Equipment Features

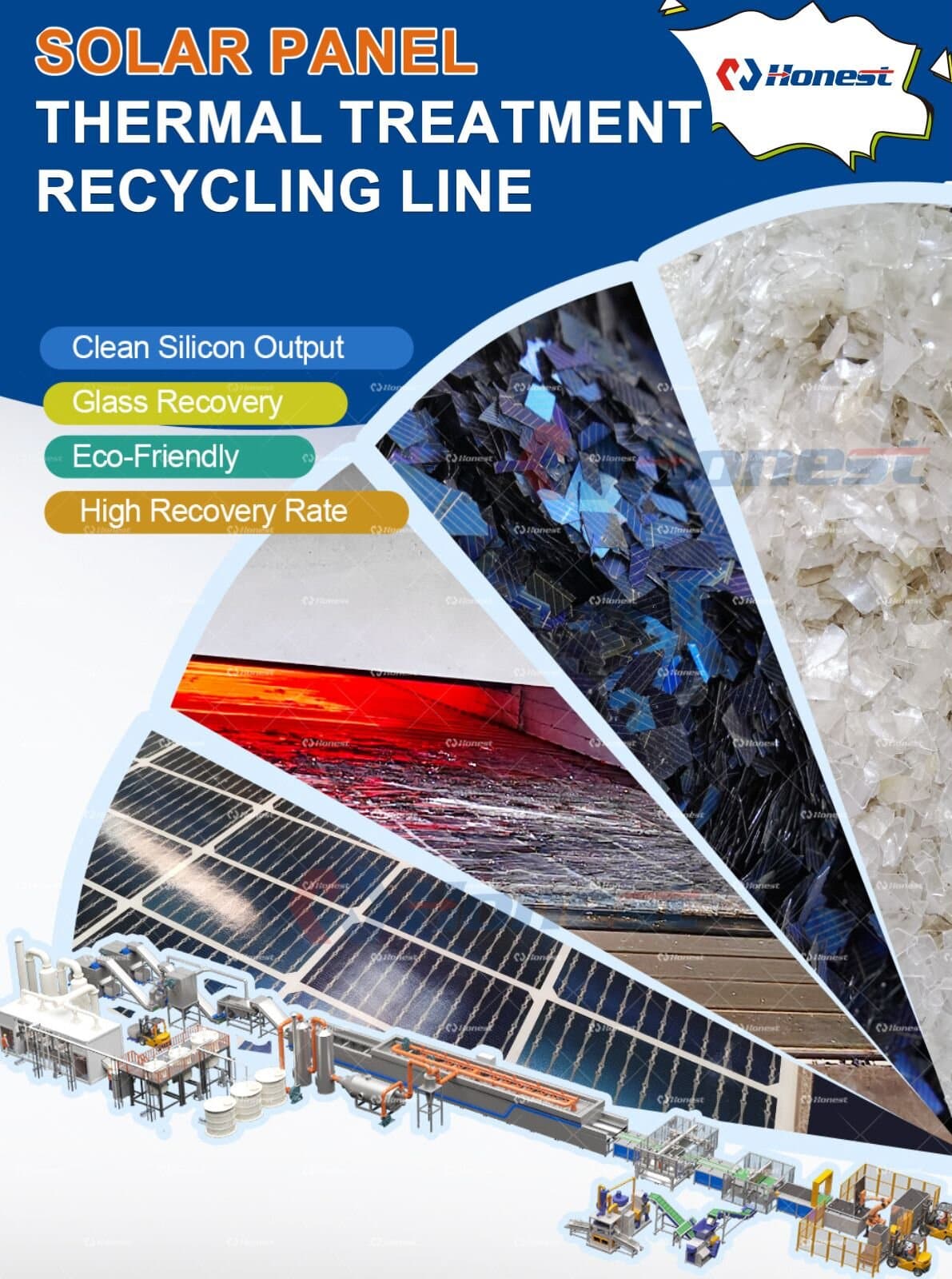

Main Applications:Pyrolysis recycling of end-of-life photovoltaic panels

Raw Materials:Single-glass and double-glass crystalline silicon photovoltaic modules

