Eddy Current Separator (ECS) Equipment Safety Guidelines

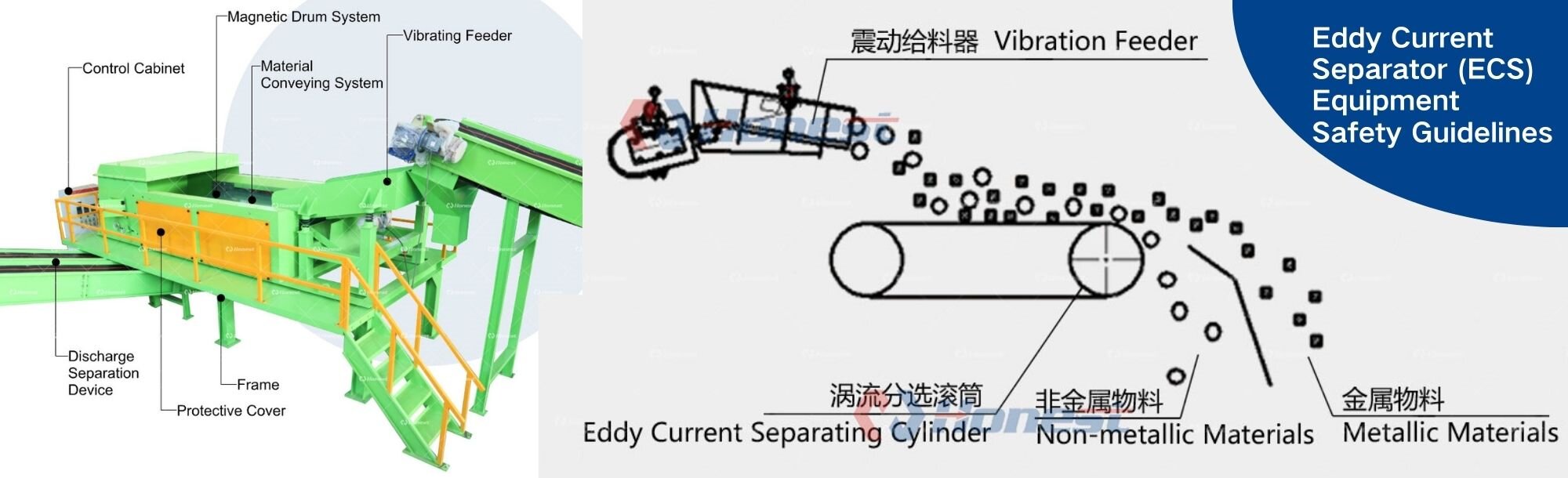

The Eddy Current Separator is a high-efficiency system designed for recovering non-ferrous metals such as aluminum and copper from mixed waste streams. By using a fast-rotating magnetic rotor made of high-strength permanent magnets, the machine creates a rapidly alternating magnetic field. When conductive metals pass through this field, eddy currents are induced within the material. These currents generate a secondary magnetic field that repels the metals in the opposite direction of the rotor’s magnetic field, causing them to be thrown forward into a separate discharge path. Non-metallic materials such as plastics, glass, and paper remain unaffected, allowing for clean and precise separation.

This technology is widely used in aluminum recycling, copper recovery, municipal waste sorting, and electronics dismantling. With stable performance, low energy consumption, and high separation purity, the Eddy Current Separator is a key piece of equipment for modern recycling and environmental protection industries.

Eddy Current Separator (ECS) Equipment

Eddy Current Separator (ECS) Equipment

Because the separator uses a powerful permanent-magnet rotor, operators must be aware of the strong magnetic field around the machine. Personnel with pacemakers, metal implants, or magnetic-sensitive devices must not approach the equipment. Iron tools, sharp metal objects, magnetic storage media (such as hard drives, credit cards, and tapes), and electronic watches should be kept at least one meter away to prevent magnetization or data loss. During installation, transport, or maintenance, no ferromagnetic objects should be placed above the rotor area. Maintenance work must always be performed with the main power supply completely disconnected.

For reliable operation, the machine should be installed on a leveled concrete foundation using anchor bolts and operated in environments below 200 m altitude, ambient temperatures from 0–40°C, and humidity below 90% at 25°C. The equipment must be protected from rain, snow, and corrosive gases. When starting the system, the belt motor should run first, followed by the magnetic rotor; during shutdown, the magnetic rotor must stop first to avoid material damage inside the separator.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Chinese New Year Holiday Schedule and Production Planning Notice

- Why Shredded Paper Is Replacing Plastic Fillers

- Can Copper and Aluminum Be Separated from Mixed PCB Metal Powder?

- What Materials Are Best Processed by a Spiral Shredder

- Solar Panel Frame & Junction Box Removal Machine

- How Cable Granulators Separate Copper from PVC

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export