Equipment Features

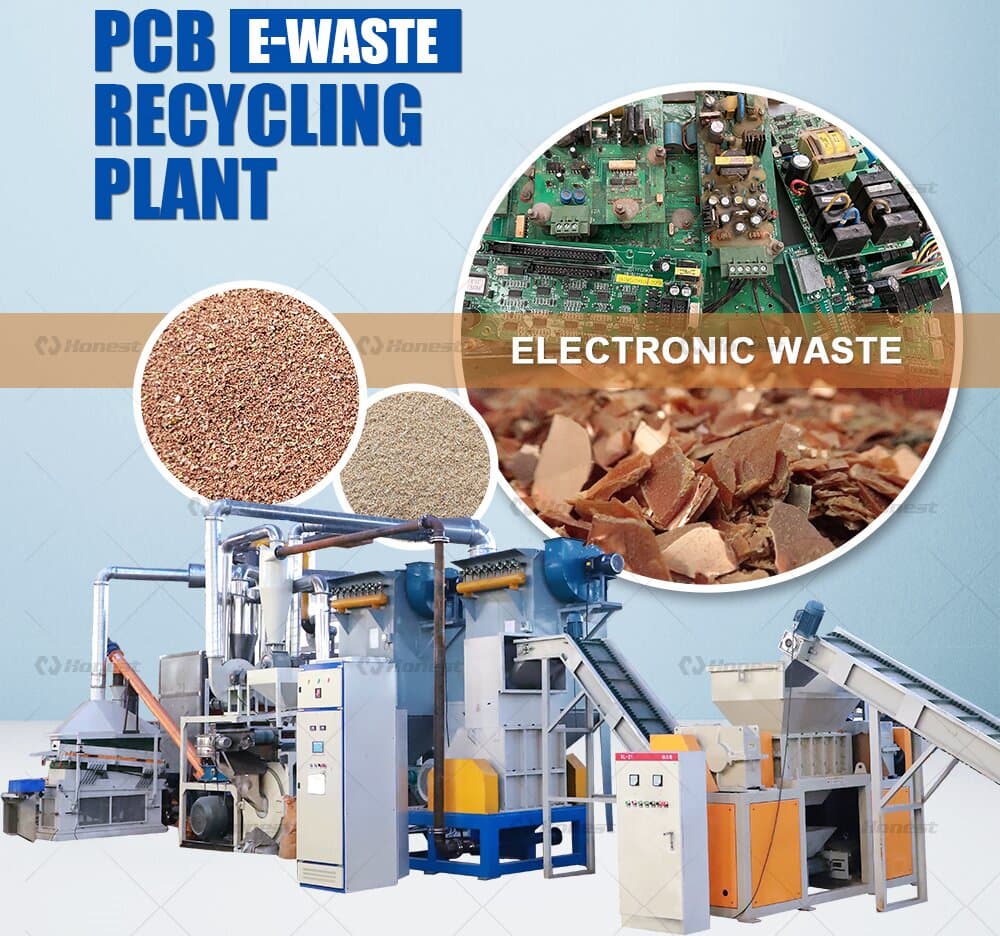

Main Applications:Recovering valuable metal and non-metal materials from Electronic Waste

Raw Materials:Such as computer motherboards, cell phone circuit boards, circuit boards from household appliances, copper-clad boards, and other electronic waste.

Main Final Products:Copper,Resin Powder,Mixed Metal,Gold,Ag,Pt,Pd

If you want to start your recycling business, feel free to contact us.

This Electronic Waste Recycling Plant(waste circuit board recycling line) is used to process materials such as waste circuit boards, copper-clad laminates, circuit board scrap, etc. It realizes the separation of metal and non-metal, and recovers mixed metal and resin powder. The end products are resin powder and some copper powder. As metal, fiber and resin have high value, this production line can not only turn waste into treasure, but also bring great economic benefits. After years of practice and theoretical analysis, the plant obtains the best separation effect, and the separation purity can reach 99%.

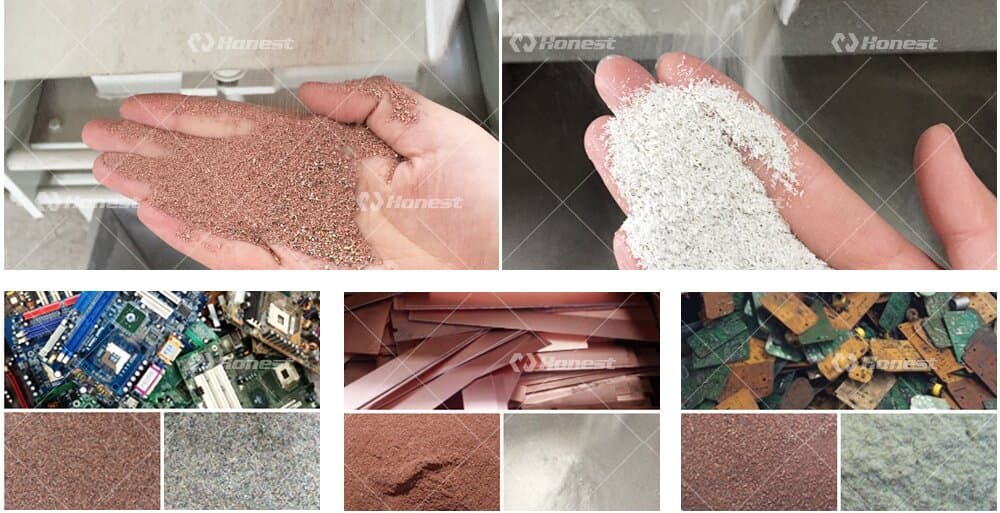

Raw Material

Circuit board recycling equipment is suitable for raw materials such as computer motherboards, mobile phone circuit boards, circuit boards from household appliances and other electronic devices,copper-clad laminates, and circuit board scraps.

Final Products

This integrated electronic waste recycling plant effectively recovers precious metals like Copper,Resin Powder,Mixed Metal,Gold,Ag,Pt,Pd from electronic waste.

Technical Parameters

| Model | Capacity | Power | Weight | Machine Size |

| HN-PCB-150 | 100-150kg/h | 65kw | 7500kg | 12m*6m*5m |

| HN-PCB-300 | 200-300kg/h | 102kw | 15000kg | 20m*5m*5m |

| HN-PCB-500 | 400-500kg/h | 124kw | 20000kg | 25m*6m*5m |

| HN-PCB-1000 | 800-1000kg/h | 238kw | 40000kg | 35m*8m*5m |

E-Waste Recycling Plant Brief Introduction

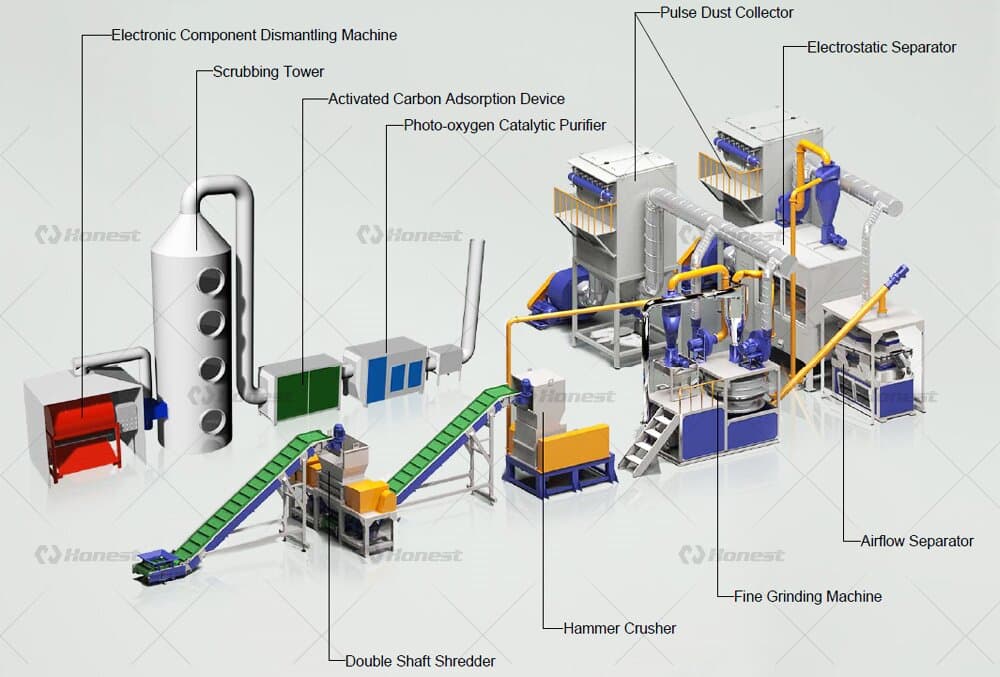

Electronic Component Dismantling Machine: used to dismantle electronic components on circuit boards.

Scrubbing Tower: may be used for cleaning and purification of waste gas or liquid generated in the treatment process.

