Equipment Features

Main Applications:For recycling large household e-waste

Raw Materials:Such as scrap refrigerators, freezers, air conditioners, computers, televisions, washing machines

Main Final Products:Copper, Aluminum, Iron, Foam, Plastic

If you want to start your recycling business, feel free to contact us.

This waste refrigerator recycling plant adopts a multi-stage crushing and sorting process to efficiently recover copper, aluminum, iron, foam, plastic and other materials from waste refrigerators.Copper is separated from plastic with a separation efficiency of up to 99%.

Raw Material

It is mainly used for recycling waste refrigerators (including different sizes of household and commercial refrigerators with removed compressors), waste freezers, air-conditioners, computers, televisions, washing machines and so on.

Final Products

Valuable materials in the recycling of large household e-waste, such as copper, aluminum, iron, foam, plastic, etc.

Technical Parameters

| Model | HN-WR-1000 |

| Capacity | 25-100 units/hour (the production capacity is based on the processing of 120L-220L refrigerators, which can handle refrigerators with specifications above 220L) |

| Equipment size | 51m×13m×6.5m (Customizable) |

| Capacity reduction ratio of polyurethane foam | 1/5-1/8 |

| Iron recovery rate (weight%) | ≥99% |

| Recovery rate of copper and aluminum (weight%) | ≥98% |

| Plastic sorting rate (weight%) | 97% (<3% foam in recycled plastic) |

| The sorting rate of major materials shall be tested according to the enterprise standard of our company (Q/BAHI 001-2010) | |

| The emission of noise and particulate matter meets the requirements of relevant national standards (reference standards: GB12348-2008, GB 16297-1996) | |

Waste Refrigerator Recycling Plant Brief Introduction

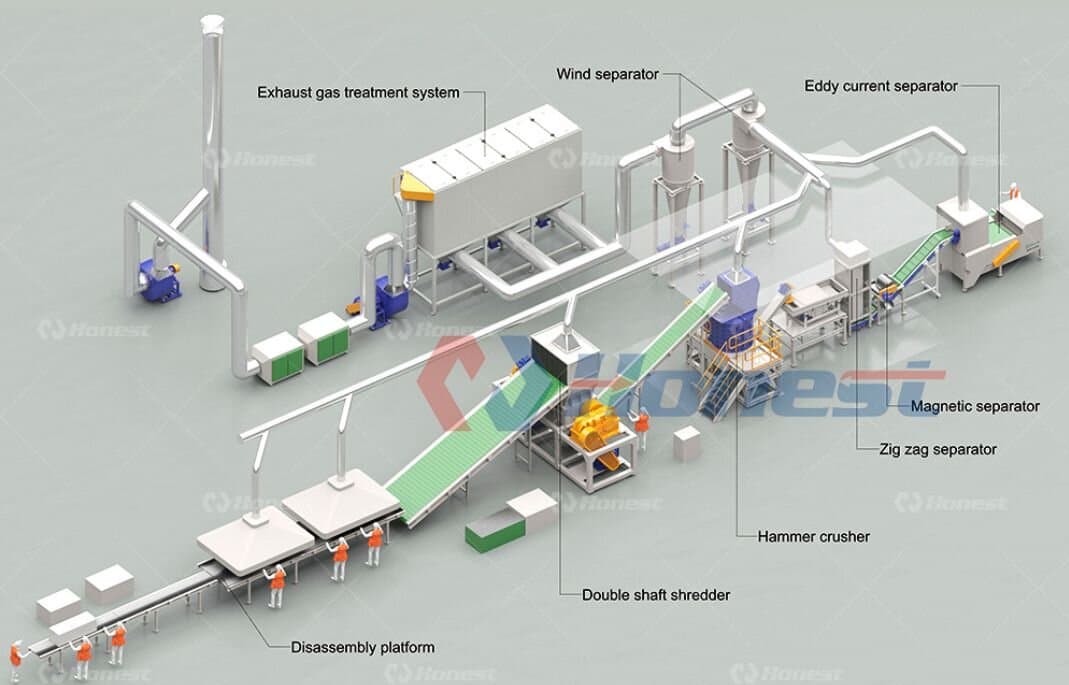

Disassembly platform: manual pre-processing of materials for disassembly.

