Equipment Features

Main Applications:Process motor rotor, stator, wire bundle and transformer under 20cm

Raw Materials:Scrap motor rotors, stators, wire harnesses and transformers

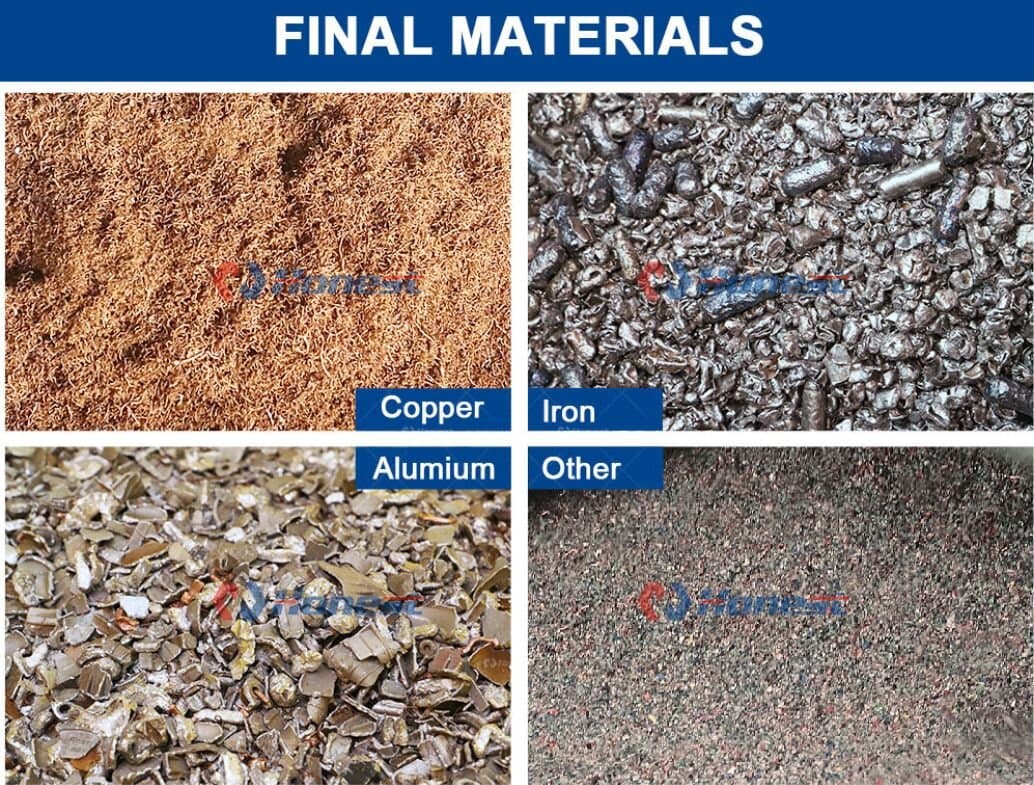

Main Final Products:Copper,Iron,Other mixtures

If you want to start your recycling business, feel free to contact us.

