Utilize mechanical equipment to depaint aluminum cans

The colorful coating on the surface of used aluminum cans poses a major challenge in the aluminum recycling process. Although the coating accounts for only 2–3% of the total weight, skipping the de-coating step and directly melting the cans can lead to several serious issues. First, harmful impurities and gases are introduced into the molten aluminum, compromising the quality of the alloy and making it unsuitable for high-grade reuse, which in turn reduces economic benefits. Second, the combustion of the paint layer releases toxic fumes, polluting the environment and posing health risks to workers. Third, the burning of the coating causes oxidation of the aluminum, which reduces the recovery rate and increases energy consumption during smelting.

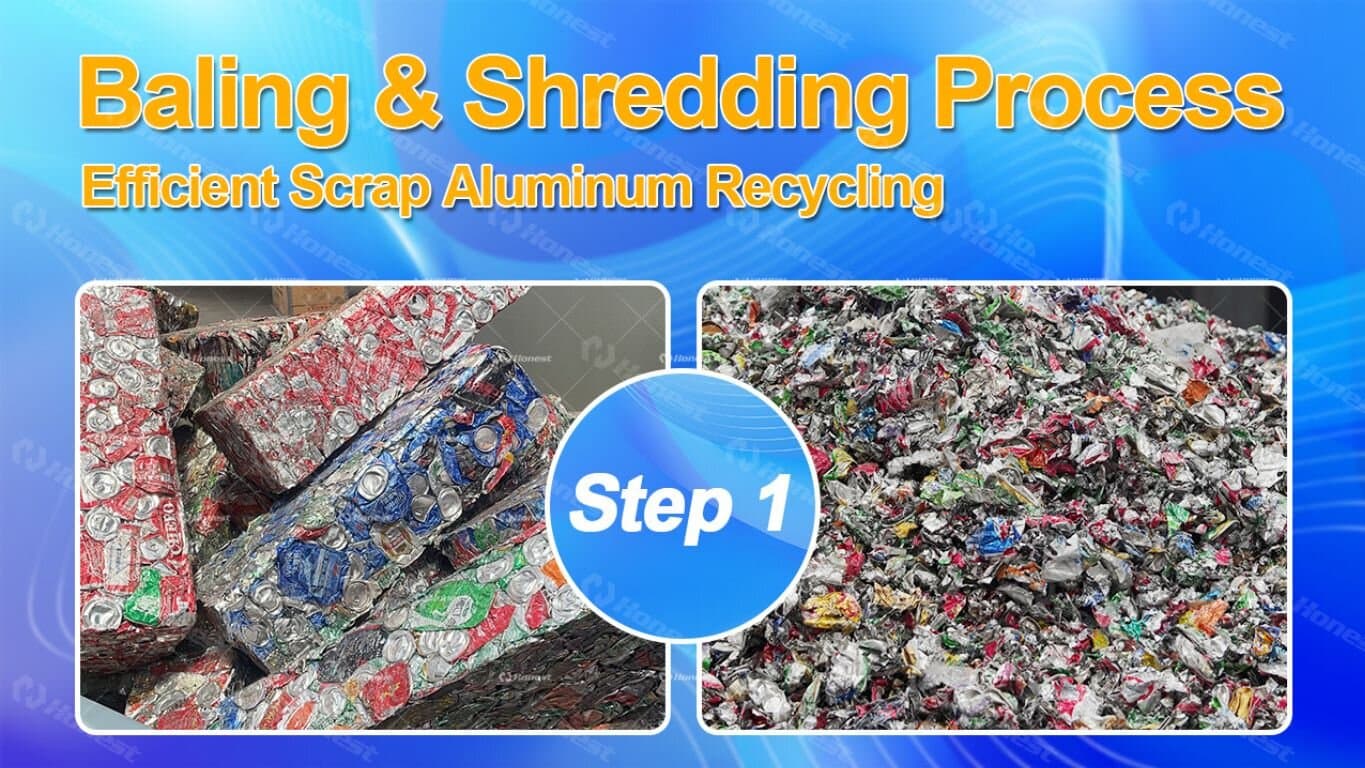

To improve the purity of recycled aluminum and minimize pollution during melting, our factory has developed a mechanized aluminum can de-coating system featuring a continuous carbonization furnace. The process begins by crushing compressed or flattened aluminum cans into small particles, which facilitates the subsequent heat treatment. Then, a screw feeder conveys the crushed material evenly and continuously into the carbonization furnace. Inside the sealed chamber, the aluminum is heated to a high temperature of approximately 500–600°C, causing the coating to carbonize and detach rapidly, ensuring thorough de-coating.

UBC Aluminum Cans Systematic De-coating Process

UBC Aluminum Cans Systematic De-coating Process

With clean de-coating results, easy operation, compliance with environmental standards, and reduced labor demands, our UBC Aluminum Cans De-coating Plant stands out for its excellent performance. For customized solutions or on-site testing videos, feel free to contact us for more information.

Contact Tel: +86 199 0388 6476

Contact Email: hnhonest.zack@gmail.com

Related News

- How Cable Granulators Separate Copper from PVC

- Lithium-Ion Battery Recycling Line with Nitrogen Protection System

- A2 & FR ACP Aluminum Plastic Separation Recycling Machine

- Efficient Shredding Solutions for Waste Textiles and Used Clothing Recycling

- Solar Pv Panel Recycling System Pyrolysis-Based for Extracting Silicon

- How Should Different Types of Scrap Cables Be Recycled

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export