Double shaft shredder: Preliminary shredding of materials.

Hammer crusher: crushes the material.

Zig zag separator: further separates materials.

Magnetic separator: separates magnetic materials.

Eddy current separator: separates non-ferrous metals.

Wind separator: Separation of materials with different densities by wind.

Exhaust gas treatment system: Treatment of exhaust gases generated in the production process.

Waste Refrigerator Recycling Equipment Workflow

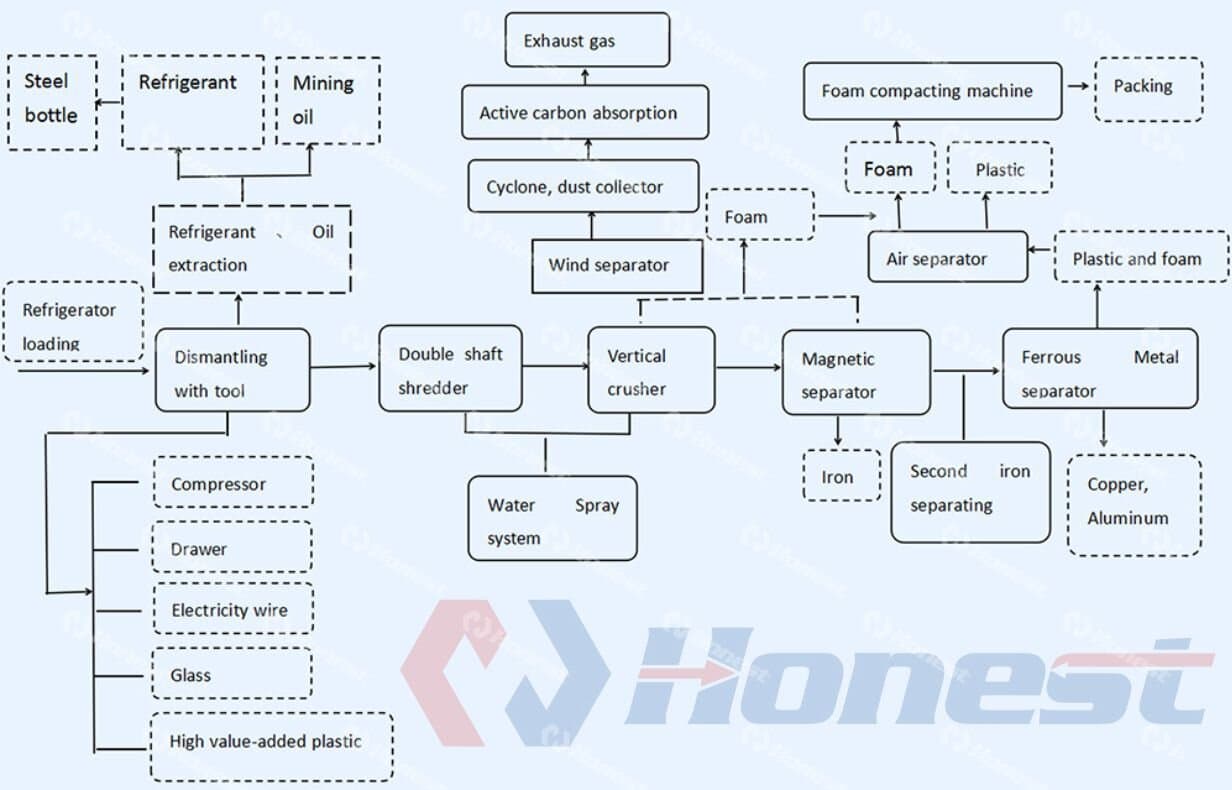

1.When the waste refrigerator (or freezer) is on the unpowered drum, disassembleit manually and remove the plastic and glass from the box.

2.According to different types of refrigerants, refrigerant recovery devices are usedto classify and recover refrigerants. Remove the compressor and condenser,etc.

3.The whole machine enters a double-shaft shredder for shredding and preliminarycrushing.

4.The materials enter the hammer crusher, and are crushed for the second timethrough crushing and kneading by the crusher.

5.At the same time of secondary crushing, part of polyurethane foam will beseparated into foam separator by air separation. Heavy materials such as plasticand metal enter the belt conveyor.

