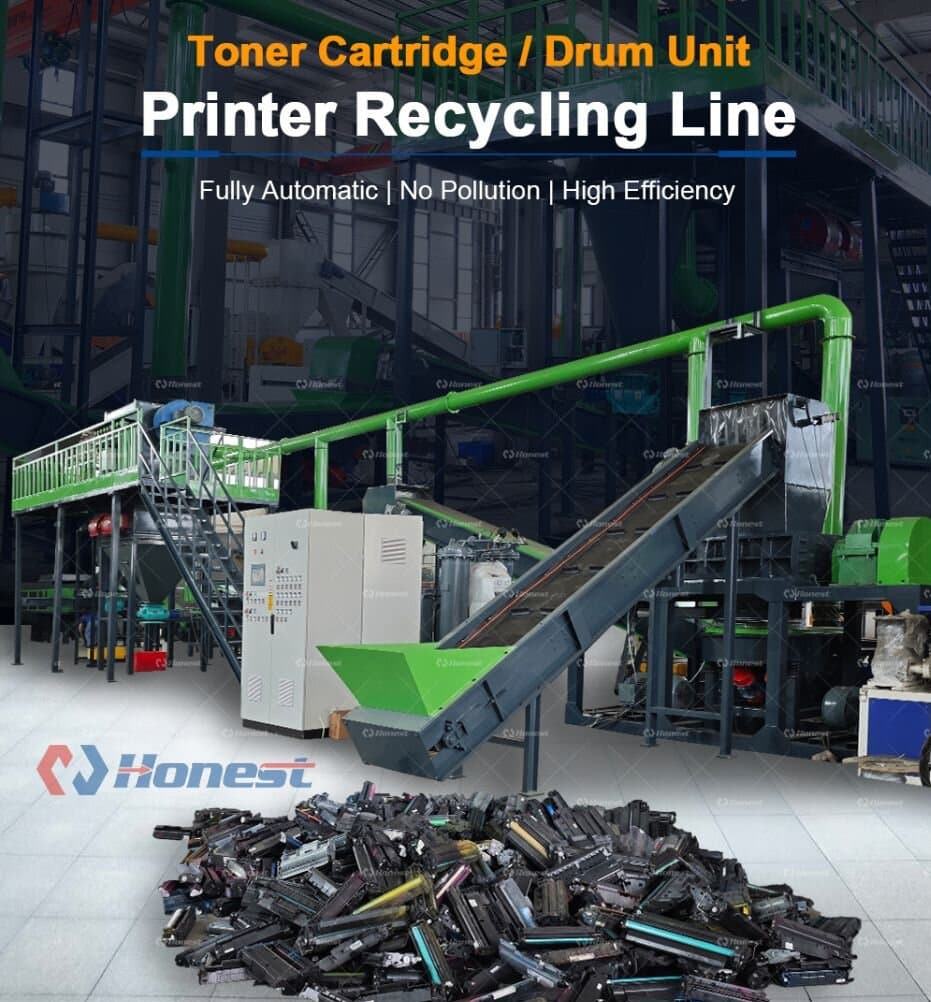

Equipment Features

Main Applications:Recycling of toner cartridges and drum units.

Raw Materials:toner cartridges,drum units,ink cartridge.