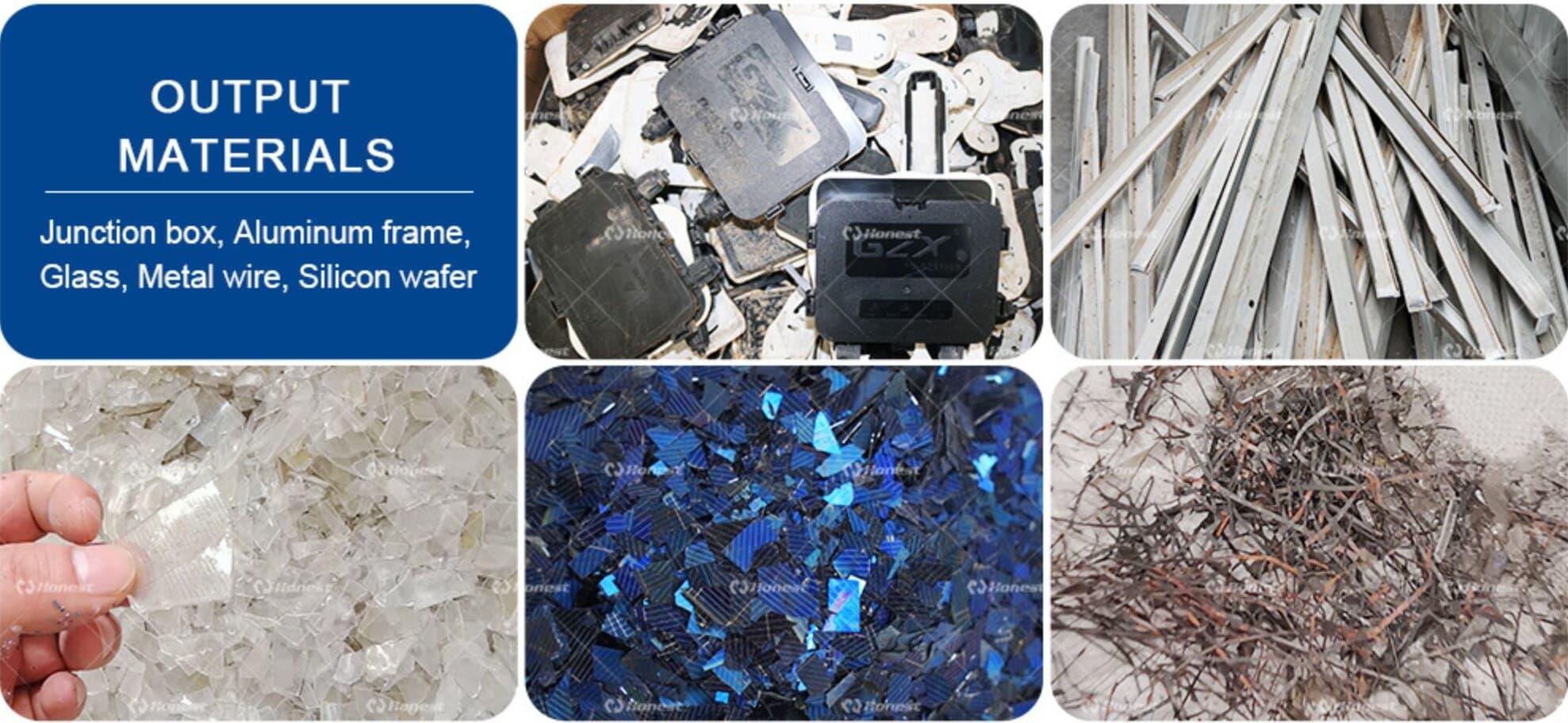

Main Final Products:Junction Boxes, Aluminum Frames,Glass, Solder Ribbons (Metal Wires), Silicon Wafer

If you want to start your recycling business, feel free to contact us.

