Equipment Features

Main Applications:For paint stripping of metal surfaces

Raw Materials:Scrap Aluminum Can, Metal Paint Bucket, Baled UBC, etc.

Main Final Products:Carbonized UBC,Carbonized Metal

If you want to start your recycling business, feel free to contact us.

This Continuous UBC (Used Beverage Cans) Cans Paint Removing Plant is designed to efficiently remove coatings and paints from used beverage cans for treatment prior to melting for recycling. This paint removal process not only improves the quality of the recycled aluminum, but also increases the energy efficiency of the recycling process by reducing the amount of energy required during the melting stage. The equipment can be used to remove paint from metal surfaces such as aluminum cans and metal paint drums. The paint removal rate can reach more than 99.9%.

Raw Material

The equipment can be used for paint stripping treatment of metal surfaces such as Scrap Aluminum Can, Metal Paint Drum, Baled UBC, etc.

Final Products

Scrap Aluminum Can, Metal Paint Bucket, Baled UBC and other metal surfaces after paint stripping.

Technical Parameters

| Model | HN-LTL-1000 | HN-LTL-1200 | HN-LTL-1500 | HN-LTL-1800A | HN-LTL-1800B |

| Capacity (cans) kg/h | 800-1300 | 1300-1800 | 1800-2300 | 2300-2800 | 2800-3300 |

| Main Furnace Size (m) | 11.8×1.5×2.1 | 11.8×1.8×2.2 | 11.8×2.0×2.45 | 11.8×2.2×2.65 | 11.8×2.2×2.65 |

| Power (Standard) | 21.5kw | 25kw | 33.5kw | 42kw | 45.5kw |

| Equipment Weight (t) | 8 | 11 | 16 | 18.5 | 21.5 |

| Fuel | LPG, Diesel, natural gas, biomass, etc. | ||||

| Work Pressure | Micro negative pressure | ||||

UBC Cans Paint Removing Plant Brief Introduction

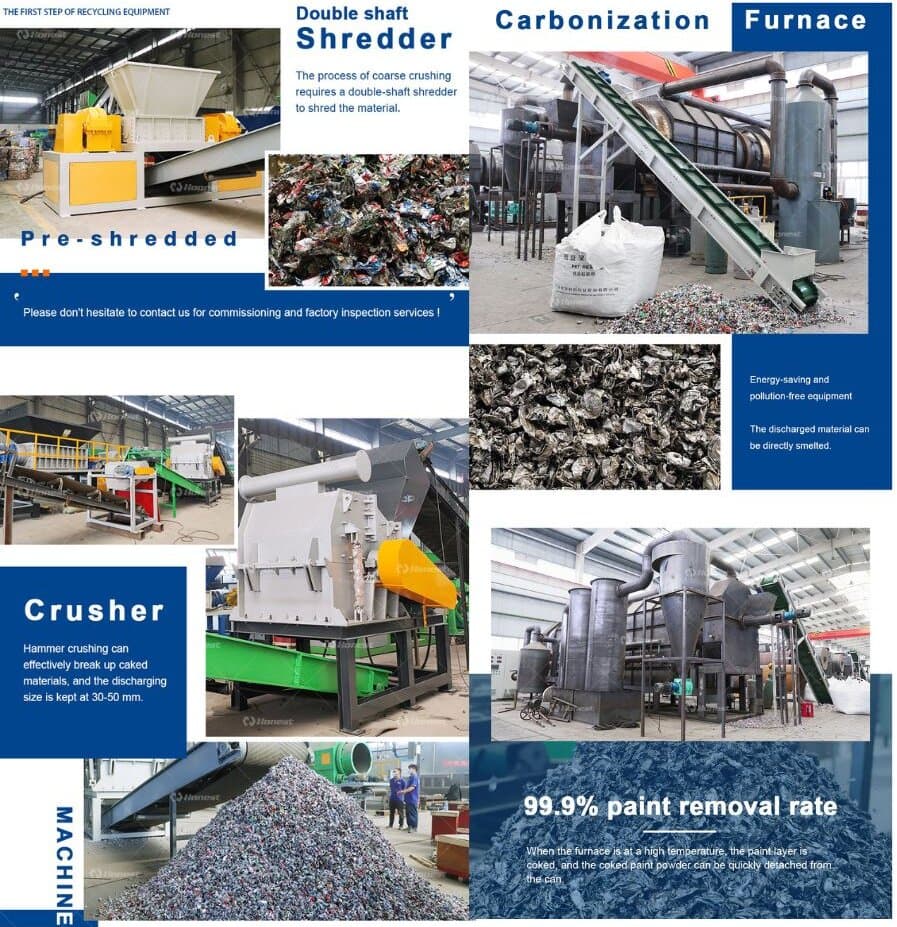

The complete UBC Cans Paint Removing Plant consists of a twin shaft shredder, hammer crusher, infeed system, charcoal oven, discharge system, control system and exhaust gas treatment equipment.

UBC Cans Paint Removing Equipment Workflow

The coarse crushing process requires a twin-shaft shredder to shred the material. Hammer crushing can effectively break up the lumpy materials, and the discharging size is kept at 30-50mm. the discharged materials can be directly smelted. The high temperature in the furnace causes the paint layer to caramelize, and the caramelized paint powder quickly falls off from the tank. Intelligent control system monitors and regulates the paint stripping temperature, pressure and body speed in real time, reducing the risk of manual intervention and misoperation. The sealing performance of the equipment is realized through the design of isolation belt, and the material is not deformed or oxidized under high temperature. The dust removal system includes filters, fans and exhaust ducts. The paint layer ranges from coked to powdered material and is processed together with the dust removal system.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience