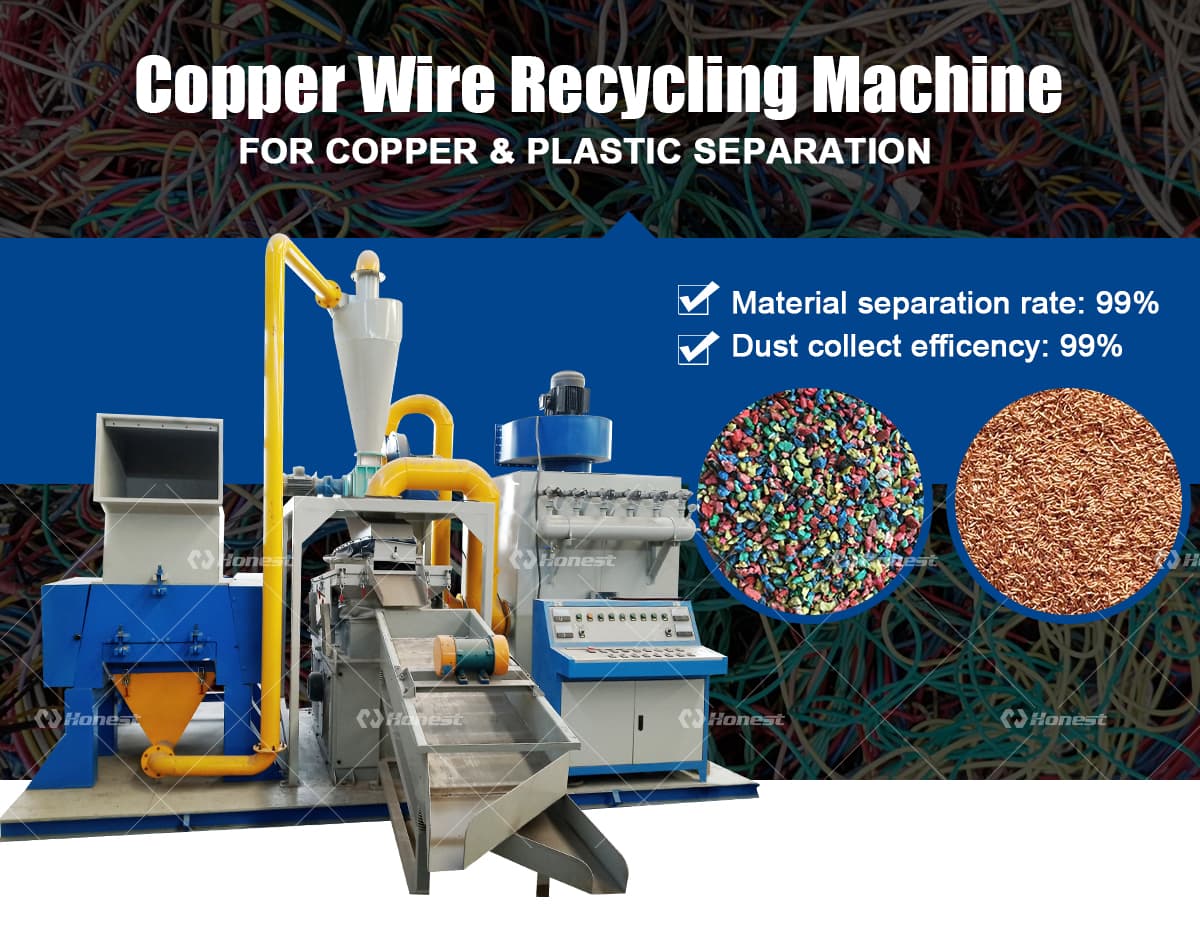

Equipment Features

Main Applications:Recycling all kinds of waste copper wire and cable

Raw Materials:Automobile wires, motorcycle wires, computer chassis wires and communication cables, etc.

Main Final Products:Copper and Plastic

If you want to start your recycling business, feel free to contact us.