The Solar Panel Thermal Treatment Recycling Line, also known as Photovoltaic Panel Pyrolysis Recycling Equipment, is an automated and environmentally friendly recycling solution designed to extract silicon from end-of-life solar panels. The system integrates robotic feeding, intelligent dismantling, patented pyrolysis technology, multi-stage separation, and classified material collection into a stable, continuous, and scalable recycling process. It enables clean silicon output, high-rate glass recovery, and overall high material recovery while minimizing environmental impact. With a high level of automation and reliable operation, the recycling line is suitable for large-scale, continuous processing of photovoltaic modules of various sizes and generations, making it ideal for decommissioned solar farms, third-party recycling facilities, and renewable energy waste management projects.

Solar Panel Pyrolysis Line Product Usage

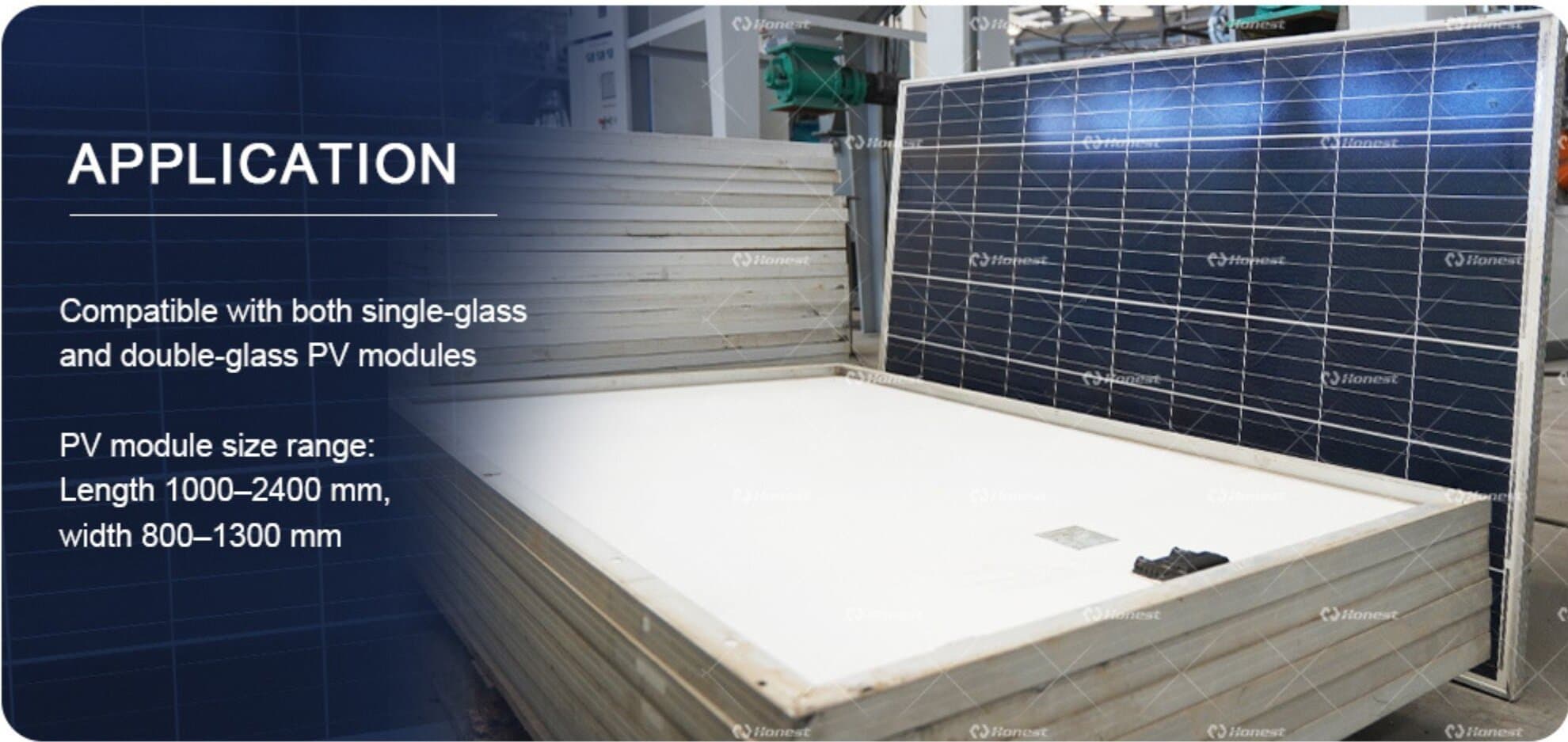

The recycling line is designed to process both single-glass and double-glass crystalline silicon photovoltaicmodules, meeting the demands of industrial and continuous recycling operations. The system is compatible with various module structures, offering strong adaptability. It supports PV modules with dimensions ranging from 1000 to 2400 mm in length and 800 to 1300 mm in width, covering most mainstream and end-of-life PV module specifications.

Automated Solar PV Panel Pyrolysis Recycling Machine Output Materials

The recycling line is designed to process both single-glass and double-glass crystalline silicon photovoltaicmodules, meeting the demands of industrial and continuous recycling operations. The system is compatible with various module structures, offering strong adaptability. It supports PV modules with dimensions ranging from 1000 to 2400 mm in length and 800 to 1300 mm in width, covering most mainstream and end-of-life PV module specifications.

Technical Parameters

| Model | HN-PVR-F60 |

| Motor Power | 240KW |

| Capacity | 50-60 PCS/H |

| Dimension L/W/H(m) | 108*11*5.5 |

Solar PV Panel Recycling Workflow

PART 01. ROBOTIC FEEDING SYSTEM

First, industrial robots are used to automatically pick and feed discarded photovoltaic modules.

PART 02. JUNCTION BOXREMOVAL

An optical sensing andvision recognition system accurately locates and automatically removes junction boxes.

PART 03. FRAME REMOVAL

A fully automatic frame removal system efficiently detaches aluminum frames from PV modules of various sizes and specifications.