6.Materials crushed by plastic and metal are separated by magnetic separation onthe belt, and then enter eddy current separation.

7.Non-ferrous metals, such as copper and aluminum, are separated by eddycurrent,and plastic and foam materials are transported to the airflow separationsystem through belts to separate pure plastic and foam. Polyurethane foam iscompressed into blocks by a foam crusher.

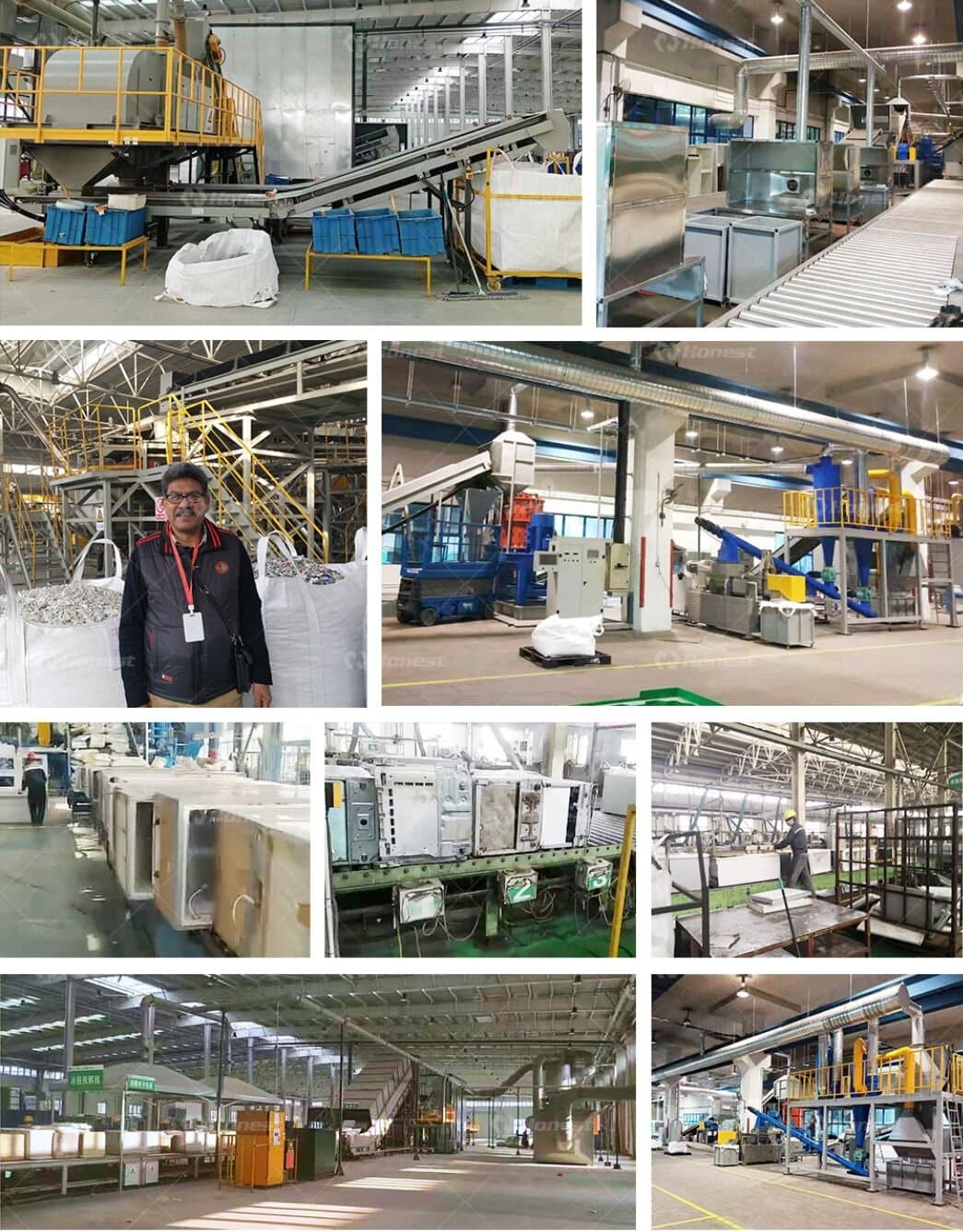

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience