Details and Maintenance of Spiral Shredder Crusher

Before operating a newly delivered spiral crusher, customers should first inspect all bolts on the moving and fixed blades. New bolts may slightly loosen during transportation or in the early running period due to initial elastic stretching, vibration, and the gradual fitting of components. If any bolt is loose, the machine must not be started or loaded with material. For stable performance, we recommend tightening all blade bolts daily during the first 1–2 weeks. After the components reach a stable preload, loosening will significantly decrease and the machine will run reliably.

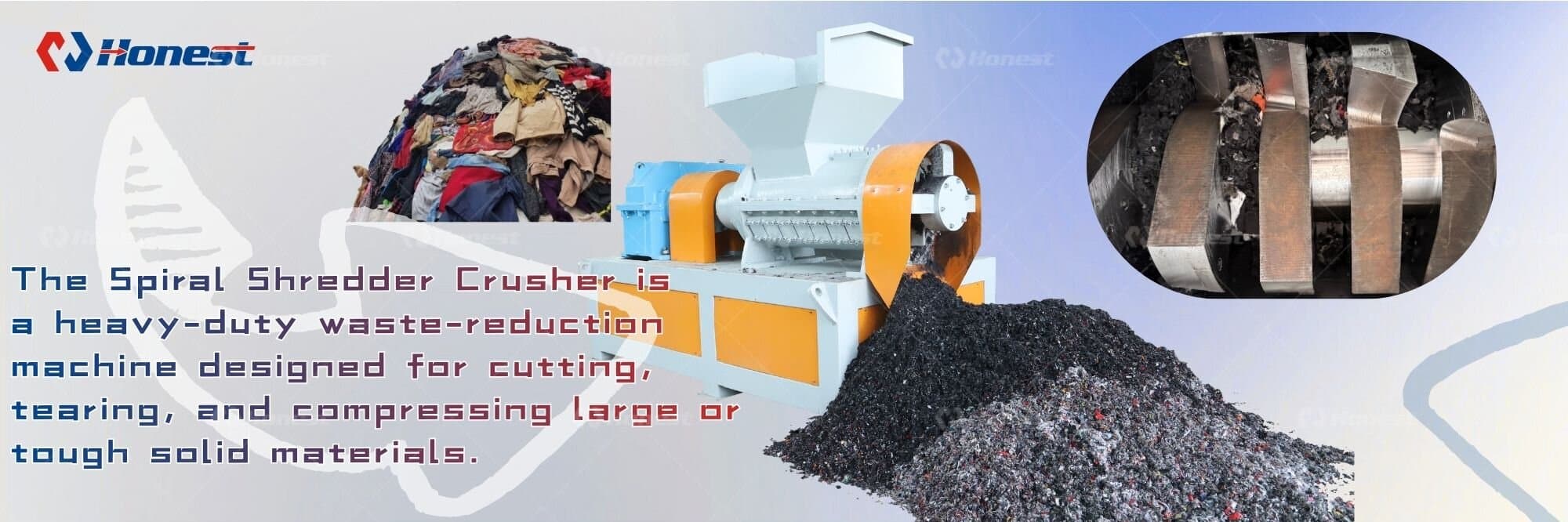

The Spiral Shredder Crusher is a heavy-duty waste-reduction machine designed for cutting, tearing, and compressing large or tough solid materials. It operates at low speed with high torque, allowing the spiral blades to firmly grip various waste materials and break them down efficiently. This makes it highly effective for bulky, flexible, or mixed wastes that traditional high-speed crushers cannot handle.

Spiral Shredder Crusher

Spiral Shredder Crusher

The machine consists of a reinforced crushing chamber, a single spiral shaft with hard-alloy blades, fixed counter-blades, an optional discharge screen, and a high-power motor with a reduction gearbox. During operation, material is fed by a conveyor or loader into the crushing chamber. The rotating spiral blades hook and pull the material into the cutting zone, where it is sheared and compressed between the moving and fixed blades. The crushed output is discharged through the bottom or through a screen that controls the final particle size—typically available in 10 mm, 30 mm, or 50 mm options.

With its low-speed, high-torque design, the spiral crusher delivers strong crushing force with reduced noise, minimal dust, and stable continuous operation. It handles soft, elastic, or easy-to-wrap materials—such as textiles, ropes, woven bags, film bales, packaging waste, and mixed municipal waste—without the entanglement problems commonly seen in high-speed shredders. The unique spiral blade design provides excellent anti-winding performance, making it suitable for complex waste streams.

Compared with hammer mills and standard single-shaft shredders, the spiral crusher offers superior performance in processing flexible or mixed waste, delivering higher throughput, better volume reduction, and more stable operation. It is ideal for coarse crushing, pre-treatment, and size-reduction in waste-recycling lines. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Chinese New Year Holiday Schedule and Production Planning Notice

- Why Shredded Paper Is Replacing Plastic Fillers

- Can Copper and Aluminum Be Separated from Mixed PCB Metal Powder?

- What Materials Are Best Processed by a Spiral Shredder

- Solar Panel Frame & Junction Box Removal Machine

- How Cable Granulators Separate Copper from PVC

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export