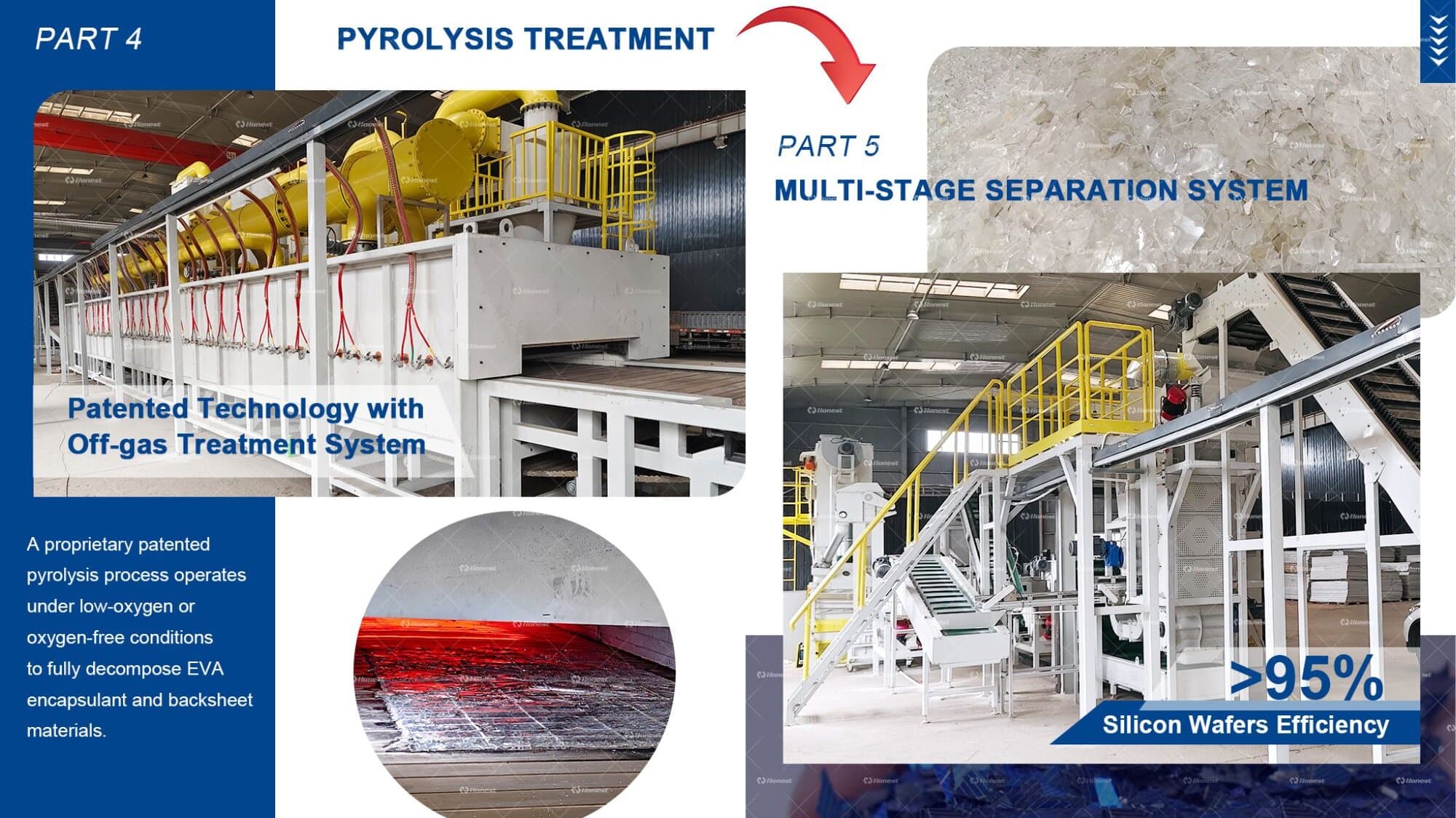

PART 04. PYROLYSIS TREATMENT — Patented Technology with Off-gas Treatment System

A proprietary patented pyrolysis process operates under low-oxygen oroxygen-free conditions to fully decompose EVA encapsulant and backsheet materials.

PART 05. MULTI-STAGE SEPARATION SYSTEM

Multiple physical separation technologies ensure precise material separation. Screening systems classify materials by particle size, achieving stable operation with silicon wafer and glass recovery rates exceeding 95%, significantly improving overall recovery efficiency and economic value.

We are a professional manufacturer of recycling machinery and equipment, offering advanced technology and attentive service to provide the most suitable solutions for your needs. Every machine and production line undergoes strict quality control, including trial runs with raw materials, ensuring stable performance and compliance with customer requirements—whether for a single machine or a complete system. Our Photovoltaic Pyrolysis Recycling Line is an environmentally friendly, highly automated solution designed for stable, large-scale, continuous processing of PV modules of various sizes and generations, making it ideal for decommissioned solar farms, third-party recycling centers, and renewable energy waste management projects. For more information or to schedule a factory visit—either in-person or virtual—please contact our sales team.

Solar Panel Thermal Treatment Recycling System

The Solar Panel Thermal Treatment Recycling System processes end-of-life photovoltaic modules through a fully automated workflow, starting with robotic feeding, followed by intelligent junction box and aluminum frame removal. The core patented pyrolysis treatment decomposes EVA and backsheet materials under low-oxygen or oxygen-free conditions, enabling effective liberation of internal components. Subsequent multi-stage physical separation accurately sorts silicon wafers, glass, metals, and other materials into independent output streams, achieving high recovery efficiency and stable, continuous operation for large-scale PV recycling.

Solar PV Panels Thermal Treatment Recycling Line Sales Areas

Solar PV Panels Thermal Treatment Recycling Line Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export