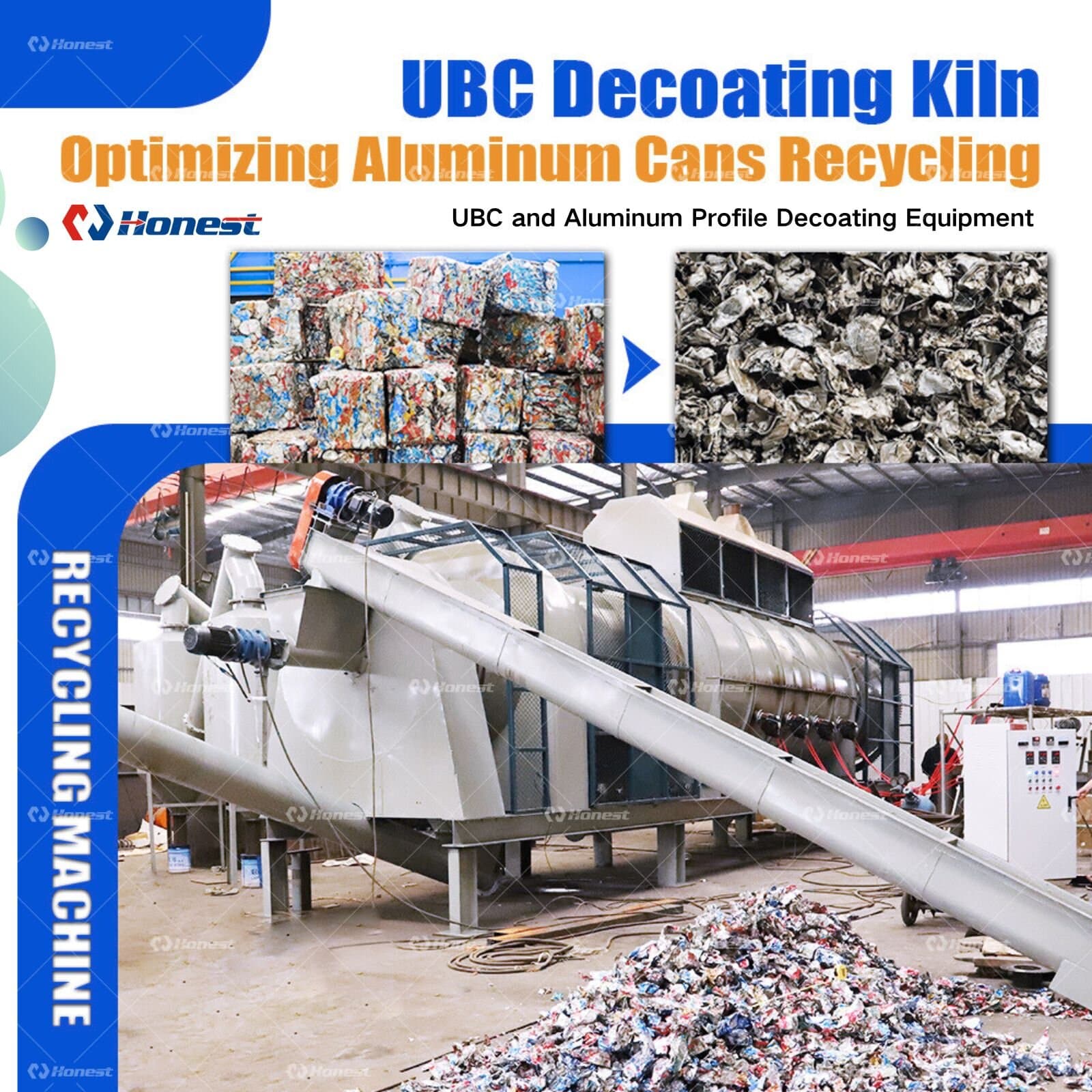

UBC and Aluminum Profile Decoating Equipment

For aluminum smelters, clean feedstock means higher melt quality, lower dross generation, and better yields. This is why smelters consistently prefer UBC and aluminum profiles with surface paint and coatings already removed. For recyclers handling used beverage cans and coated aluminum profiles, investing in professional decoating equipment is the most effective way to increase resale value and profitability. Below is a streamlined introduction to the working process and core configuration of modern UBC and aluminum profile decoating solutions.

The recycling process starts with understanding the incoming material condition. Loose UBC or aluminum profiles can be fed directly into the line, while baled scrap must first be loosened using a bale breaking machine to ensure smooth downstream processing. The material is then conveyed into a dual-shaft shredder for pre-shredding, followed by a metal crusher for secondary size reduction. This two-stage shredding and crushing process ensures uniform particle size, improves heat transfer efficiency, and prepares the aluminum scrap for the critical decoating stage.

UBC and Aluminum Profile Decoating Equipment

UBC and Aluminum Profile Decoating Equipment

The core of the system is the UBC and aluminum profile decoating furnace, which uses high-temperature pyrolysis technology to remove surface coatings without damaging the aluminum substrate. Inside a sealed, low-oxygen rotary furnace, the shredded aluminum is heated to approximately 450–550°C. At this temperature, paints, lacquers, inks, and organic residues are thermally decomposed into harmless gases and minimal ash. The aluminum itself remains intact, with a clean surface and no oxidation, resulting in high-purity scrap suitable for direct melting.

This continuous rotary decoating process offers stable operation, high throughput, and consistent treatment quality. By eliminating surface contaminants before smelting, the system significantly reduces impurities, lowers energy consumption during melting, and improves the overall recovery rate of aluminum. The treated UBC and aluminum profiles command higher market prices and meet the strict feedstock requirements of modern aluminum smelters.

As a professional manufacturer of recycling machinery and complete aluminum recycling solutions, we provide customized UBC and aluminum profile decoating systems based on material type, capacity, and site conditions. Each machine and production line is fully tested with real materials before delivery to ensure stable, reliable performance. For more equipment details or to arrange an on-site or virtual factory visit, please contact our sales team—we are ready to design the most efficient decoating solution for your aluminum recycling operation.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Solar Panel Recycling Is Becoming a Strategic Resource Industry

- Chinese New Year Holiday Schedule and Production Planning Notice

- Why Shredded Paper Is Replacing Plastic Fillers

- Can Copper and Aluminum Be Separated from Mixed PCB Metal Powder?

- What Materials Are Best Processed by a Spiral Shredder

- Solar Panel Frame & Junction Box Removal Machine

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export