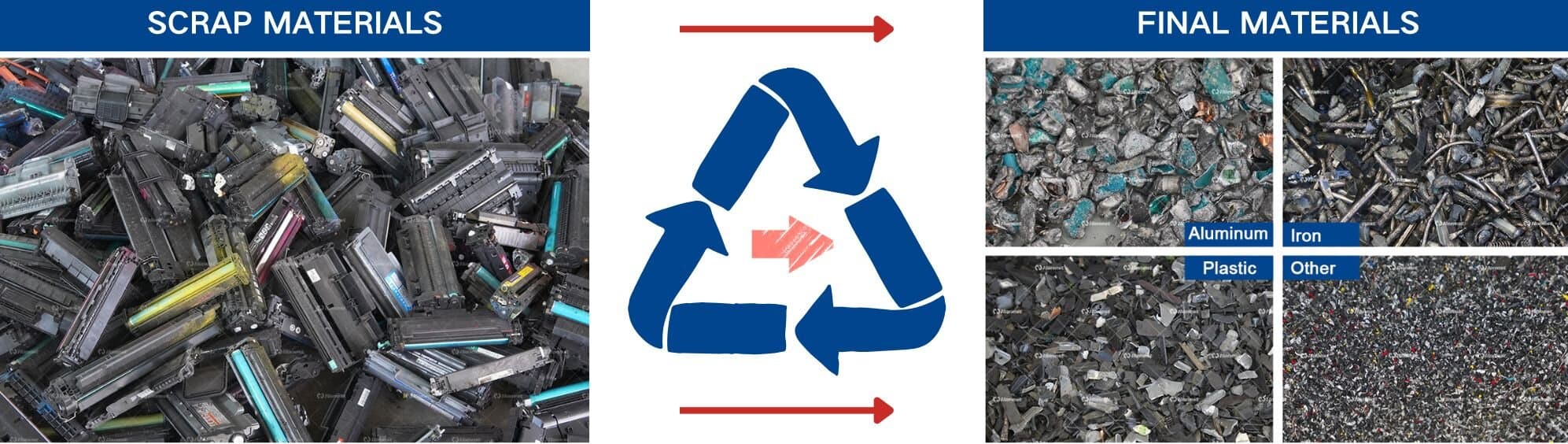

Main Final Products:Aluminum, plastic, iron, toner residues, other.

If you want to start your recycling business, feel free to contact us.

Our fully automatic toner cartridge and drum unit recycling line provides a complete solution for safely processing waste cartridges, printer parts, and related electronic consumables. Designed with advanced automation and safety systems, it achieves efficient material recovery while eliminating pollution risks.

Toner Cartridge Recycling Machine Product Usage / Application:

The toner cartridge recycling machine is used for processing waste toner and ink cartridges, drum units, and other printer consumables. It efficiently recovers plastics, steel, aluminum, copper, and toner powder through shredding, crushing, screening, and separation, making it ideal for recycling enterprises, printer consumable manufacturers, and waste management companies. Beyond cartridges, the system can also handle printers, copiers, and fax machines, ensuring safe disposal of hazardous components while turning e-waste into valuable raw materials (Aluminum, plastic, iron, toner residues, other).

