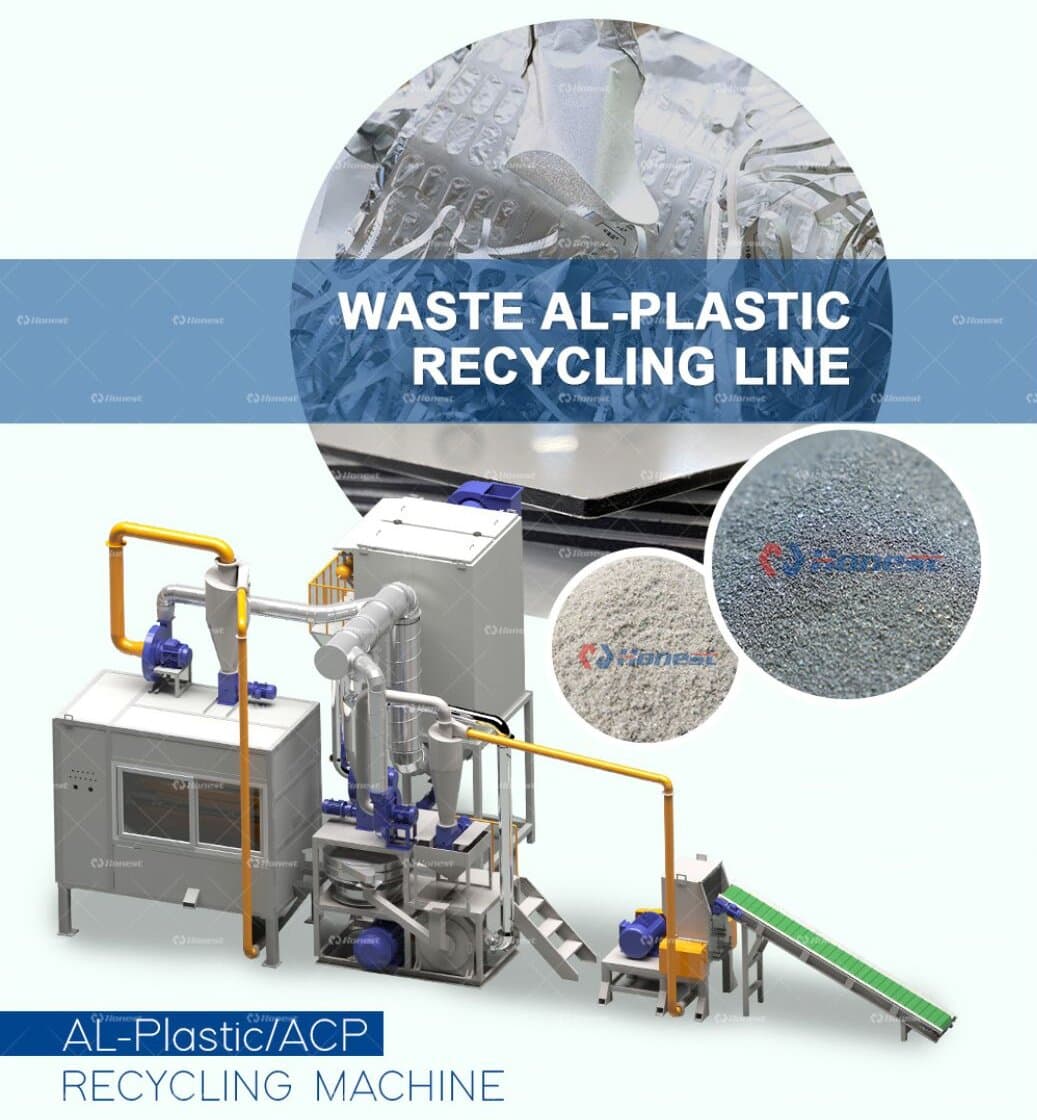

Equipment Features

Main Applications:Recycling aluminum-plastic composites

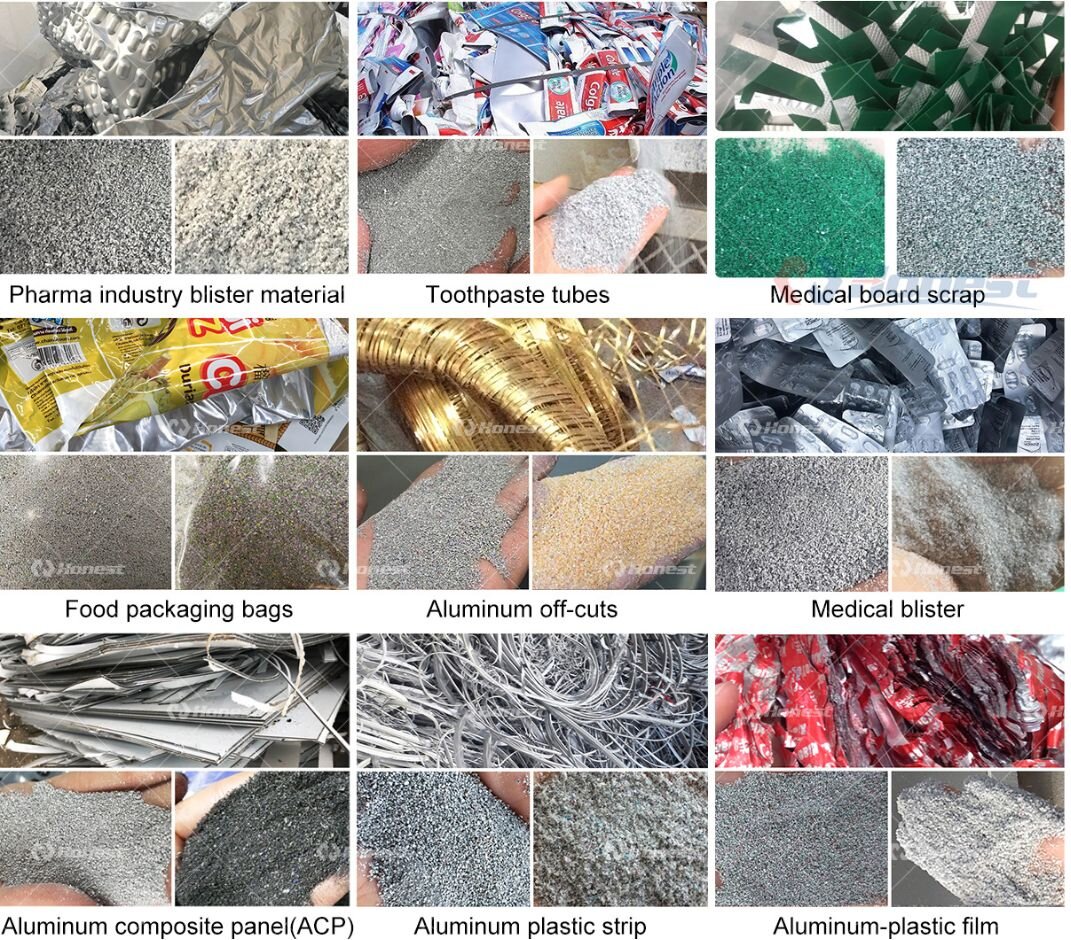

Raw Materials:Pharma industry blister material,Food packaging bags,Aluminum composite,panel(ACP),Toothpaste tubes,Aluminum off-cuts,Aluminum plastic strip,Medical board scrap,Medical blister,Aluminum-plastic film

Main Final Products:Aluminum and Plastic

If you want to start your recycling business, feel free to contact us.

The Aluminum Plastic Separation Recycling Plant is a specialized system designed to efficiently separate and recycle aluminum and plastic composite materials, commonly found in Pharma industry blister material,Food packaging bags,Aluminum composite,panel(ACP),Toothpaste tubes,Aluminum off-cuts,Aluminum plastic strip,Medical board scrap,Medical blister,Aluminum-plastic film.

Raw Material

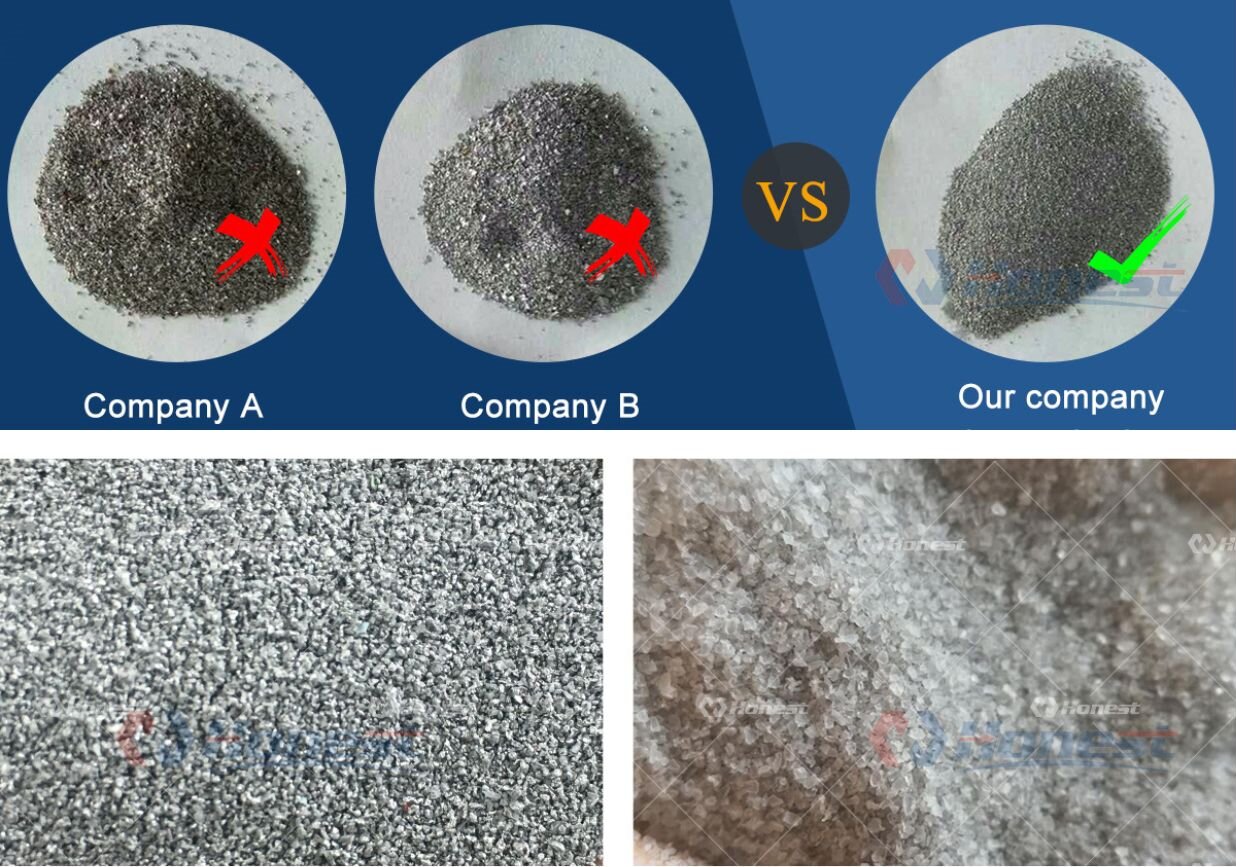

The following picture is the result of testing the Aluminum Plastic Film Recycling Machine/Foil Plate Recycle Machine Manufacture by some customers. We will save and send samples of sorted aluminum powder and plastic powder for our customers, You can send your materials to us and we will test the machine for you without charging any fees.

Pharma industry blister material,Food packaging bags,Aluminum composite,panel(ACP),Toothpaste tubes,Aluminum off-cuts,Aluminum plastic strip,Medical board scrap,Medical blister,Aluminum-plastic film.

Final Products

Compare Aluminum Powder With Other Suppliers

Aluminum Powder and Plastic Powder

Technical Parameters

| Model | Power (Kw) | Weight (T) | Capacity (Kg/H) |

| HN-AP-300 | 62 | 7.5 | 300 |

| HN-AP-500 | 98 | 12.5 | 500 |

| HN-AP-1000 | 170 | 19.5 | 1000 |

| TIPS:

1. The Price depends on your capacity and configuration of the machinery; 2. Working voltage: 380±10V (415V, 440V also can be custom. |

|||

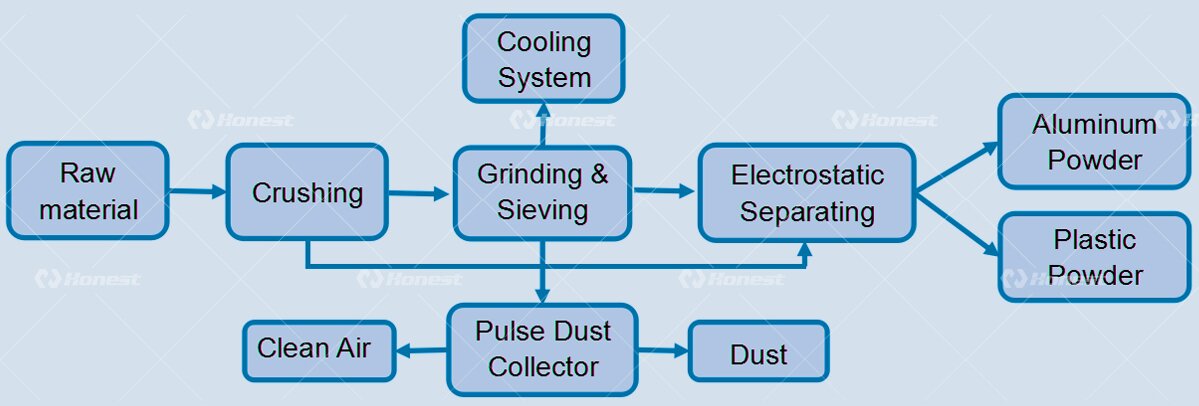

Aluminum Plastic Recycling Equipment Workflow

The aluminum-plastic recycling workflow begins by feeding raw materials into a high-capacity knife crusher for primary reduction into uniform 10mm fragments. These fragments are then transferred to a water-cooled scroll mill for fine grinding, where the material is decomposed into a mixture of aluminum and plastic fines. To maintain material integrity and equipment stability, an integrated cooling system regulates the temperature throughout this process. The ground material then enters a rotary screen for size classification, where oversized particles are automatically returned to the mill for re-grinding, while the qualified fine powder proceeds to the final separation stage. This powder is processed through a high-voltage electrostatic separator equipped with a six-roller system, which utilizes the different electrical conductivities of metal and plastic to achieve a precise separation of the two materials. Throughout the entire operation, a pulse dust collector captures generated particulates to ensure that only clean air is discharged, maintaining a clean and efficient production environment.

Aluminum Plastic Separating Recycling Plant Brief Introduction

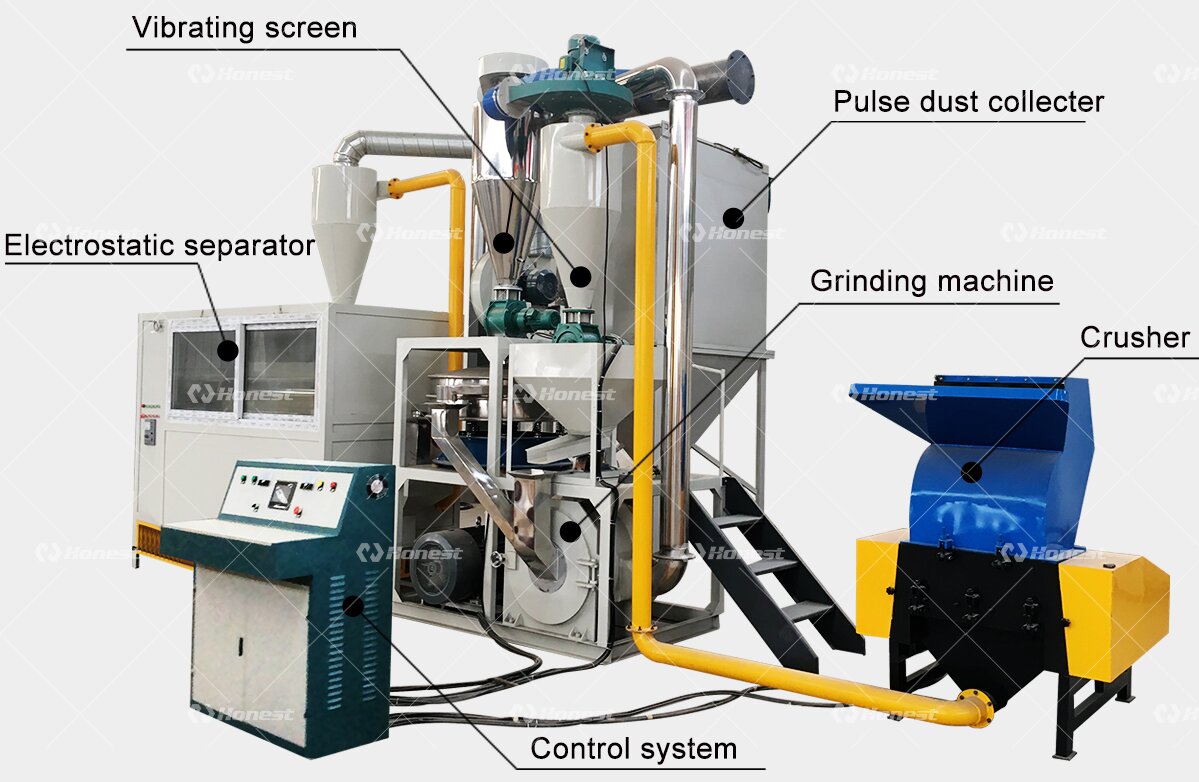

Equipment Composition: Including Crusher, Grinding machine, Vibrating screen, Electrostatic separator, Pulse dust collector and Control system.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export