Equipment Features

Main Applications:Processing and recycling of used lithium-ion batteries

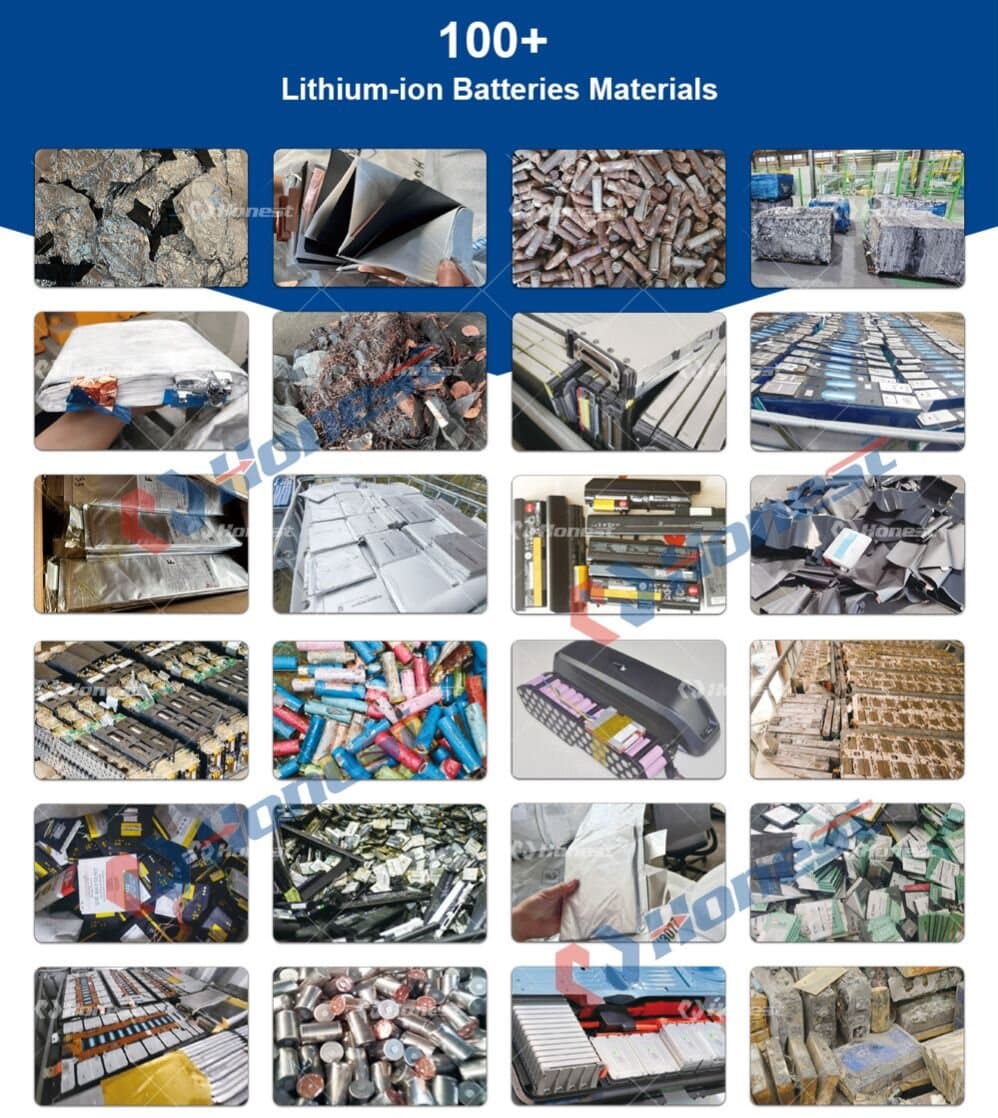

Raw Materials:Waste cylindrical batteries, square batteries, soft pack batteries, cell phone batteries, shell batteries, negative plates, positive plates and many other types of lithium-ion batteries.

Main Final Products:Black Mass, Aluminum Granules, Copper Granules, Plastic, Steel Shell and Separator Plastic

If you want to start your recycling business, feel free to contact us.

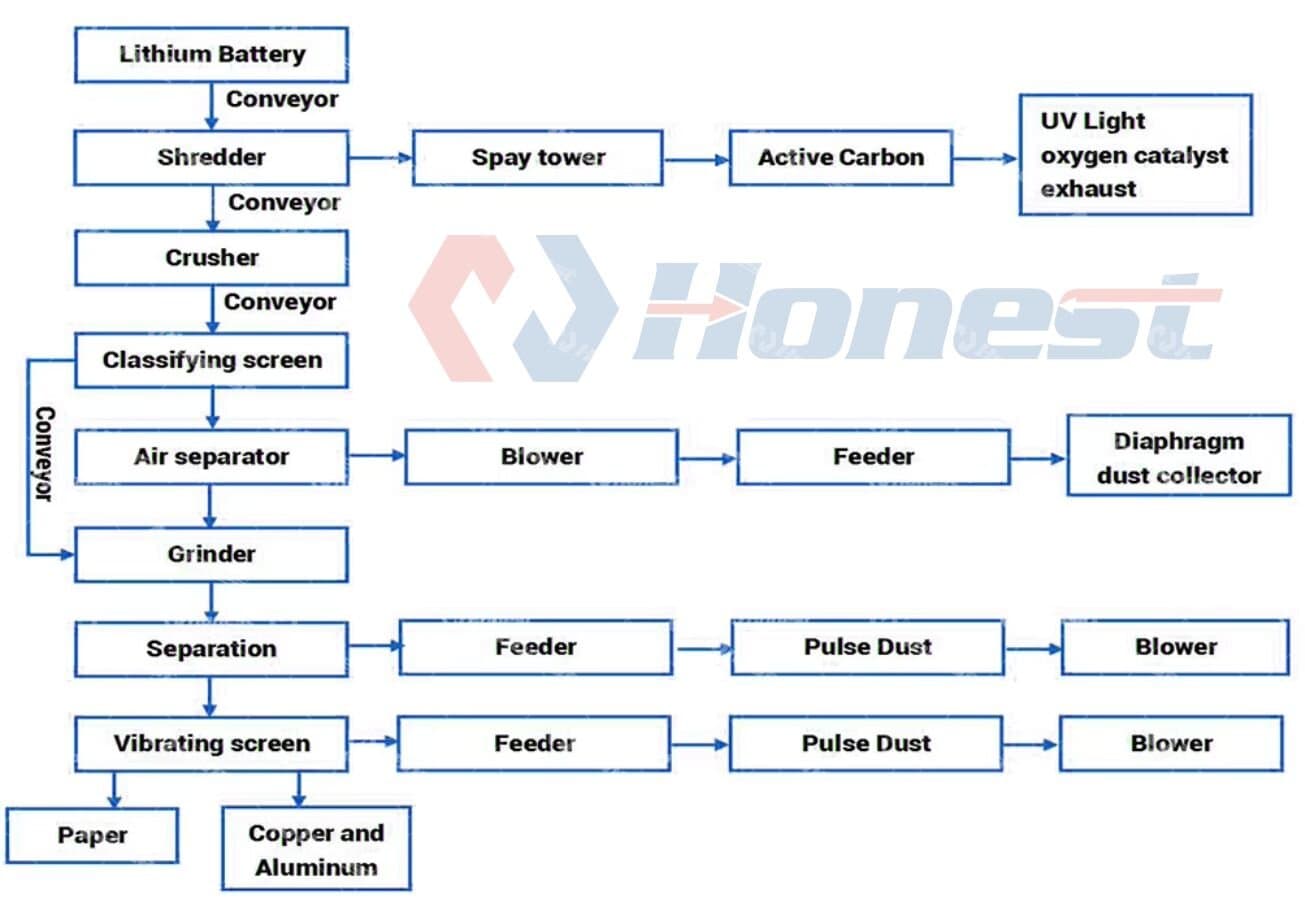

The treatment process of the lithium-ion battery recycling line is mainly to use mechanical equipment to carry out the processes of crushing, magnetic separation, winnowing, crushing, gravity separation, and screening after the recycled waste batteries are discharged, so that the positive and negative pole pieces The powder and copper and aluminum foil are effectively separated, and the battery is treated as a material containing valuable metals.

Raw Material

This lithium ion battery recycling plant offers complete recycling solutions and equipment for cylindrical cells, prismatic cells, pouch cells negative plates, positive plates and more.

Final Products

The final products are black mass, aluminum granules, copper granules, plastic, steel shell and separator plastic etc. The output will vary depending on the type of battery.