Technical Parameters

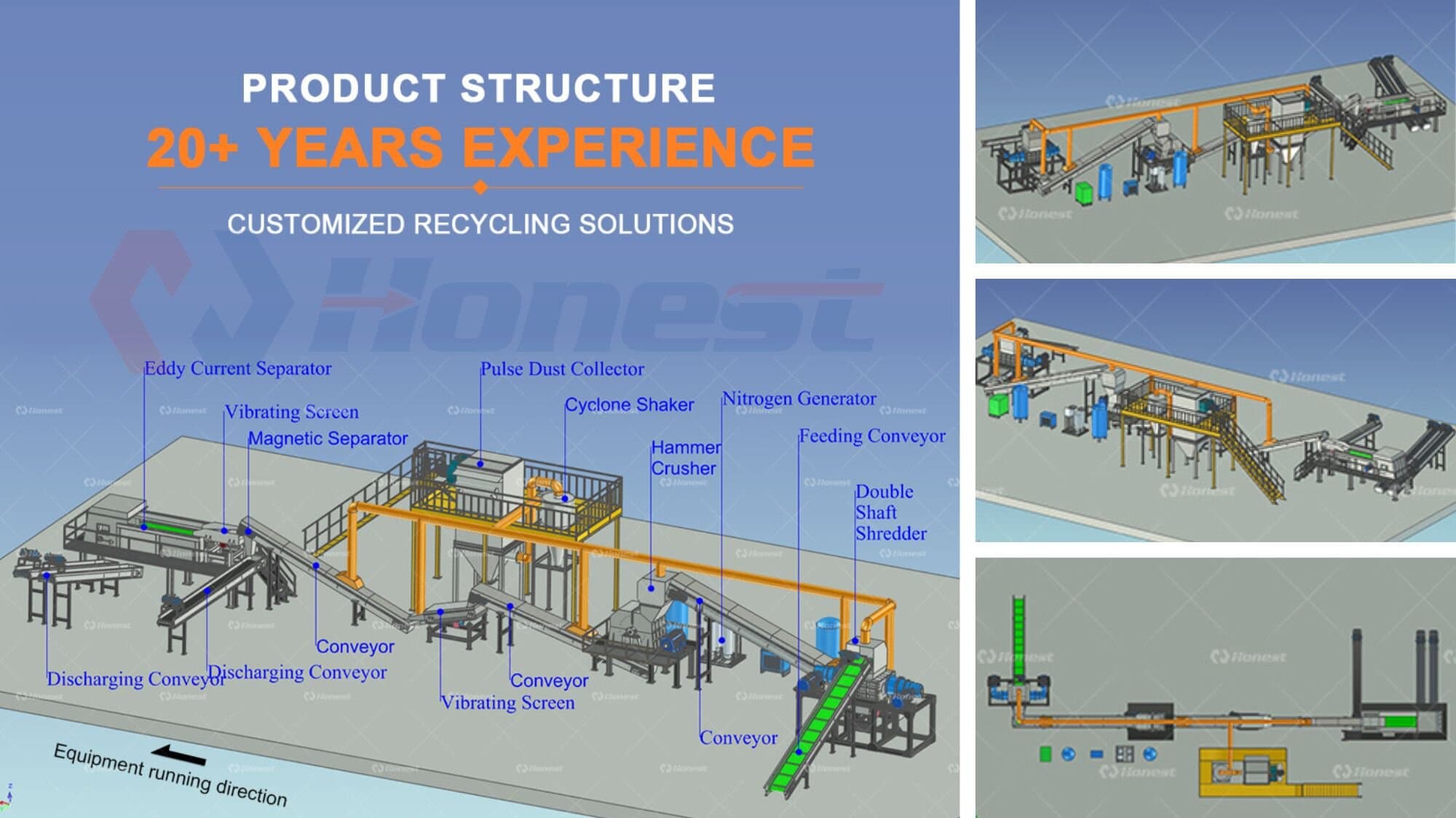

| Name | Power | Size |

| Double Shaft Shredder | 18.5KW*2 | 3500*1450*3040 |

| Vibrating screen | 0.37KW | 2150*650 |

| Hammer Crusher | 45KW | 2800*2050*3150 |

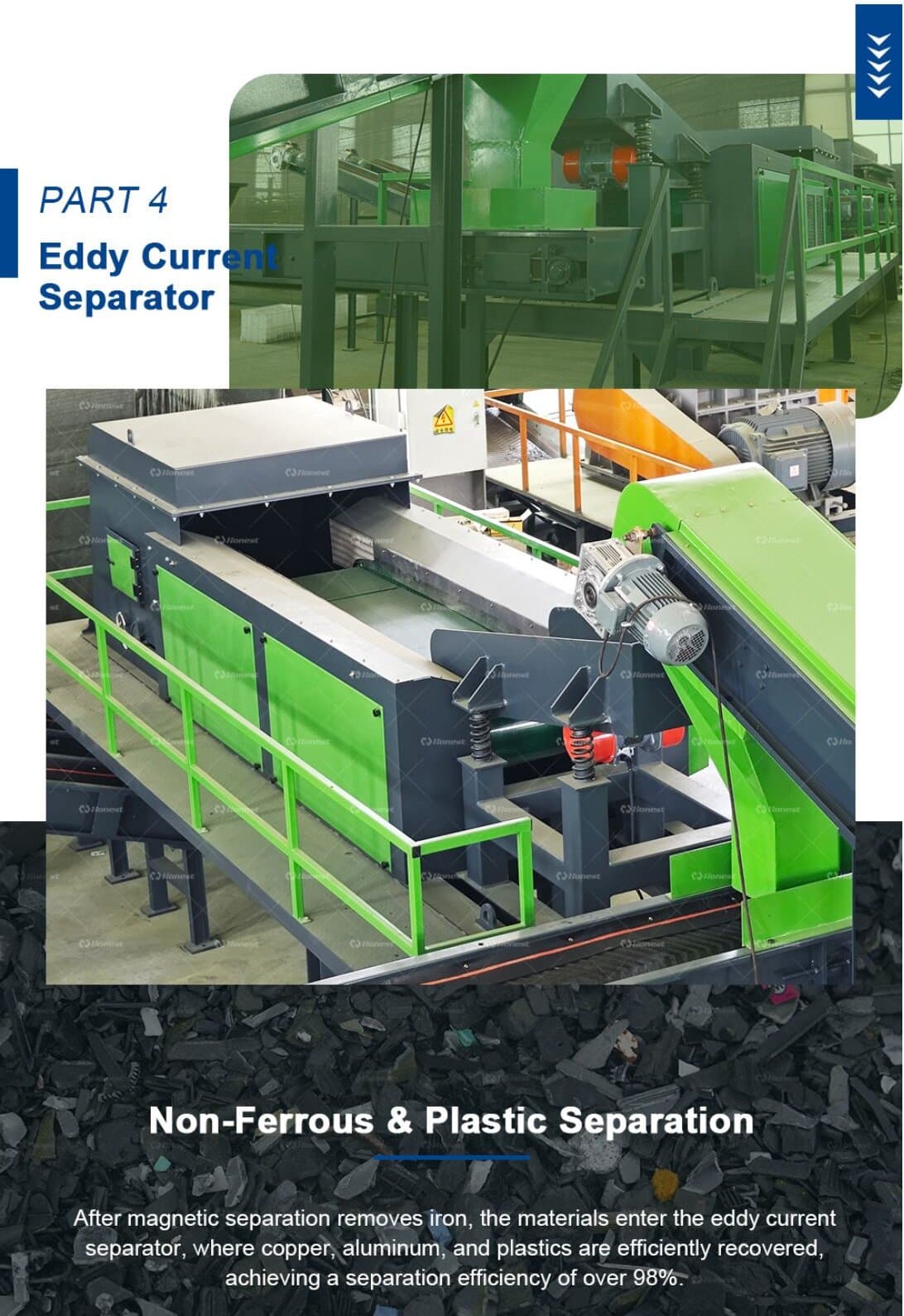

| Eddy Current Separator | 7.95KW | 5300*1930*2300 |

| Pulse Dust Collector | 15KW | 1600*1500*4500 |

| Cyclone Shaker | 1150*1100*3845 | |

| Toner Cartridge Recycling Machine Capacity | 500-1000 kg/h | |

Product Structure Toner Cartridge Recycling Machine

The process begins with a double-shaft shredder that pre-shreds materials into manageable sizes. Equipped with temperature sensors and a nitrogen injection system, the shredder prevents overheating and fire hazards by automatically closing inlet and outlet valves and creating an inert atmosphere. Materials then pass through a hammer crusher for secondary reduction to 2–3 cm, ensuring optimal separation efficiency.

After crushing, a vibrating screen collects fine toner powder while larger particles move forward. Magnetic separation effectively removes ferrous metals such as iron, followed by eddy current separation that recovers aluminum, copper, and plastics with a separation efficiency of over 98%. Throughout the process, Schneider electrical components and PLC control guarantee stable operation.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export