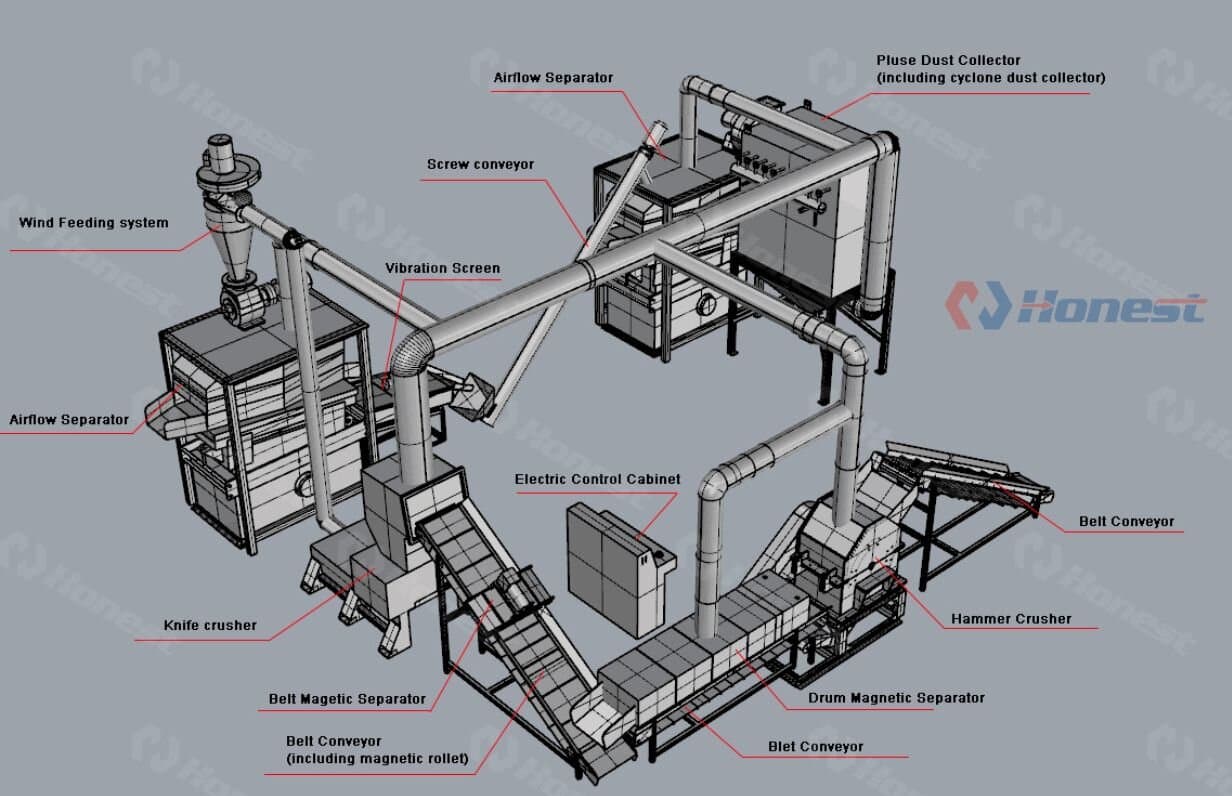

We can not only produce copper drawing equipment for scrap motor stator cutter for small investment, but also provide the whole production line (including hammer crusher, knife crusher, magnetic separator, air separator, pulse dust collector and other auxiliary machines) for recycling scrap motor, stator and rotor.

Raw Material

The Scrap Metal Motor Stator Rotor Recycle Machine can process scrap electric rotor, stator, wire bundle and transformer from household appliances, electric tools, etc. After processing, you can get copper, iron and non-metal.

