-

Solar PV Panel Recycling Plant

The Solar PV Panel Recycling Plant effectively extracts reusable materials such as silicon, aluminum, copper and glass through the processes of disassembly, crushing and separation, which not only reduces the pollution of harmful substances to the environment, but also realizes the recycling of resources.

-

Lithium-ion Battery Recycling Plant

Our Lithium-ion Battery Recycling Plant efficiently separates electrode materials, current collectors, and casings from used batteries through pre-discharge, mechanical crushing, and multi-stage physical sorting. This process enables the effective recovery of valuable metals, including aluminum, copper, iron, and nickel.

-

Solar Panel Thermal Treatment Recycling Line

The recycling line integrates robotic feeding, intelligent dismantling,patented pyrolysis, multi-stage separation, and classified materialcollection into a stable, continuous, and scalable recycling system.

-

E Waste Recycling Plant

This integrated electronic waste recycling plant effectively recovers precious metals like gold, silver, copper, and aluminum, as well as recyclable materials such as resin powder from electronic waste. The process involves advanced pretreatment, multi-stage crushing, precise sorting, and the safe handling of hazardous substances.

-

Cable Wire Recycling Plant

The Cable Wire Recycling Plant efficiently recovers non-ferrous metals like copper and aluminum, along with plastic insulation, from waste cables and wires using advanced mechanical crushing, multi-stage sorting, and fine separation technology.

-

Waste Refrigerator Recycling Plant

The waste refrigerator recycling plant combines safe refrigerant recovery, efficient mechanical disassembly, and precise material sorting technologies. This system effectively handles harmful substances like Freon to prevent environmental damage, while efficiently recovering valuable resources such as steel, copper, aluminum, and plastics.

-

UBC Cans Paint Removing Plant

The UBC Cans Paint Removing Plant utilizes advanced pyrolysis or mechanical stripping technology to quickly and thoroughly remove paint and impurities from used aluminum beverage cans, significantly enhancing the purity and value of recycled aluminum.

-

Tetra Pak Recycling Plant

The Tetra Pak Recycling Plant employs advanced physical separation technology to efficiently separate and recycle the pulp, aluminum foil, and plastic layers in Tetra Pak containers. The production line integrates crushing, hydraulic pulping, screening, pressing, and drying processes to ensure high purity and maximize the reuse value of the recycled materials.

-

Aluminum Plastic Separating Recycling Plant

The Aluminum Plastic Separation Recycling Plant is a specialized system designed to efficiently separate and recycle aluminum and plastic composite materials, commonly found in beverage cans, packaging, and medical blister packs. The plant uses advanced mechanical separation technologies, including air classification, vibrating screens, and electrostatic separation, to effectively isolate aluminum from plastic.

