Equipment Features

Main Applications:Used for recycling scrap metal from vehicles, appliances, and industrial waste.

Raw Materials:Processes steel, iron, copper, aluminum, stainless steel, cables, and motors.

Main Final Products:Outputs clean iron, copper, aluminum, and non-metallic materials.

If you want to start your recycling business, feel free to contact us.

We Waste Steel Tailings Scraps Metal Recycling and Sorting Line a comprehensive recycling line designed for the efficient crushing, separation, and recovery of ferrous metals, non-ferrous metals, and non-metallic materials. The system is customizable to meet your specific materials and recycling goals.

Scrap Metal Shredding Crushing Sorting Line Product Usage / Application:

This Scrap Metal Shredding Crushing Sorting Line is suitable for processing a wide variety of scrap metal materials:

Scrap Vehicles & Appliances : Car bodies, tinplate, household appliances, bicycles, truck parts, cans, and steel structures (≤6mm thick).

Scrap Steel & lron : Scrap steel tailings,mixed scrap iron/steel, shavings, old drums, color steel tiles, thin metal sheets, and construction scraps.

Copper Scrap : Brass, red copper, copper sheets/shavings, and copper-containing components like cables, motorstransformers,and panels 87%.

Aluminum Scrap : Aluminum sheets, wires, ingots, alloy doors/windows, and aluminum-containing machinery ,Stainless Steel Scrap Offcuts, sheets, utensils, and decorative or structural stainless steel waste.

Non-Ferrous & Precious Metals : Lead, zinc, tin, molybdenum, solder, rare and precious metals, and other valuable raw materials.

Through processes such as crushing and separation, these materials can be effectively sorted into iron.copper, aluminum, and non-metallic components, significantly improving recycling efficiency and resource utilization.

Below are some examples of the output materials.

Technical Parameters

| Equipment Name | Power |

| 2000 Double Shaft Shredder (Soft Start + H13 Blade) | 132 kW + 132 kW = 264 kW |

| 630 Hammer Crusher (Water Cooling, Vibration Pad) | 630 kW |

| Vibrating Screen | 2.2 kW |

| Rotary Screen (Dust Removing) | 22 kW |

| Vibrating Screen | 2.2 kW |

| Drum Magnetic Separator 100% | 3 kW |

| Rotary Screen | 22 kW |

| Eddy Current Separator | 5 kW × 3 = 15 kW |

| Pulse Dust Collector (Spark Arrester & Cyclone) | 30 kW |

| Total Power: 1072 kW | |

| Footprint: 80 m × 24 m × 6 m | |

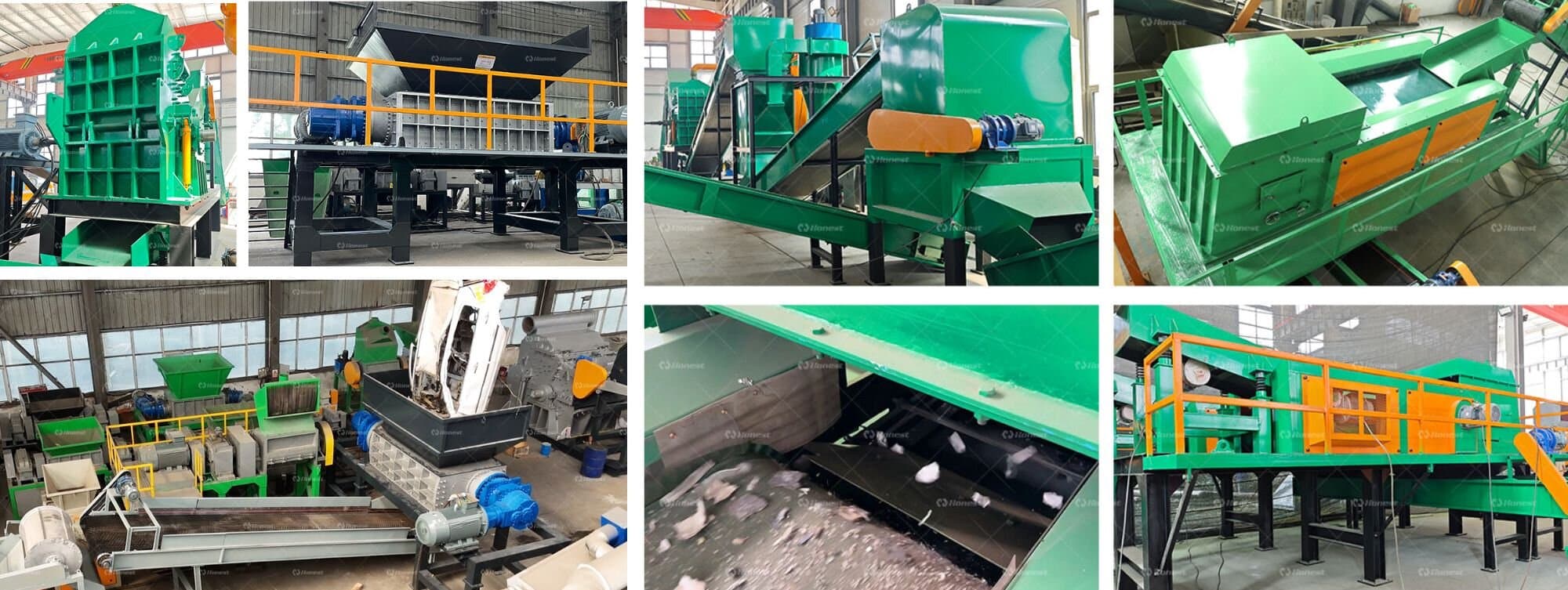

Product Structure Scrap Metal Shredding Crushing Sorting Line

Material Feeding : The raw materials are loaded onto a chain-type conveyor, which transports them steadily into the shredder.

Primary Shredding : The shredder breaks the materials into large pieces, making them suitable for further processing.

Secondary Crushing : The shredded materials are then transferred via conveyor to a hammer crusher.where they are crushed into smaller. uniform particles.

Dust Collection : A dust collection system operates simultaneously to capture dust generated during the crushing process, ensuring a clean and environmentally friendly operation.

Magnetic Separation : The crushed material passes through a magnetic separator, which removes ferrous metals (iron) from the material stream.

Rotary screen : The remaining non-ferrous and plastic mixture is conveyed into a rotary screen, which separates the material into three different size categories, each discharged from a separate outlet.

Eddy Current Separation : Each of the three size-based outputs is fed into a dedicated eddy current separator, which effectively separates non-ferrous metals (like aluminum and copper) from plastic.

Key components of Scrap Metal Shredding Crushing Sorting Line

DOUBLE SHAFT SHREDDER : Shred the materials into big pieces. Capacity:12-15 tons of metal per hour.

METAL CRUSHER : The hammer crusher uses a high-speed rotating hammer head to crush materials into smaller pieces through impact force.

ZIGZAG SEPARATOR : Zigzag Separator is a separator for light and heavy materials based on their aerodynamic properties.

MAGNETIC SEPARATOR : The materials are screened by the vibrating screen, during which the magnetic roller separates the iron-containing materials.

ROTARY SCREEN : Based on material size, plastic and non-ferrous materials are separated into three size categories.

EDDY CURRENT SEPARATOR : Materials of similar size enter the eddy current separator to separate plastics and non-ferrous metals such as copper and aluminum.

We follow a strict quality control system to ensure each machine performs at its best. Whether it’s a single unit or a complete production line, every machine is thoroughly tested before leaving the factory. We even purchase raw materials to conduct trial runs, ensuring that every component meets our production standards and delivers reliable performance.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export