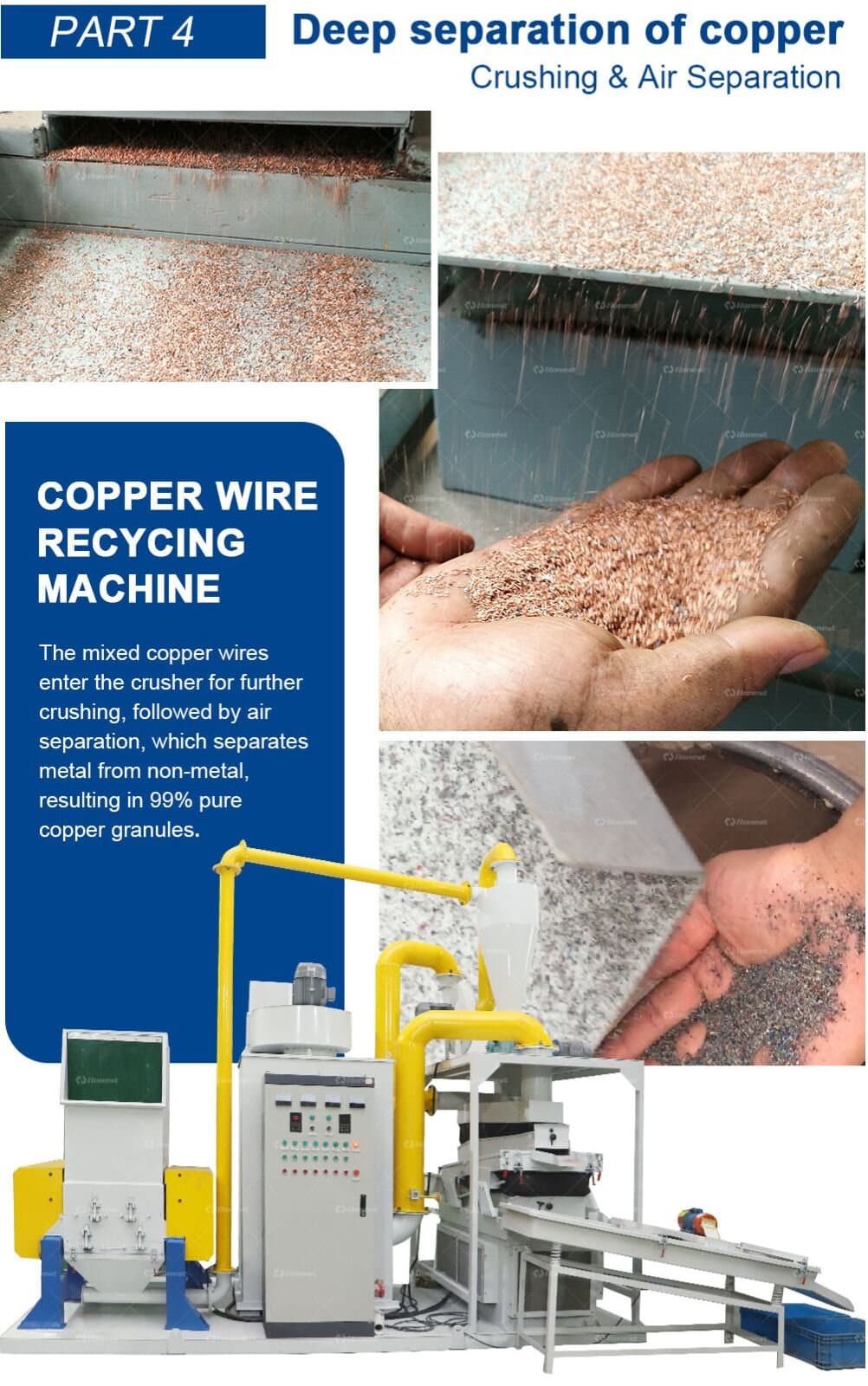

Final Products

Scrap Motor Stator Recycling Plant is a specialized facility designed to efficiently recover valuable metals, mainly copper , iron and other mixtures, from discarded motor stators.

Technical Parameters

| Model | HN-MR-1000 | HN-MR-2000 | HN-MR-3000 | HN-MR-5000 |

| Capacity (Kg/h) | 1000 | 2000 | 3000 | 5000 |

| Power (Kw) | 177 | 303 | 345 | 493 |

| Weight (ton) | 26.5 | 47 | 50.5 | 67.5 |

| Size (m) | 25*6*6 | 40*6*6 | 45*6*6 | 50*10*6 |

| Sorting Efficiency | 98% | 98% | 98% | 98% |

| Dust Removing Efficiency | 99% | 99% | 99% | 99% |

| NOTE: Working Voltage: 380V, 415V, 440V or can be customized.

