Equipment Features

Main Applications:Recycling and sorting of C&D and MSW

Raw Materials:Mixed waste, plastics, metals, wood, bricks

Main Final Products:Plastics, metals, RDF, bricks, organics

If you want to start your recycling business, feel free to contact us.

The Urban Garbage Recycling Line combines multiple processes, including shredding, trommel screening, magnetic separation, air classification, and manual or automated sorting, to extract reusable resources such as plastics, metals, wood, bricks, and organic matter. Whether you are dealing with complex demolition residues or mixed urban garbage, this solution is engineered to improve recycling efficiency, reduce environmental burden, and support sustainable urban development.

Our recycling equipment is a customized productPlease don’t hesitate to contact us if you are interested.

Construction and Municipal Waste Recycling Line Product Usage / Application:

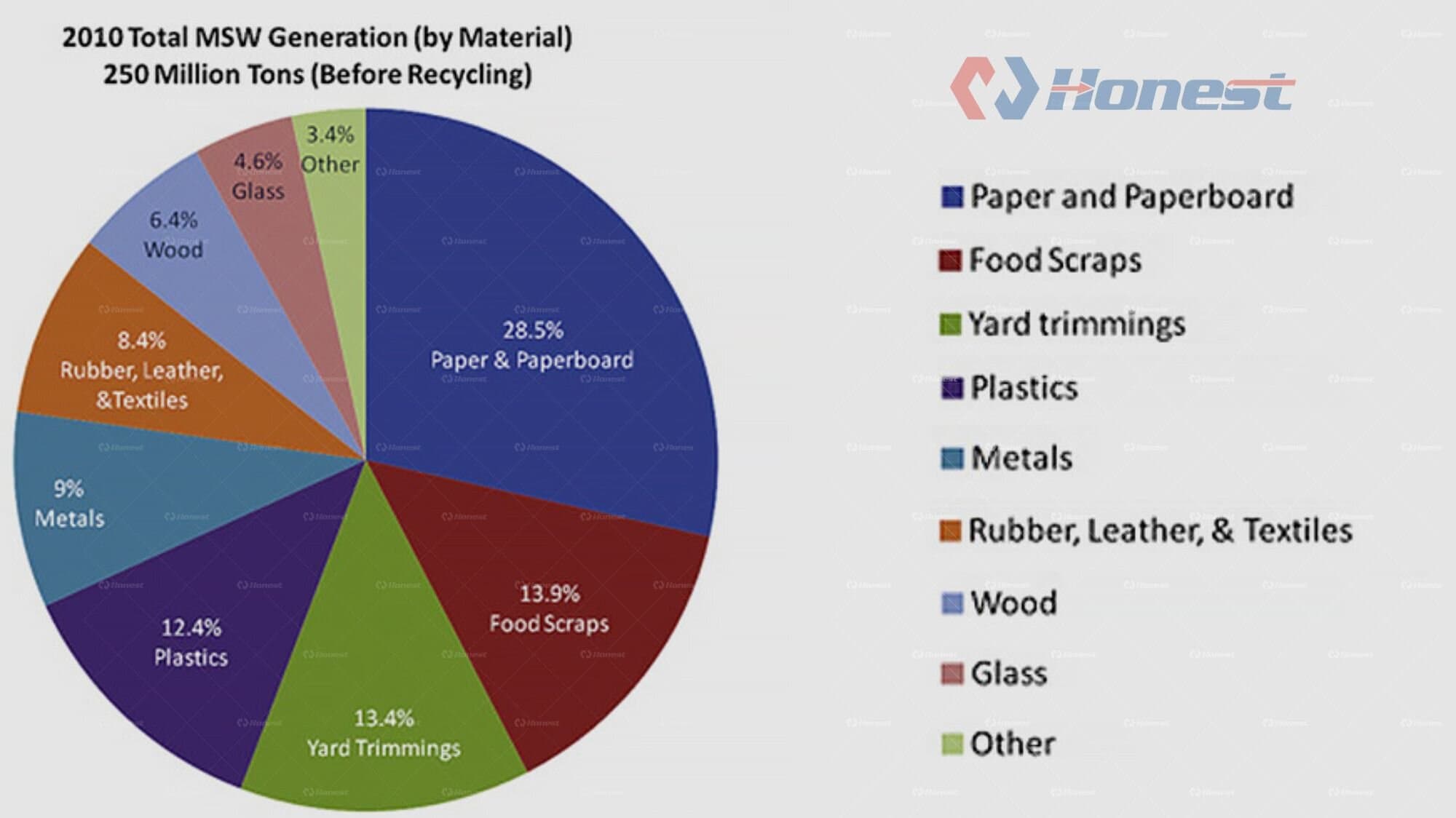

Municipal solid waste primarily comes from three major sources:

Domestic Waste: Generated from households and public areas, including residential buildings, streets, litter bins, parks, and coastal zones.

Commercial Waste: Originating from offices, shops, restaurants, hotels, and private estates

Industrial Waste: Produced by manufacturing and other industries (excluding construction & demolition waste, chemical waste, and other hazardous categories).

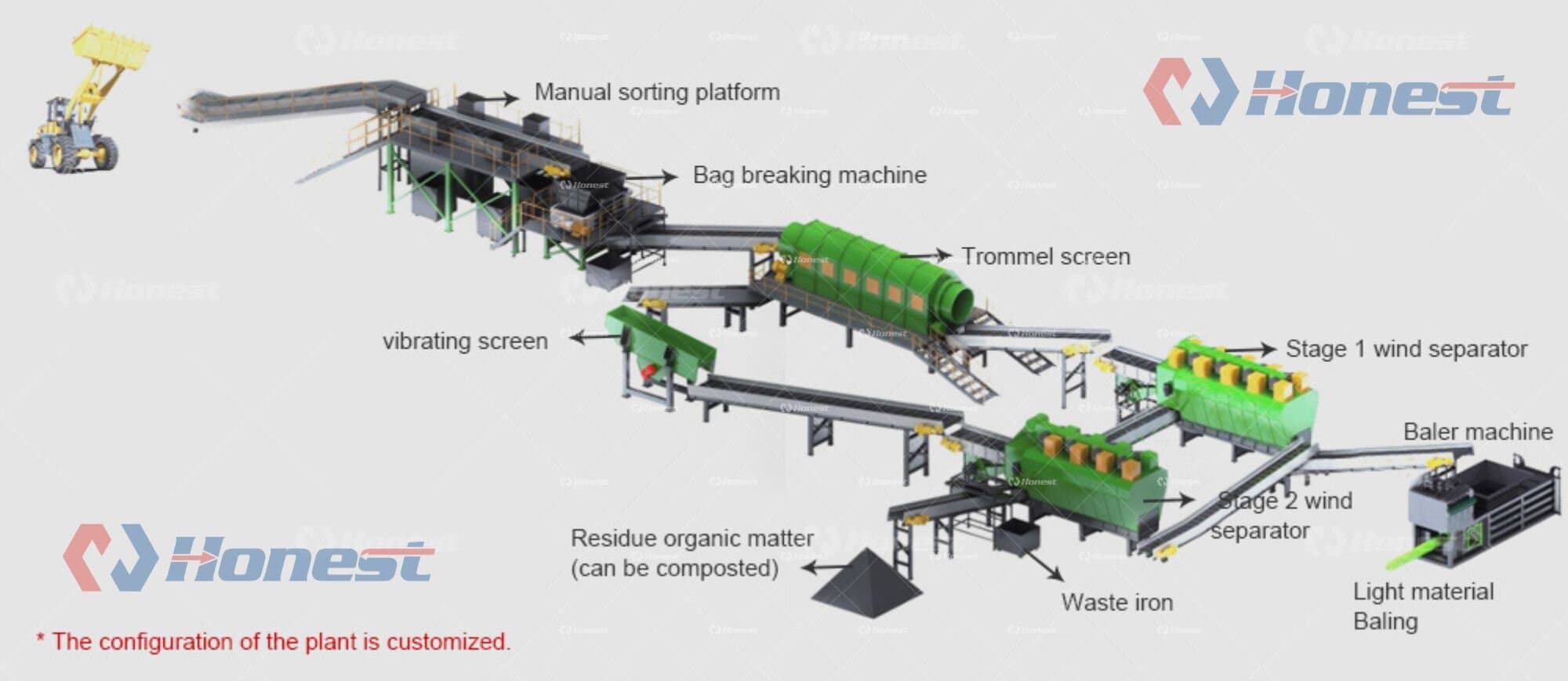

Product Structure Construction and Municipal Waste Recycling Line

The system consists of a forklift feeding station, chain plate conveyor with leveling device, manual sorting platform, bag breaker, magnetic separator, trommel screen, air separator, and baler. Waste is fed, manually sorted, crushed, magnetically separated, screened by size, air-classified by density, and finally baled for efficient recycling and disposal.

The forklift truck sends the domestic garbage to the chain plate conveyor, which evenly transports the materials to the manual sorting platform through the material homogenizing device, and after manual sorting of interferences, the materials are transported to the bag breaker, and the materials are crushed. The crushed materials are sorted out by the magnetic separator, and the remaining materials are sent to the drum screen,and the dregs and other materials screened by the drum screen are transported to the under- screen stacking area by the under-screen conveyor, waiting for subsequent processing, and the oversize materials are transported by the conveyor to the air separator for sorting. Light materials are transported to the baler by the over-sieve conveyor for packing, and under-sieve materials (heavy materials) are transported to the under-sieve stacking area by the under-sieve conveyor for stacking, waiting for subsequent processing.

Key components of Construction and Municipal Waste Recycling Line

CHAIN SCRAPER CONVEYOR : During the working process, the conveyor can uniformly and continuously feed blocky and granular materials into the crushing device.

MANUAL SORTING PLATFORM : The manual sorting platform is controlled by a frequency converter. Several sorting stations are set on both sides, each station corresponding to a garbage collection hopper, such as glass, textiles, wood, waste paper, aluminum, and selected by hand.

BAG BREAKING MACHINE : Effectively crushing the packaging materials and facilitating the screening effect.

TROMMEL SCREEN : The drum screen controls the garbage sorting through the particle size, and the sorting accuracy is high. The sieve aperture on each section of the drum sieve is the same.

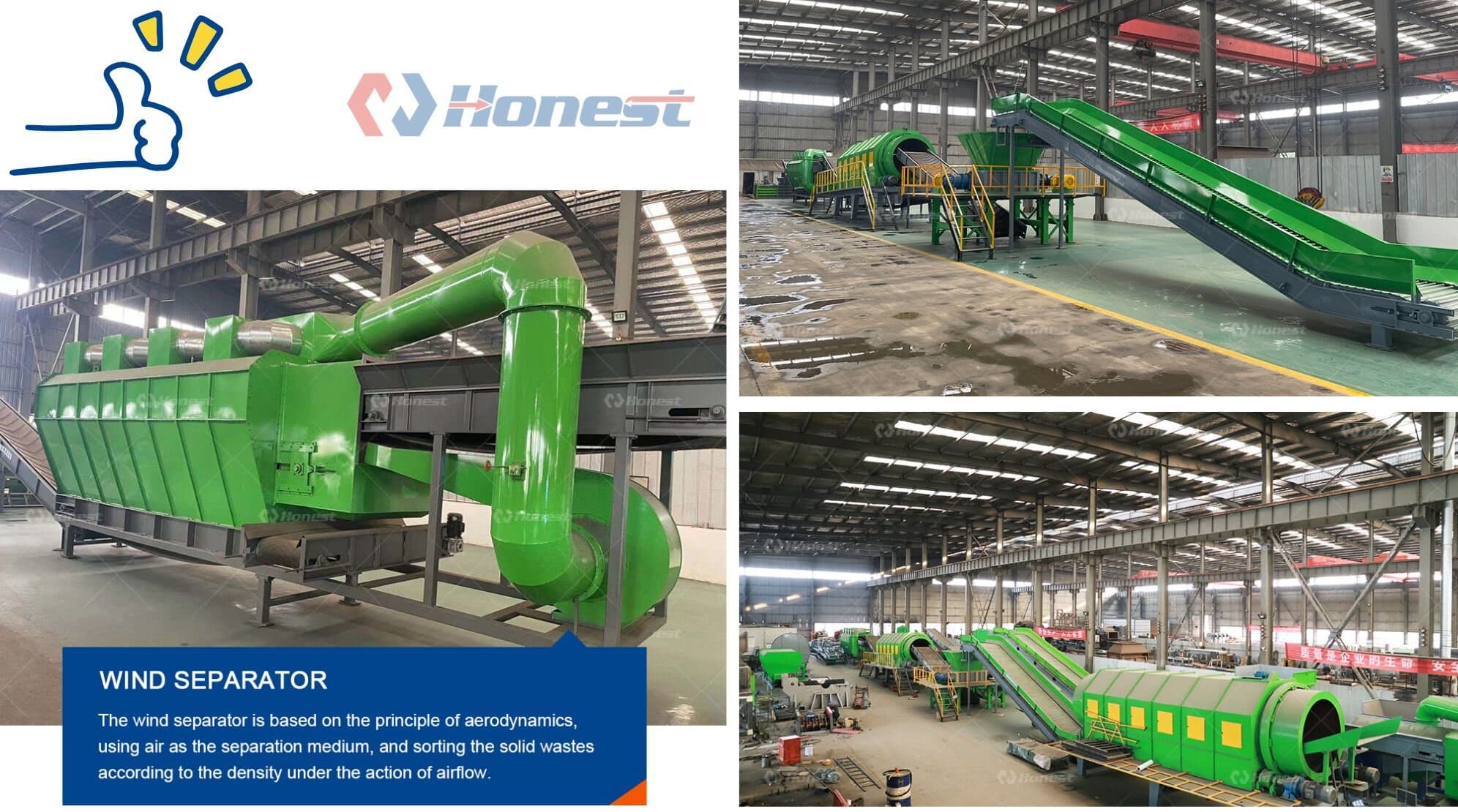

WIND SEPARATOR : The wind separator is based on the principle of aerodynamics air as the separation medium, and sorting the solid wastes according to the density under the action of air flow.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export