Details Single & Bifacial Solar Panel Recycling Machine

As the volume of retired photovoltaic modules increases, efficient recycling of single-glass and double-glass (bifacial) solar panels has become essential. Although these panels appear similar, their internal structures and dismantling requirements are very different, so a specialized recycling process is required for each type.

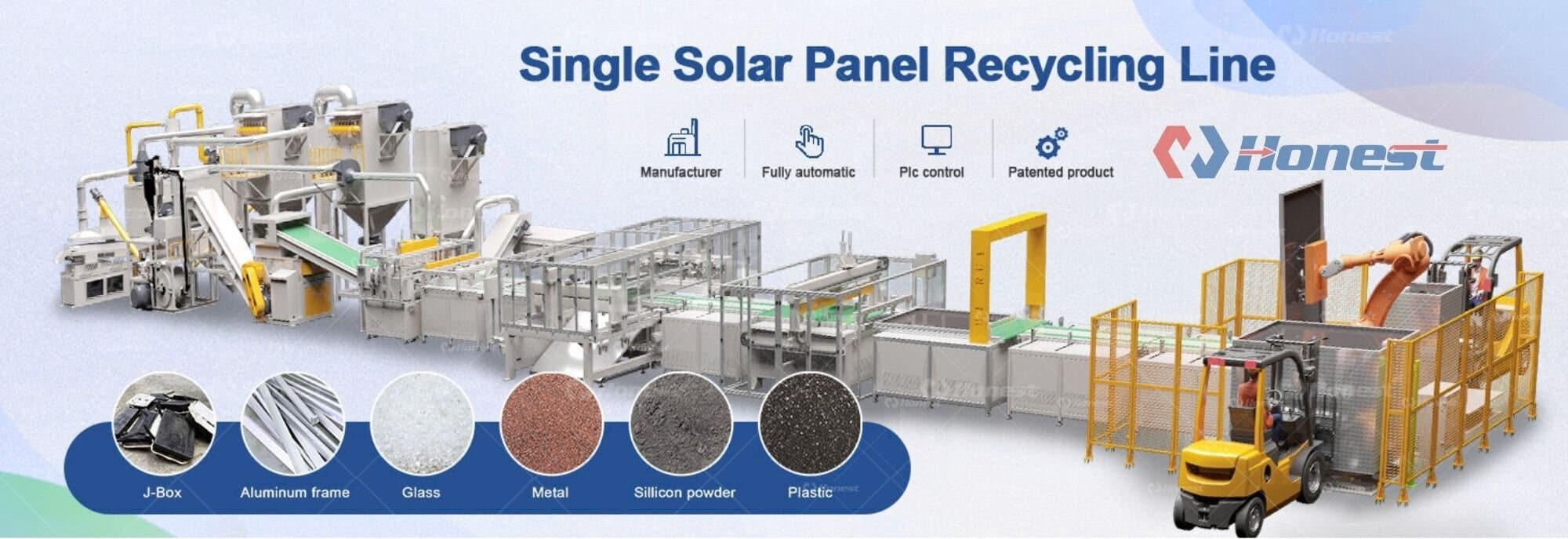

Our Single / Bifacial Solar Panel Recycling Line is designed to process both module structures with high efficiency—from automatic loading and deframing to shredding, crushing, separation, and final material recovery. The system allows recyclers to obtain high-purity aluminum, glass, copper, plastics, and silicon while reducing labor and improving operational stability.

The equipment supports real-time factory trial runs, enabling customers to observe actual throughput, operating efficiency, and the quality of recovered materials. This provides practical reference for companies engaged in solar panel recycling, renewable energy waste management, or those entering the PV recycling business.

Single & Bifacial Solar Panel Recycling Line — Complete Process and Technical Specifications Both panel types follow a general flow of automatic feeding → frame removal → junction box removal → crushing → separation, yet single-glass and bifacial panels require different approaches. Single-glass modules contain a backsheet and require precise glass removal, while bifacial panels consist of double glass layers and demand a stronger shredding and glass-glass separation process. The system is built for stable, continuous operation and can be configured as single-line or 1-to-2 high-capacity layout.

Double-Glass (Bifacial) Solar Panel Recycling Line This line handles framed bifacial panels with widths up to 1300 mm and lengths 1000–2400 mm, regardless of surface damage. Two capacities are available: 50–60 pcs/hour (1–2 t/h) or 100–120 pcs/hour (4–5 t/h). Output data (sample only): aluminum frame recovery ≥90% with ≥95% purity; copper ≥95% with ≥95% purity; plastic powder ≥95% with ≥90% purity; silicon recovery around 80% with ~30% silicon content in mixed powder.

Optional features include robotic pallet unloading, linkage with the single-glass front-section equipment for automated frame and glue-box removal, and a 1-to-2 configuration for higher output without significant increase in floor space.

We offer two widely used briquetting solutions designed for compressing metal powders, chips, and loose scrap into high-density blocks for easy handling, smelting, and transportation. These machines significantly reduce storage volume, minimize oxidation loss during melting, and improve the overall recycling value of metal waste.

Single-Glass Solar Panel Recycling Line This line processes single-glass panels ranging 1000–2400 mm long and 800–1300 mm wide, with deformation ≤30 mm and glue strip height ≤2.5 mm. Capacity is 50–60 pcs/hour (0.5–2.1 t/h depending on panel size), with 97% operational stability.

Sample output data: aluminum frame removal ≥99% with ≥98% purity; glass removal 90–98% with ≥95% purity; copper recovery ≥95% with ≥95% purity; plastic powder ≥95% with ≥90% purity; silicon recovery ~95% with 45–60% silicon content depending on process configuration.

Core components include Siemens PLC and servo motors, Siemens-Beide three-phase motors, Airtac pneumatics, Omron sensors, and Konic reducers. The line uses 0.6–0.8 MPa / 2.5 m³/min compressed air. Conveyors are fully sealed to reduce dust escape. Layout drawings and manuals are provided after order confirmation.

Advanced functions include robotic loading, 3D line-scan modeling to identify module dimensions and glue-box positions, and an upgraded glue-box removal system that automatically adapts to different box counts and directions.

Key Advantages of the Integrated Recycling Line The combined Single & Bifacial Solar Panel Recycling Line delivers high-efficiency dismantling, stable processing, and high-purity material recovery. Automated feeding, AI vision recognition, robot-assisted handling, and precision dismantling systems significantly reduce manual labor. High-quality components from Siemens, Airtac, Omron, and Konic ensure durability and low maintenance. The entire line supports modular configuration, automatic operation, and flexible customization to meet different capacity, voltage, and installation requirements.

This solution enables recyclers to efficiently convert retired solar modules into valuable resources, offering strong performance for both established recycling plants and new entrants in the PV recycling industry. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Chinese New Year Holiday Schedule and Production Planning Notice

- Why Shredded Paper Is Replacing Plastic Fillers

- Can Copper and Aluminum Be Separated from Mixed PCB Metal Powder?

- What Materials Are Best Processed by a Spiral Shredder

- Solar Panel Frame & Junction Box Removal Machine

- How Cable Granulators Separate Copper from PVC

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export