(If you want more detailed parameters and quotations, please contact us) |

||||

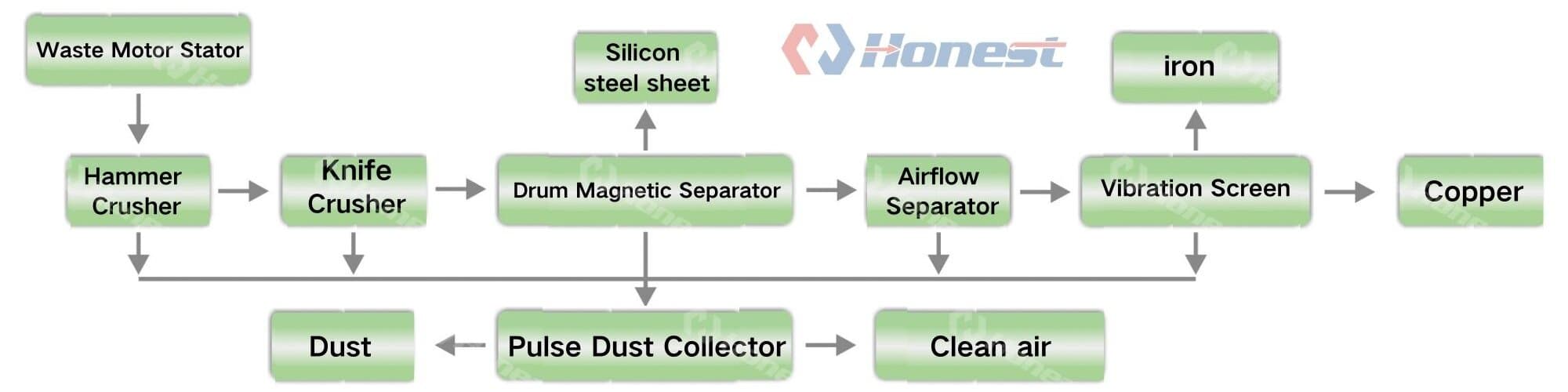

Scrap Motor Stator Recycling Equipment Workflow

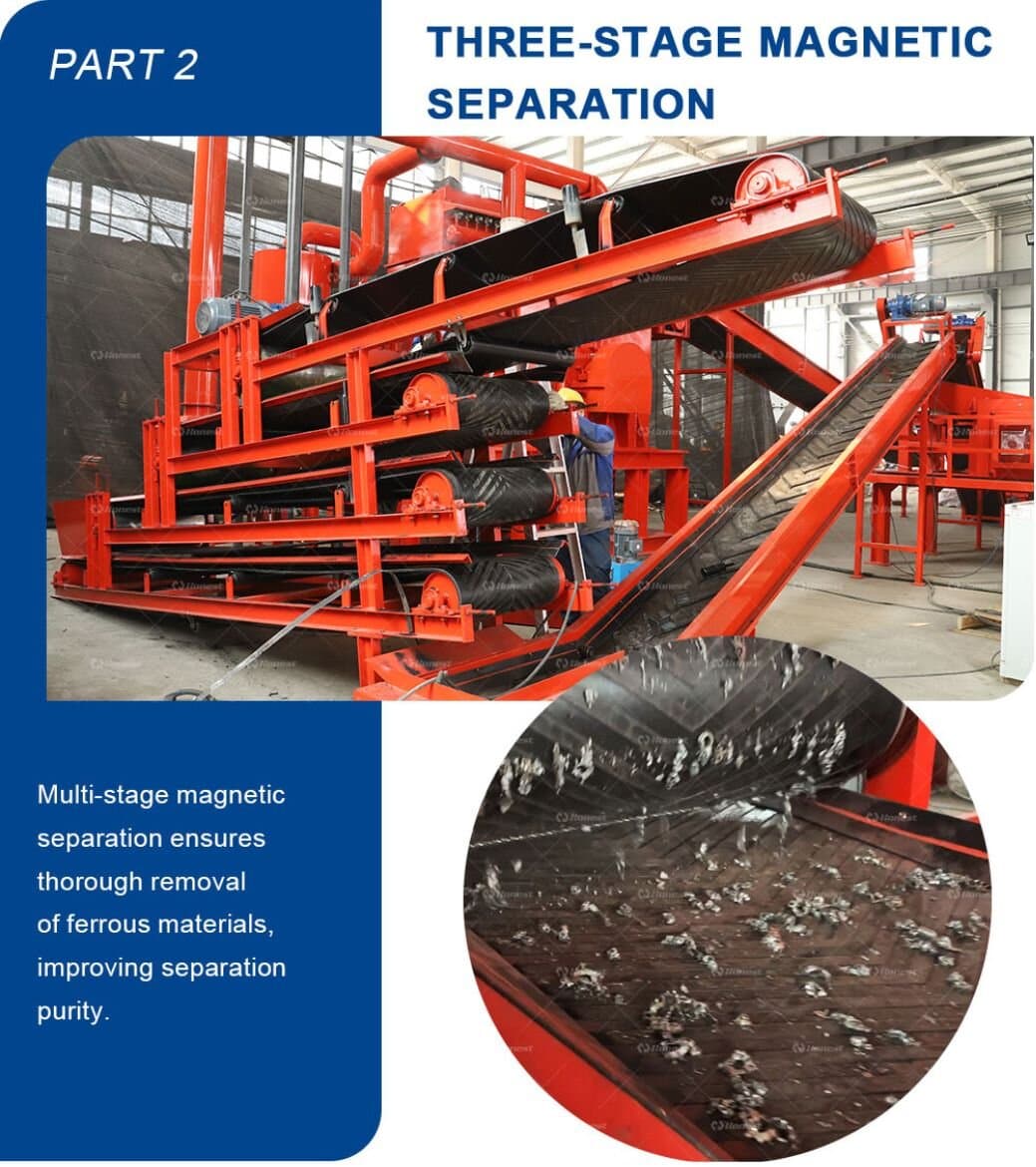

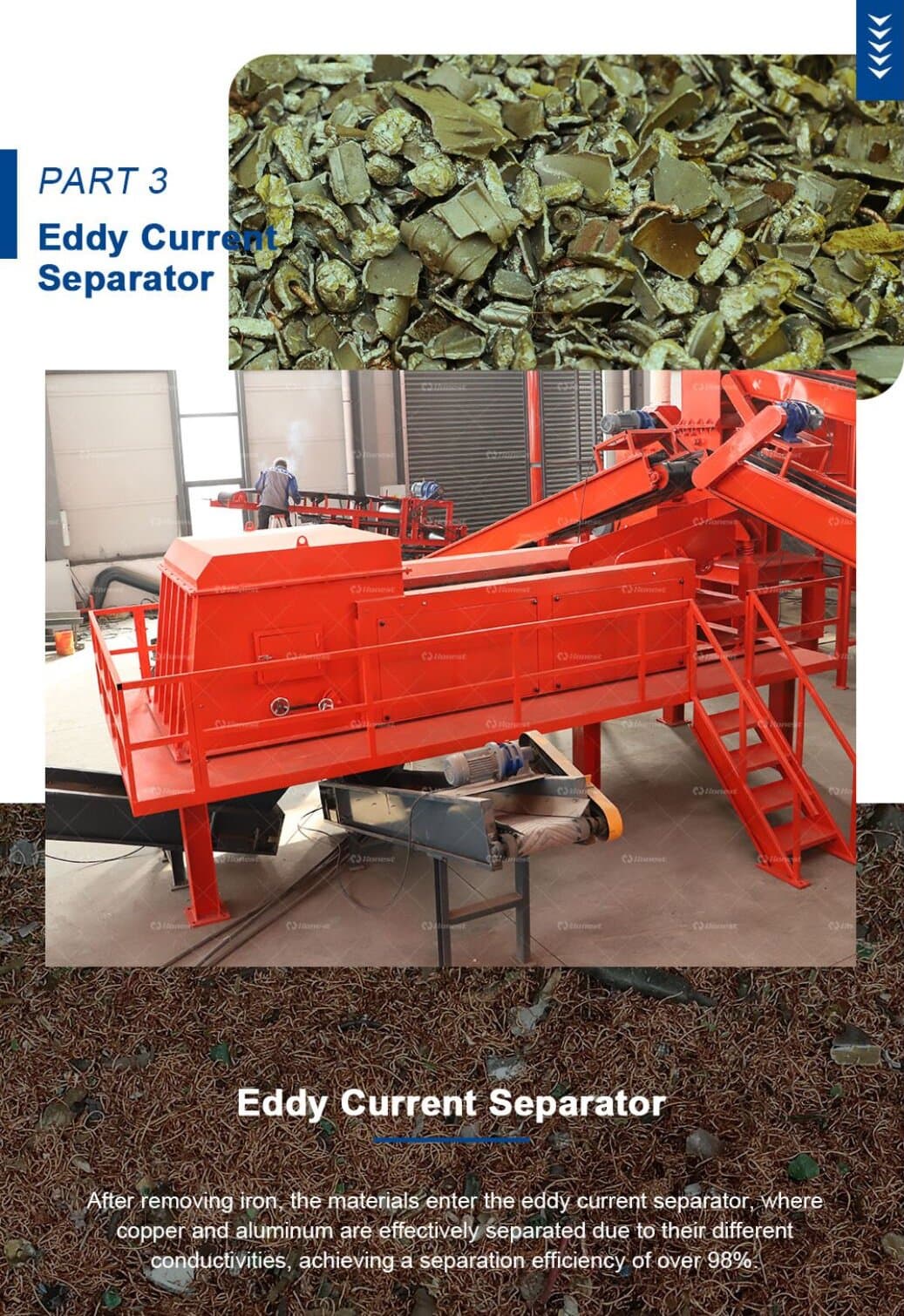

Scrap metal motor stator rotor recycling machine mainly includes hammer crusher, knife crusher, magnetic separator, wind separator, pulse dust collector and other auxiliary machines. The knife crusher carries out preliminary crushing of materials. The hammer crusher further crushes the materials. The wind conveying system utilizes wind power to convey the materials. The belt magnetic separator separates the magnetic material. Roller magnetic separator separates the magnetic material again. Vibrating screen screens the materials with different particle sizes. Screw conveyor conveys the materials. There are two airflow sorting machines, which separate materials by airflow. Pulse dust collector (including cyclone dust collector) collects dust. The electric control cabinet controls the operation of the equipment. Belt conveyor (some contain magnetic rollers) conveys materials. Magnetic separator consists of two drum separators to ensure the separation rate up to 98%; air separator makes the copper cleaner and more pure. Pulse dust collector efficiently and well removes the dust in the production process, keeping the workshop clean and free from secondary pollution.