Technical Parameters

| Model | Size | Power | Capacity |

| HN-LDC-500 | 40m*11m*8m | 361Kw | 500kg/h |

| HN-LDC-1000 | 50m*12m*8m | 442Kw | 1000kg/h |

Technical Standards

| Feature Item | Indicator Requirments |

| Recovery Rate of Metallic Aluminum | >98% |

| Powder Recovery Rate | >98% |

| Content of Powder In Metal Aluminum | <2% |

| Content of Metallic Aluminum In Powder | <2% |

| Other | Contain dust collecter with not pollute |

| Qualified Rate | 99% |

| Failure Rate | <1% |

| CMR | ≥1.67 |

Lithium-ion Battery Recycling Brief Introduction

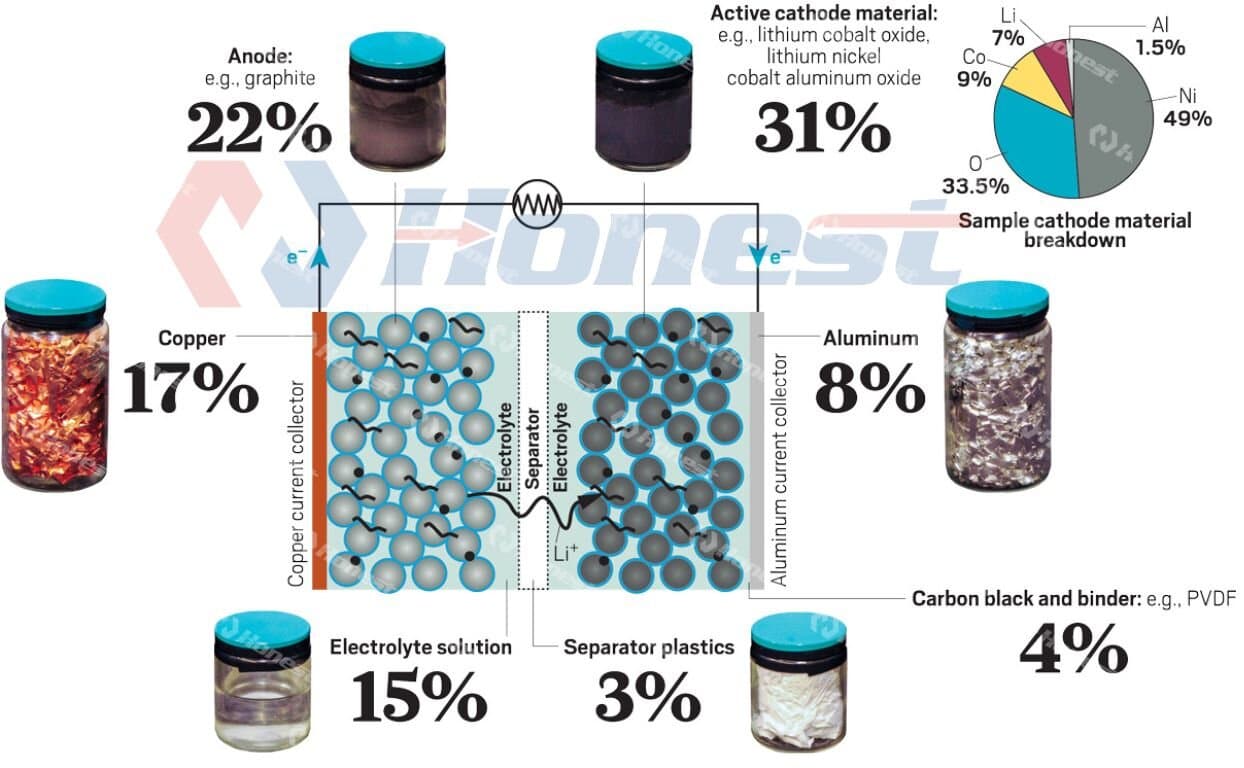

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte anddiaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides ofan aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector. At present, the research on the recycling of wastelithium batteries is mainly focused on the recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficientseparation and recovery of waste lithium batteries.

Over the years, we have been engaged in the research, development, andproduction of lithium-ion battery recycling equipment. We have tested overa hundred types of lithium-ion battery recycling and our technology hasbeen continuously improving. Our aim is to provide our customers with moreprofessional and reliable recycling equipment.

Lithium-ion Battery Recycling Technology

The shredder shreds the lithium-ion batteries into small pieces, the hammer crusher carries out secondary crushing of the shredded material, and the grinder grinds the crushed material into fine powder. The separator separates the ground material, the magnetic separator separates the magnetic metal such as nickel from the metal mixture, and the gravity separator utilizes the density difference of the material to further separate the metal in the fine particles. Grading sieve sieves the material processed by the separator, and wind separator separates materials with different densities by wind force. The dust collector collects and releases the dust generated during the recycling process, the pulse purifier cleans the dust generated during the operation of the whole system, and the high-pressure fan maintains the whole system in a negative pressure state to collect the materials and purify the air to prevent the dust from leaking. Through the combined process of hammer crushing, vibratory stripping and screening and air separation, the resource utilization of metal and positive and negative powder in the positive and negative materials of waste lithium-ion batteries is realized. Hammer vibration stripping and screening separation, according to the particle size and shape differences in the initial separation of metal and positive and negative electrode powder. For low metal grade crushed particles with particle size of 0.125~0.250mm, effective separation of metal and positive and negative electrode powder is realized through wind separation. The whole set of equipment operates under negative pressure without dust leakage, and the separation efficiency reaches more than 98%.

Lithium-ion Battery Recycling Equipment Workflow

Shredder: Shredded lithium batteries into smaller pieces.

Hammer crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Separation machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Pulse purifier (air cleaner): Clean all the dust produced during the operation of the wholesystem.

Classifying screen:Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic machine: Separate nickel from the metals.

Gravity separator:Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the materialsand purity the air.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

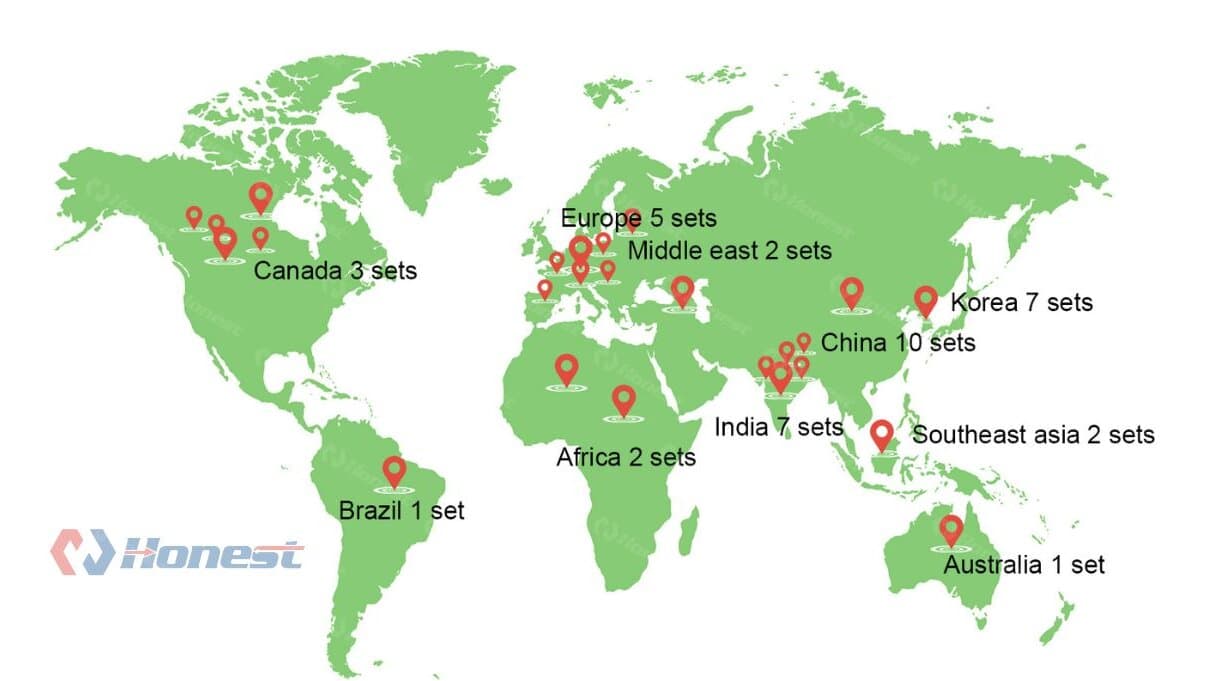

Lithium-ion Battery Recycling Equipment Sales Areas

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export