Equipment Features

Main Applications:Separate the different kinds of plastic materials

Raw Materials:ABS/HIPS, PP, PE, PET/PC/PMMA, PP/PE, PA/PC mixed materials

Main Final Products:Pure Plastic

If you want to start your recycling business, feel free to contact us.

Our Plastic Sorting and Recycling Plant is an advanced system designed to efficiently process mixed plastic waste. Using cutting-edge technologies such as optical sorting, near-infrared (NIR) identification, and density separation, the plant categorizes and separates different plastic resin types (e.g., PET, HDPE, PP). After sorting, the plastics undergo shredding, washing, and granulation processes, resulting in high-quality recycled plastic flakes or pellets, ready for reuse in manufacturing.

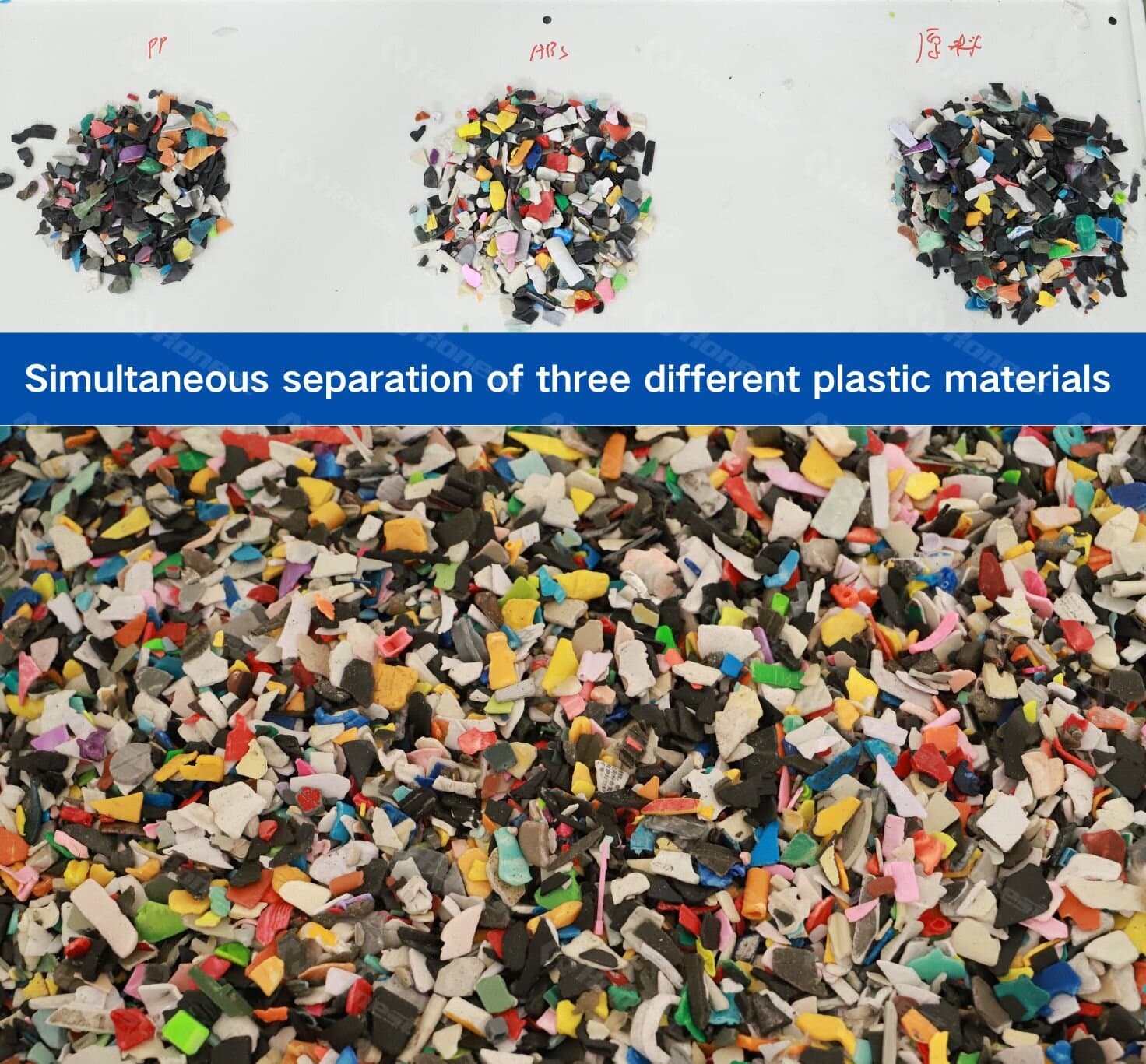

Raw Material

The plastic separator is a special design to separating the plastics, it can beseparate three different kinds of plastic materials at once time. Such asABS/HIPS,PP/PE,PET/PC/PMMA,PVC/PET,PA/PC mixed materials, theaccuracy can be up to morethan 98%.

Final Products

It mainly uses to separate different kinds of mixed plastic, such as: PP, PE, PVC, PET, ABS and so on.

Technical Parameters

| Model | HN-PR-500 | HN-PR-1000 |

| Power | 30KW/380V | 55KW/380V |

| Capacity | 500 KG/H | 1000 KG/H |

| Static pressure | 8-10KV | 18-20KV |