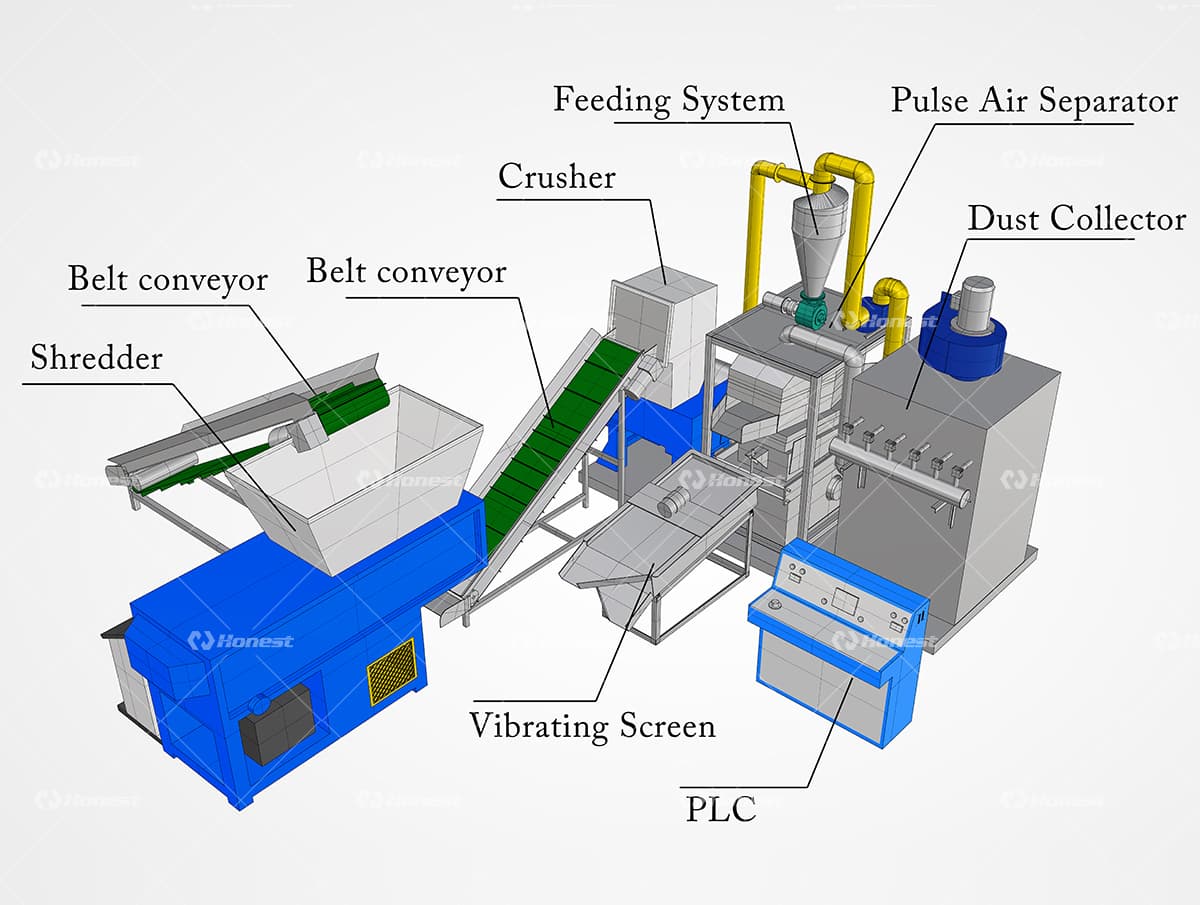

This Cable Wire Recycling Plant adopts advanced design, reasonable structure and reliable operation. The production line can not only handle coarse wires that can be processed by ordinary crusher, but also has good separation effect for very fine wires. The current production line consists of Belt conveyor, Shredder, Crusher, Vibrating Screen, Feeding System, Pulse Air Separator, Dust Collector and PLC. Copper is separated from plastic with a separation efficiency of up to 99%.

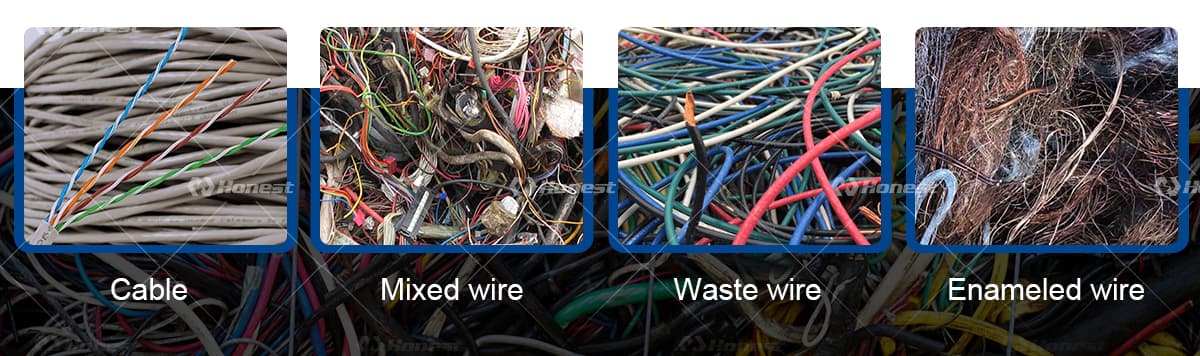

Raw Material

The machine can recover copper wires with a diameter of 0.3mm-35mm, such as automobile wires, motorcycle wires, power cables, communication cables, signal cables, and other miscellaneous wires that can’t be processed by the cable stripping machine.

Final Products

The copper wire recycling machine will turn the waste cable or wire into plastic particles and copper particles after crushing. Copper is separated from plastic and the separation efficiency can reach 99%.

Technical Parameters

| Model | Capacity | Weight | Size (m) | Power |

| HN-TMJ-100 | 100-200kg/h | 1850kg | 2.2x2x2.3 | 28kw |

| HN-TMJ-300 | 200-300kg/h | 2500kg | 3.2×2.1×2.3 | 39kw |

| HN-TMJ-500 | 400-500kg/h | 3850kg | 6.2x5x3.3 | 68kw |

| HN-TMJ-800 | 700-800kg/h | 5500kg | 10.4×2.1×3.3 | 75kw |

| HN-TMJ-1000 | 800-1000kg/h | 8200kg | 12×4.1×4.5 | 95kw |

Cable Wire Recycling Plant Brief Introduction

Belt conveyor: There are two belts for transferring materials.

Shredder: Preliminary shredding of materials.

Crusher: crushes the materials.

Vibrating Screen: screening materials of different sizes.

Feeding System: Used to input materials to be processed into the equipment.

Pulse Air Separator: Separates the material by pulse air flow.

Dust Collector: Collects dust generated during the process.

PLC: Used for automatic control of equipment operation.

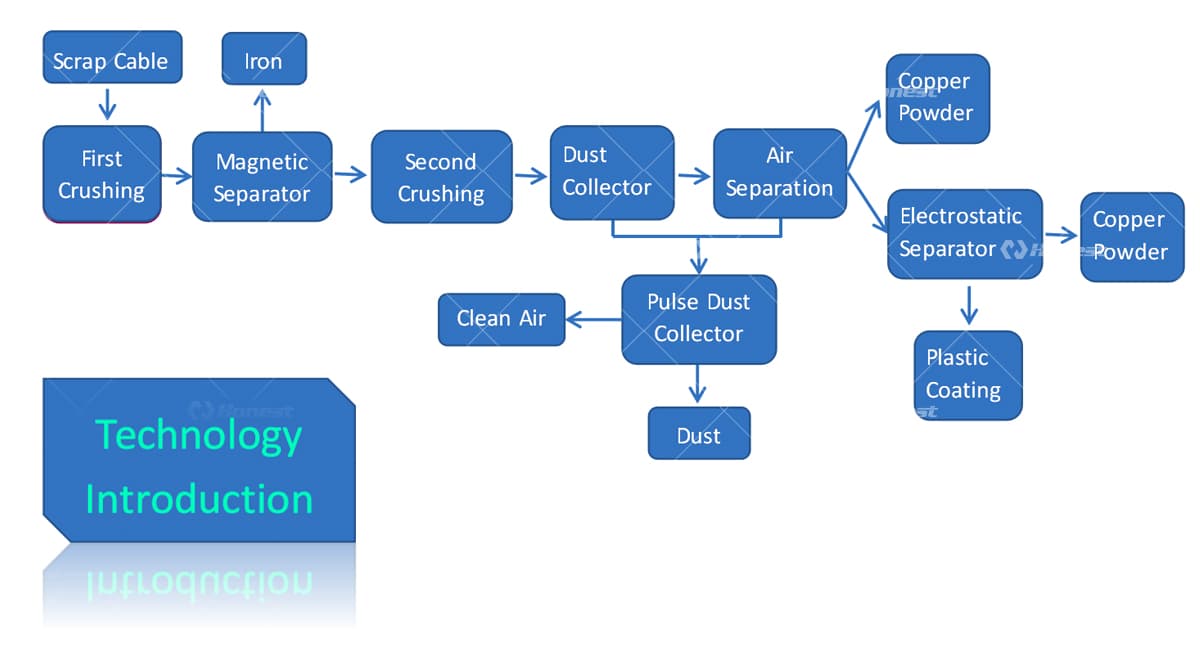

Cable Wire Recycling Equipment Workflow

aste cables or wires are shredded and crushed into plastic particles and copper particles. The mixture jumps forward like a wave on the surface of the vibrating screen. By means of the air flow function and the linear excitation of the screen box, the sheaths and cores are separated and copper particles, plastic particles and mixtures are obtained from the different discharge areas. Each step is controlled by a PLC program that starts and stops at the touch of a button. The operator interface video shows the working status of important components and intelligently indicates equipment faults.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export