Scrap Motor Stator Recycling Plant Brief Introduction

Equipment Composition: Including Hammer Crusher, Knife Crusher, Magnetic Separator, Air Separator, Pulse Dust Collector And Other Auxiliary Machines

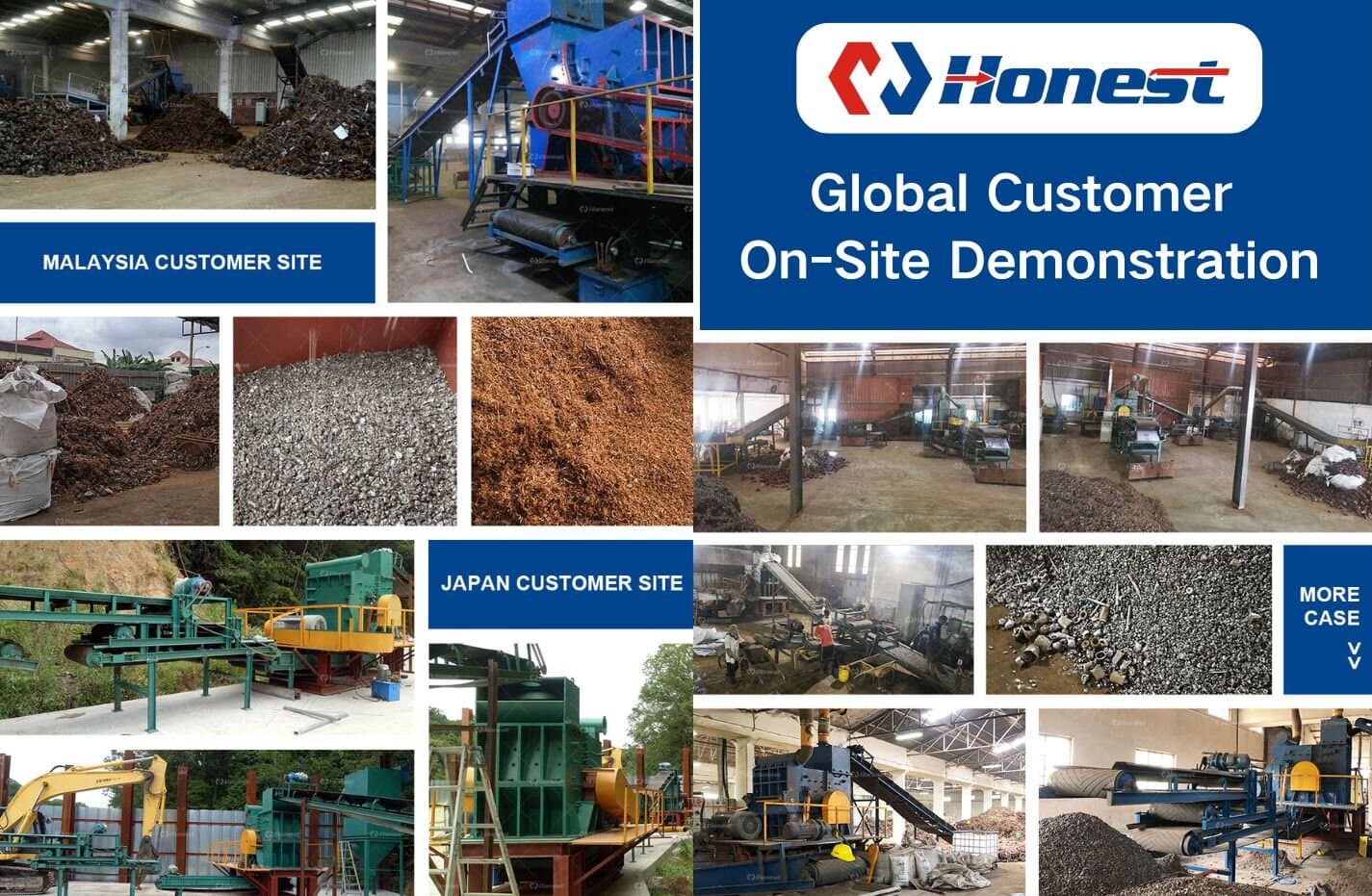

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export