Activated Carbon Adsorption Device: utilizes activated carbon to adsorb harmful substances in the exhaust gas.

Photo-oxygen Catalytic Purifier : Further purification of exhaust gases through photo-oxygen catalytic reaction.

Double Shaft Shredder: Preliminary crushing of circuit boards.

Hammer Crusher: further crushing of materials.

Fine Grinding Machine: Grinds the material to a finer size for sorting.

Airflow Separator: Separate materials according to their different movement characteristics in the airflow.

Electrostatic Separator: Separates metallic and non-metallic substances.

Pulse Dust Collector: Collects dust generated during the production process.

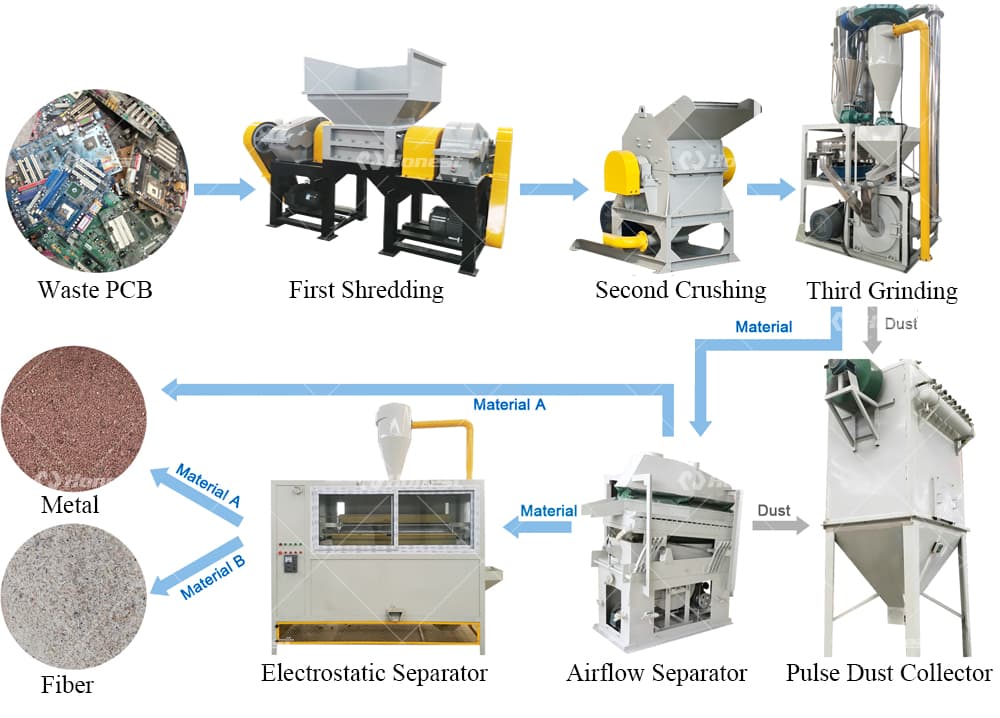

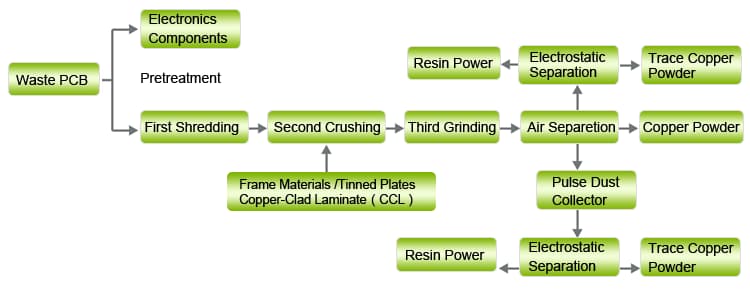

Electronic Waste Recycling Equipment Workflow

The recycling equipment adopts a three-stage crushing process: firstly, a double-shaft shredder is used for initial crushing, then a hammer crusher is used for secondary crushing, and finally a high-speed turbine mill is used for fine grinding. The finely ground materials are separated by airflow separator and electrostatic separator. The equipment has the advantages of unique structure, large output and energy saving. Multiple machines work in concert, and the material is automatically run after single loading, controlled by PLC. The machine excels in copper recovery and is equipped with devices to prevent secondary pollution, with a copper recovery rate of up to 99%, a leading position in the world.

Scrap circuit boards are ground into a mixture of metal and resin fibers and then separated by pneumatic and electrostatic separation. The end of the pneumatic separation process is equipped with an electrostatic separator, which effectively solves the problem of dust pollution.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export