-

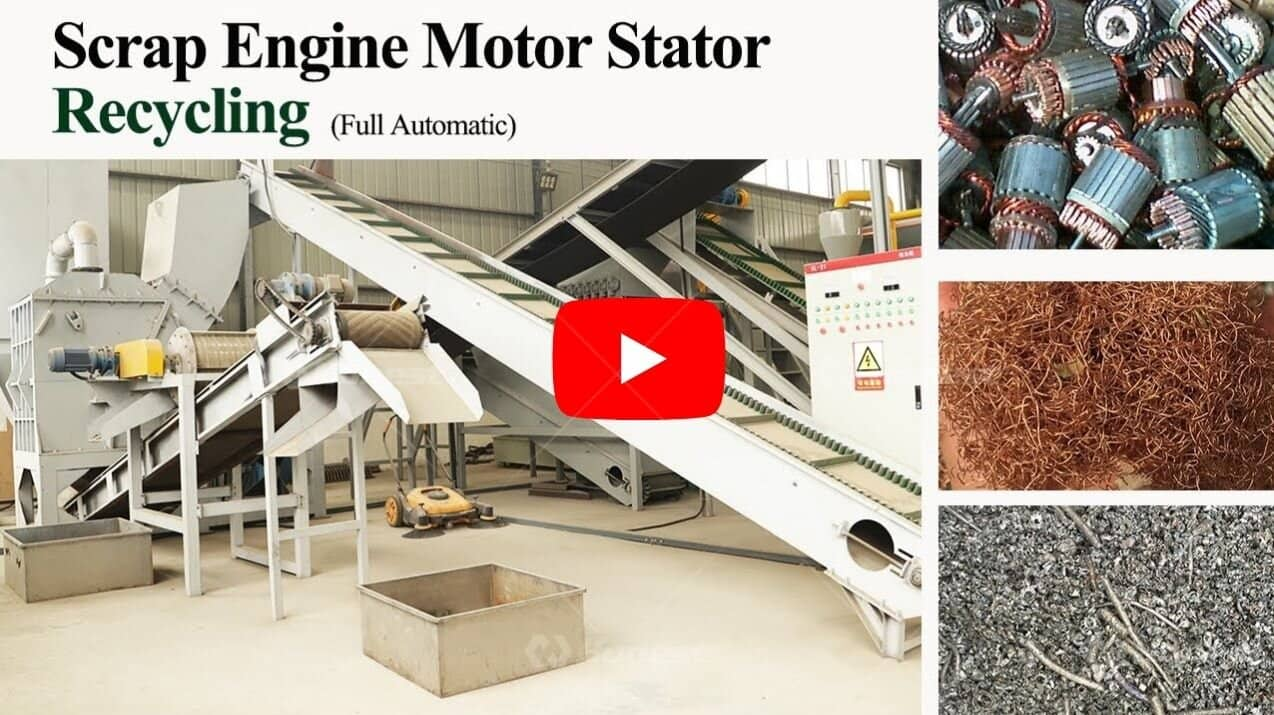

Scrap Motor Stator Recycling Plant

Scrap Motor Stator Recycling Plant is a specialized facility designed to efficiently recover valuable metals, mainly copper and steel, from discarded motor stators. Using advanced technologies such as shredders, cutters, and hydraulic presses, the plant dismantles the stators and separates the copper windings from the iron core. Electromagnetic separators and other sorting mechanisms are employed to ensure high purity in the recovered materials.

-

Wind Turbine Blade Recycling Machine

Our Wind Turbine Blade Recycling Machine is designed for the safe and efficient processing of decommissioned wind turbine blades. By combining cutting, shredding, and separation technologies, the system breaks down composite materials into manageable fractions, enabling the recovery of valuable components such as glass fibers and resins.

-

Waste Tire Recycling Machine

Our Waste Tire Recycling Machine is designed for the efficient processing of end-of-life tires, turning them into valuable raw materials like rubber crumb, steel wire, and textile fibers. The system utilizes a multi-stage process, including shredding, granulation, and advanced separation technologies, to break down tires and separate the rubber from the steel and textiles.

-

Lead-Acid Battery Recycling Plant

The Lead-Acid Battery Recycling Plant uses advanced crushing, separation, and smelting technologies to recover valuable materials such as lead, plastics, and sulfuric acid. The purified lead is reused in new batteries or other industries, while sulfuric acid is neutralized for safe disposal or converted into usable products.

-

Copper and Aluminum Radiator Recycling Plant

The Copper and Aluminum Radiator Recycling Plant is a specialized system designed to efficiently separate and recover valuable metals, such as copper and aluminum, from discarded radiators found in vehicles and industrial equipment. The plant employs advanced techniques, including shredding, magnetic separation, and air classification, to break down the radiators and separate the metals for recycling.

-

Automotive Shredder Residue Recycling Line

The Automotive Shredder Residue (ASR) Recycling Line is an advanced sorting system designed to process the complex residue left after shredding end-of-life vehicles, household appliances, and other scrap metals.

-

Municipal Solid Waste Recycling Line

The line combines multiple processes, including shredding, trommel screening, magnetic separation, air classification, and manual or automated sorting, to extract reusable resources such as plastics, metals, wood, bricks, and organic matter.

-

Scrap Metal Shredding Crushing Sorting Line

The Scrap Metal Shredding, Crushing, and Sorting Line is designed for the efficient recycling of ferrous metals, non-ferrous metals, and non-metallic materials through shredding, crushing, and separation processes.

-

Toner Cartridge Recycling Machine

The Toner Cartridge / Drum Unit Printer Recycling Machine is a fully automatic system designed for the safe and efficient recycling of waste printer consumables.

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export