Equipment Features

Main Applications:Processing a wide range of waste materials in different environments

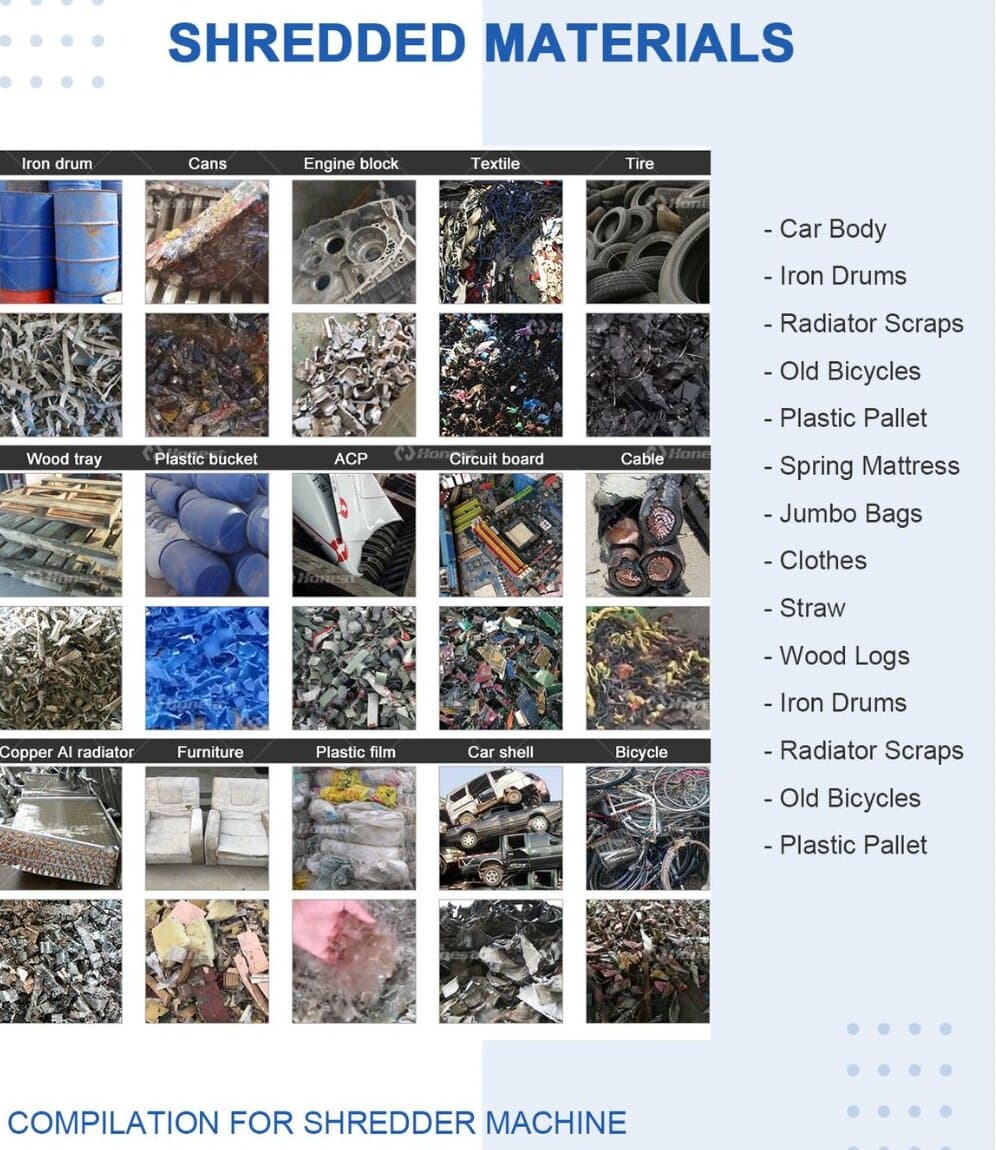

Raw Materials:Car Body,lron Drums,Radiator Scraps,Old Bicycles,Plastic Pallet, and more

Main Final Products:Reduced size pieces of various materials

If you want to start your recycling business, feel free to contact us.

This mobile twin shaft shredder is a highly versatile machine capable of handling a wide range of waste materials with customization options and free quotes available. It combines the powerful shredding capacity of a traditional twin-shaft shredder with the convenience of mobility, making it ideal for applications that require materials to be processed at different locations. It is typically powered by a diesel engine for stand-alone operation in remote locations, and an electric model is suitable for sites with a power source. The heavy-duty tracked chassis is designed to facilitate up and down ramps for flatbed trucks.

Raw Material

The machine can process a wide range of materials including Car Body,lron Drums,Radiator Scraps,Old Bicycles,Plastic Pallet,Spring Mattress,Jumbo Bags,Clothes,Straw,Wood Logs,lron,Drums,Radiator Scraps,Old Bicycles,Plastic Pallet,metals, plastics, textiles, wood, paper, used household appliances, pipes, used tires, and a wide range of kitchen waste, household waste, RDF derivatives, garden waste, and more.

Final Products

The main final products of Mobile Double Shaft Shredder Machine include size-reduced Car Body,lron Drums,Radiator Scraps,Old Bicycles,Plastic Pallet, and more. These products can be easily recycled, reused or further processed after shredding.

Technical Parameters

| Model | HN-SS-1600 | HN-SS-2000 |

| Blade Diameter | 0.53 m | 0.6 m |

| Blade Thickness | 0.1 m | 0.1 m |

| Blade Number | 16 Pieces | 20 Pieces |

| Spindle Diameter | 0.27 m | 0.31 m |

| Power (KW) | 75*2 | 110*2 |

| Input Opening Size | 2.5×2.0x1.4 m | 3.0×2.1×1.5 m |

| Dimension L/W/H | 4.8×2.7×3.7 m | 5.6×3.0x4.0 m |

Key components of Mobile Double Shaft Shredder Machine

The mobile shredder is equipped with a heavy-duty tracked chassis with a travel speed of 1km/h and a strong barrier-crossing capability. It can be customized with a planetary gearbox. The principle of operation involves a feed hopper, twin shaft cutting system, PLC control system, unloading conveyor system and power system.

The shredder can be operated remotely or manually via the controller and includes remote diagnostics with a focus on safety and stability via the hydraulic drive system and pressure detection system in the various drive components.

The feed hopper prevents material splashing, while the dual-axis cutting system uses customizable blades. The power system utilizes a well-known Chinese motor brand and can be configured according to the customer’s specifications. The unloading conveyor system has a separate power system that bolts integrally to the shredder for easy pull-out as a unit. The machine also features a folding conveyor with high stacking height and strong conveying capacity, a large diesel tank for on-site refueling, and PLC control with a pressure detection system to ensure safe and stable operation. The heavy-duty tracked undercarriage is designed to facilitate up and down ramps for flatbed trucks. Features include a large feed hopper, efficient rotary knife design, PLC control with blade reversal for protection, high-temperature treated alloy steel knives, easy knife replacement, and oversized pulleys for increased inertia and energy savings.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience