Equipment Features

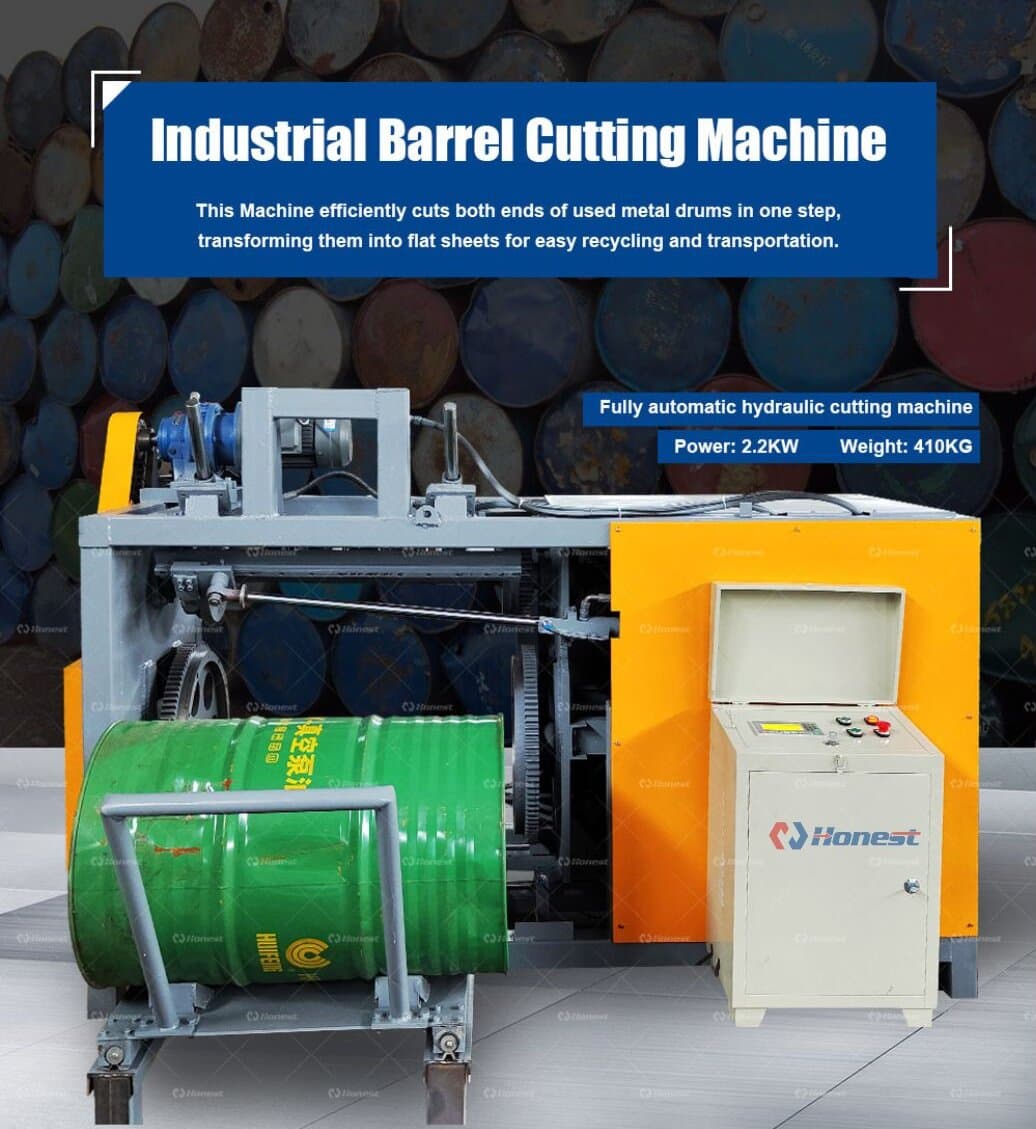

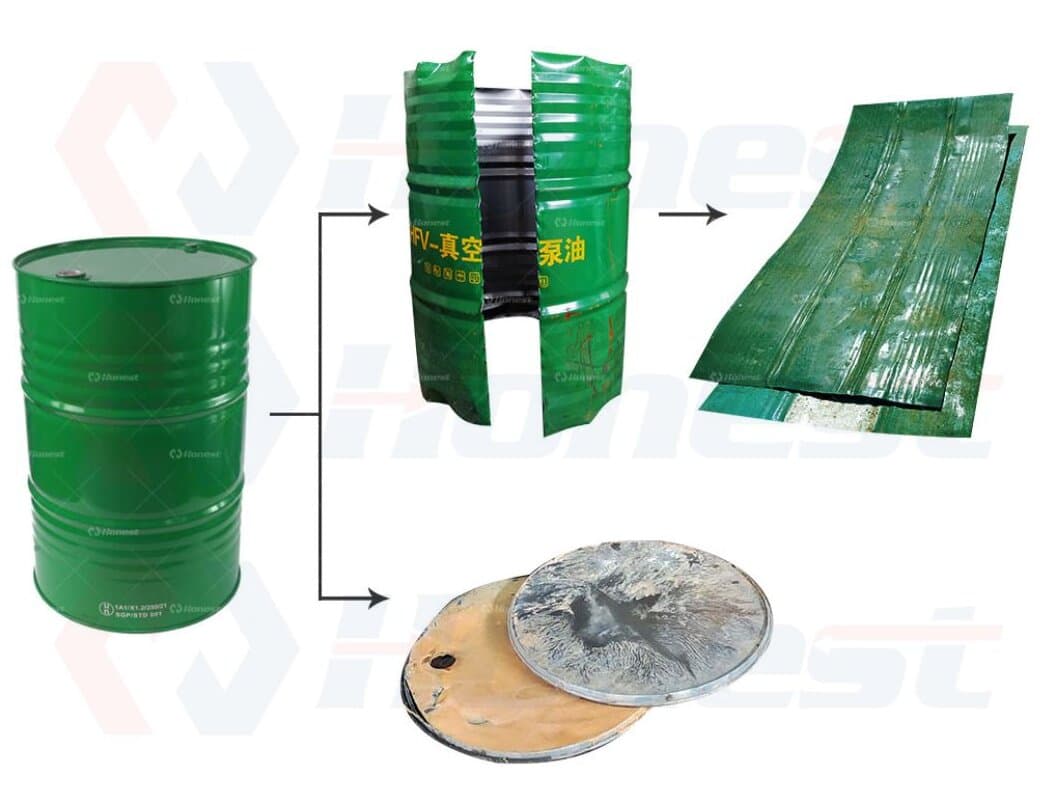

Main Applications:This Machine efficiently cuts both ends of used metal drums in one step, transforming them into flat sheets for easy recycling and transportation.

Raw Materials:Waste metal drums

Main Final Products:Flat metal sheet

If you want to start your recycling business, feel free to contact us.

Integrated Cutting System: Combines cap cutting, body cutting, and flattening into one complete system. This equipment is ideal for converting waste drums into reusable iron sheets, contributing to efficient material recovery and environmental sustainability.

Industrial Barrel Drum Cutting Machine Product Usage /Application:

This high-efficiency industrial drum cutting machine is designed for waste oil and paint drum recycling. Equipped with a robust hydraulic system, it enables simultaneous cutting of both drum caps and bodies, significantly improving operational efficiency in recycling plants.

Technical Parameters

| Equipment Name | Power | Weight | Dimensions |

| Manual Drum Top Cutting Machine | 2.2KW | 230KG | 1200(850)*700*1400 |

| Hydraulic Drum Top Cutting Machine | 2.2KW/ Hydraulic Unit 1.5Kw | 280KG | 1200(850)*700*1400 |

| Manual Drum Cutting All-in-One Machine | 2.2KW | 380KG | 1850*1200(850)*1400 |

| Hydraulic Drum Cutting All-in-One Machine | 2.2KW/ Hydraulic Unit 1.5Kw | 410KG | – |

| Single Drum Flattening Machine | 2.2KW | 380KG | – |

| Drum Body Flattening Machine | 2.2KW | 460KG | 1650*1800(1000)*1150 |

| Double Drum Flattening Machine | 2.2KW | 480KG | 1700*700*1150 |

| Manual Drum Top and Body Flattening All-in-One Machine | 3KW | 600KG | Single Unit Flatten 2250*1800(1000)*1400 |

| Hydraulic Drum Top and Body Flattening All-in-One Machine | 3KW/ Hydraulic Unit 1.5Kw | 650KG | – |

| Vertical Barrel Cutting Machine | 2.2KW/ Hydraulic Unit 1.5Kw | 450KG | – |

Key components of Industrial Barrel Drum Cutting Machine

Integrated Cutting System: Combines cap cutting, body cutting, and flattening into one complete system. The machine separates iron drums by rolling and shearing along the welded seam in the middle of the drum. The system includes:

Cap Cutting Unit – Removes the top of the drum.

Body Cutting Unit – Splits the cylindrical body.

Flattening Unit – Flattens the drum body into sheets for reuse or further processing.

EFFICIENT CUTTING : The variable-speed control system automatically adjusts the cutting speed according to different materials and thicknesses, ensuring precise and efficient operation.

SAFE OPERATION : Equipped with multiple safety features, including an emergency stop button, protective safety guards, and an automatic power-off system, the machine ensures maximum operator safety during use.

AUTOMATED PROCESSING : With a push-pull feeding system, the equipment performs both drum lid and body cutting in a single automated operation — minimizing manual intervention and increasing productivity.

EASY MAINTENANCE : A user-friendly design with detachable components allows for quick and easy maintenance, as well as fast blade replacement, reducing downtime and operational costs.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export