| Dimension | 4.2×3.6×4.2M | 8.2×7.0x4.2M |

| Weight | 3.8T | 7.5T |

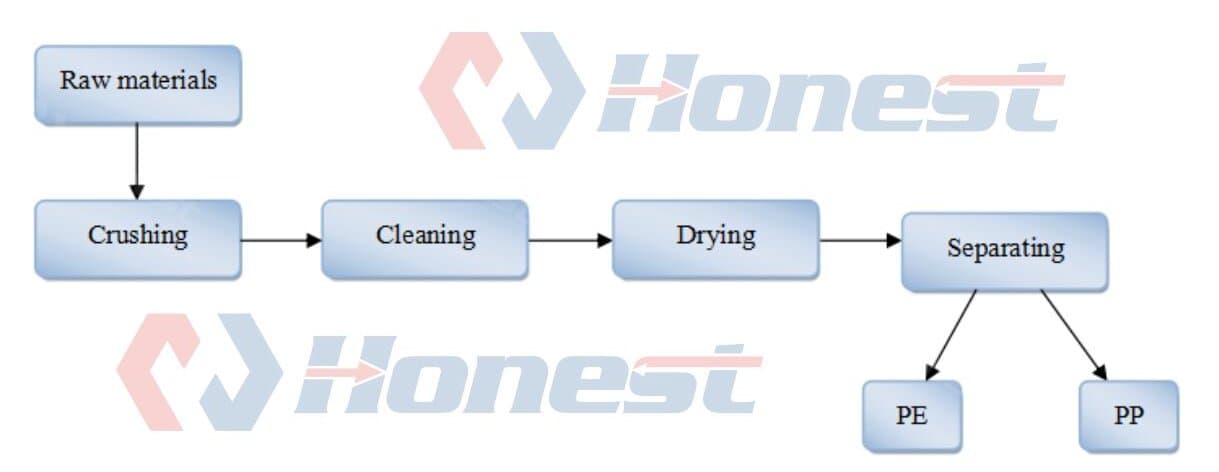

Plastic Sorting and Recycling Equipment Workflow

The Plastic Sorting and Recycling Plant utilizes advanced technology to efficiently process mixed plastic waste. Plastics are crushed and cleaned, dried in a dryer, and then transferred to an electrostatic generator for electrification. Since each plastic type has different electrical properties, the plastic separator efficiently separates the materials. The key component of the plant is a plastic separator designed to separate three different types of plastic materials simultaneously with an accuracy rate of over 98%. The separator can handle mixed materials such as ABS/HIPS, PP/PE, PET/PC/PMMA, PVC/PET and PA/PC.

The equipment layout can be customized according to the customer’s factory size and structure to ensure optimal equipment placement. The factory adopts PLC control, simple operation and maintenance, high efficiency, high separation ratio and large capacity. The system adopts primary gravity separation and secondary air flow separation, with a separation rate of up to 99%. The pulse dust collector effectively removes dust during the production process, keeps the workshop environment clean and prevents secondary pollution.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export