Equipment Features

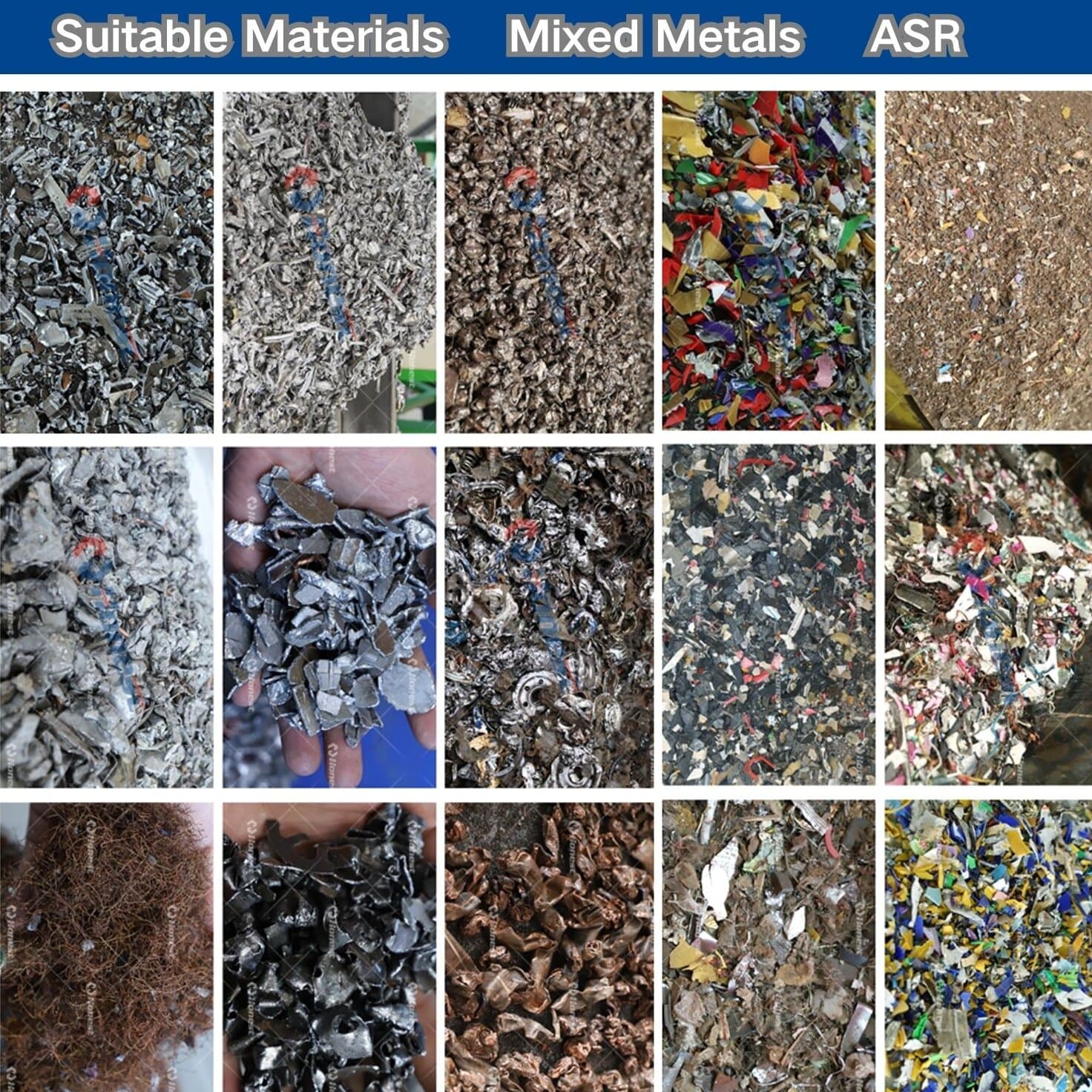

Main Applications:Efficiently Recover Valuable Metals from Shredder Tailings

Raw Materials:ASR and steel mill tailings.

Main Final Products:Iron,Copper, aluminum, stainless steel.

If you want to start your recycling business, feel free to contact us.

The ASR Separating Recycling Line is designed for recycling and separating valuable metals from Automotive Shredder Residue (ASR) generated after shredding end-of-life vehicles, household appliances, and other mixed scrap materials.

ASR Separating Recycling Line Product Usage / Application:

It processes ASR containing non-ferrous metals, stainless steel, plastics, rubber, glass, foam, and other light fractions left after initial ferrous metal separation. The system efficiently produces cleanly separated non-ferrous metals (copper, aluminum, zinc), stainless steel, and sorted non-metallic fractions for reuse or further processing.

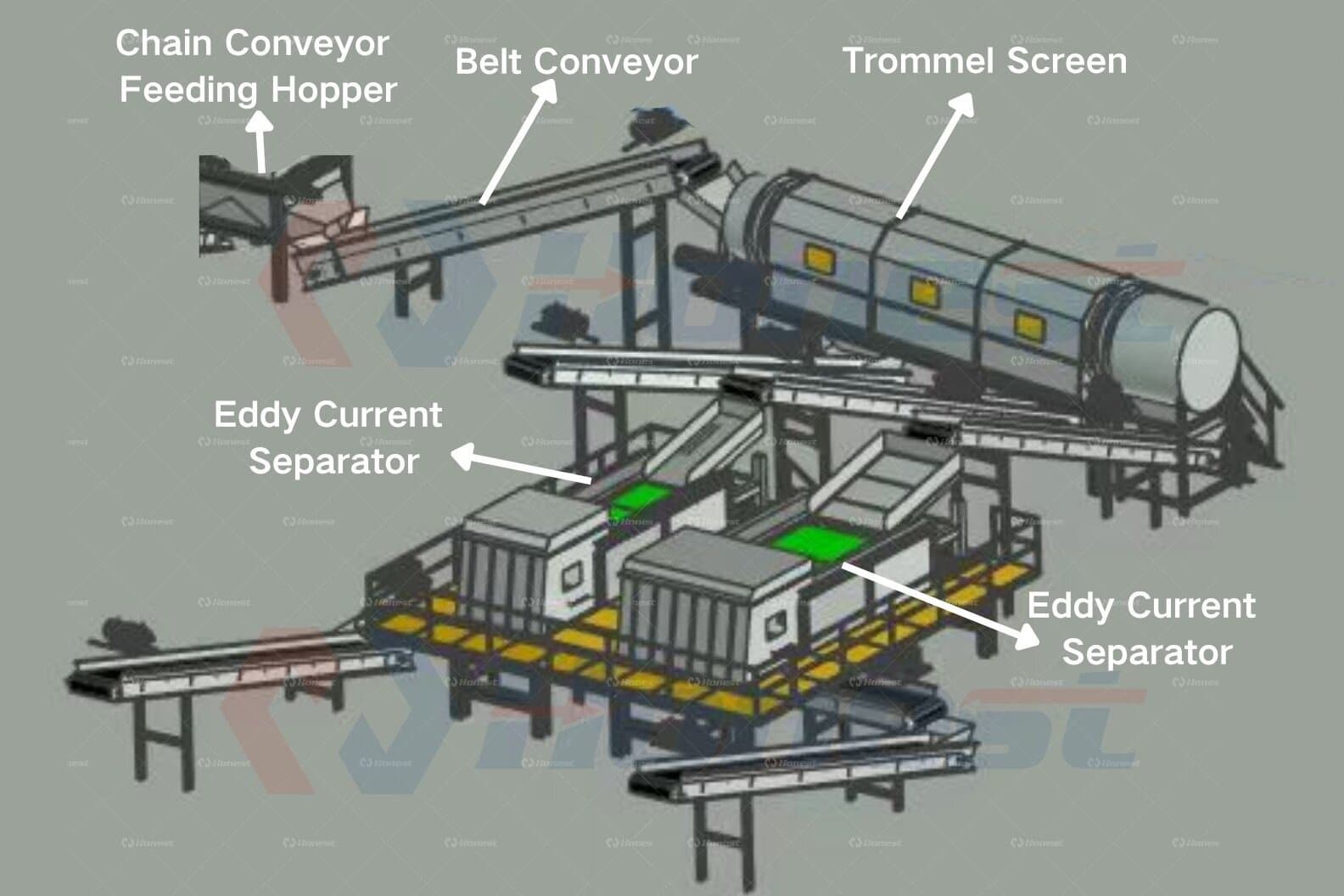

Product Structure ASR Separating Recycling Line

Our ASR Recycling Line is designed to efficiently extract these valuable materials through a fully automated structure process. The process integrates drum screening, vibrating screening, magnetic separation, and eddy current separation to extract non-ferrous metals from complex mixed waste.

Bulk material is fed via a chain plate hopper and conveyed to the drum screen, which performs precise particle size classification into <5mm, 5–15mm, 15–30mm, 30–60mm, and 60–100mm fractions. The finer the grading, the higher the sorting accuracy in subsequent steps. Classified materials then enter the eddy current separator, which uses electromagnetic repulsion to eject copper, aluminum, and other non-ferrous metals from the waste stream. The concentric rotor design delivers outstanding performance for small particles between 5 and 20mm, ensuring high recovery rates.

Optional equipment such as air separators, self-unloading magnetic separators, full-metal sorters, X-ray sorting systems, and metal color sorters can be added to further improve purity and sorting range.

Scrap Metal Shredding Crushing Sorting Recycling Line

We provide a complete scrap metal recycling line designed for crushing, separating, and recovering various ferrous metals, non-ferrous metals, and non-metallic materials, with tailored solutions to match your specific materials and recycling goals.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export