter Press

Pulp filter press is a mechanical equipment designed for the recycling of pulp separated by paper-plastic separator.

The pulp filter press uses the motor to drive the spindle to run and drive the polyester blanket. The pulp is transported to the filter press by the pump and evenly flows onto the polyester blanket. After being driven by the polyester blanket, it is squeezed between two layers of polyester blankets, and then squeezed and compacted by multiple pressing rollers, thus making cardboard for secondary uilization. The filtered clear water can be pumped by a water pump for recycling, thus reducing emissions and saving resources.

| Model | 1500 | 2000 | 2500 |

| Drive motor power (KW) | 4 | 4 | 5.5 |

| Polyester blanket specification | 1.5×11.3 | 2.0×11.3 | 2.5×11.3 |

| 1.5×12.7 | 2.0×12.7 | 2.5×12.7 | |

| Pulp handling capacity (t/d) | 35-55 | 42-62 | 50-70 |

| floor area (m) | 2.4×6.0 | 2.9×6.0 | 3.4×6.0 |

| Spindle speed (r/min) | 37-61.5 | 37-61.5 | 37-61.5 |

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476