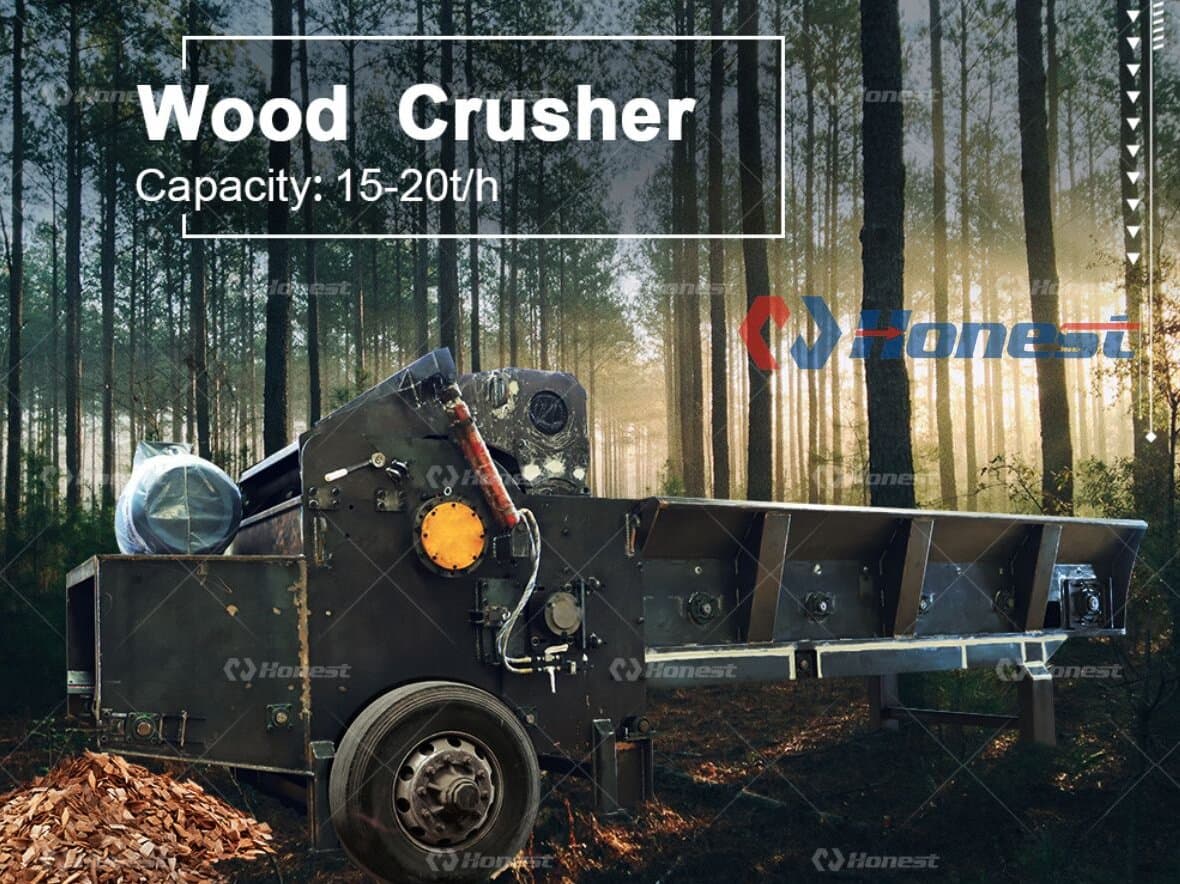

Equipment Features

Main Applications: Designed for efficient size reduction of various wood materials

Raw Materials:All kinds of wood materials

Main Final Products:Wood chips, sawdust, wood powder, biomass material

If you want to start your recycling business, feel free to contact us.

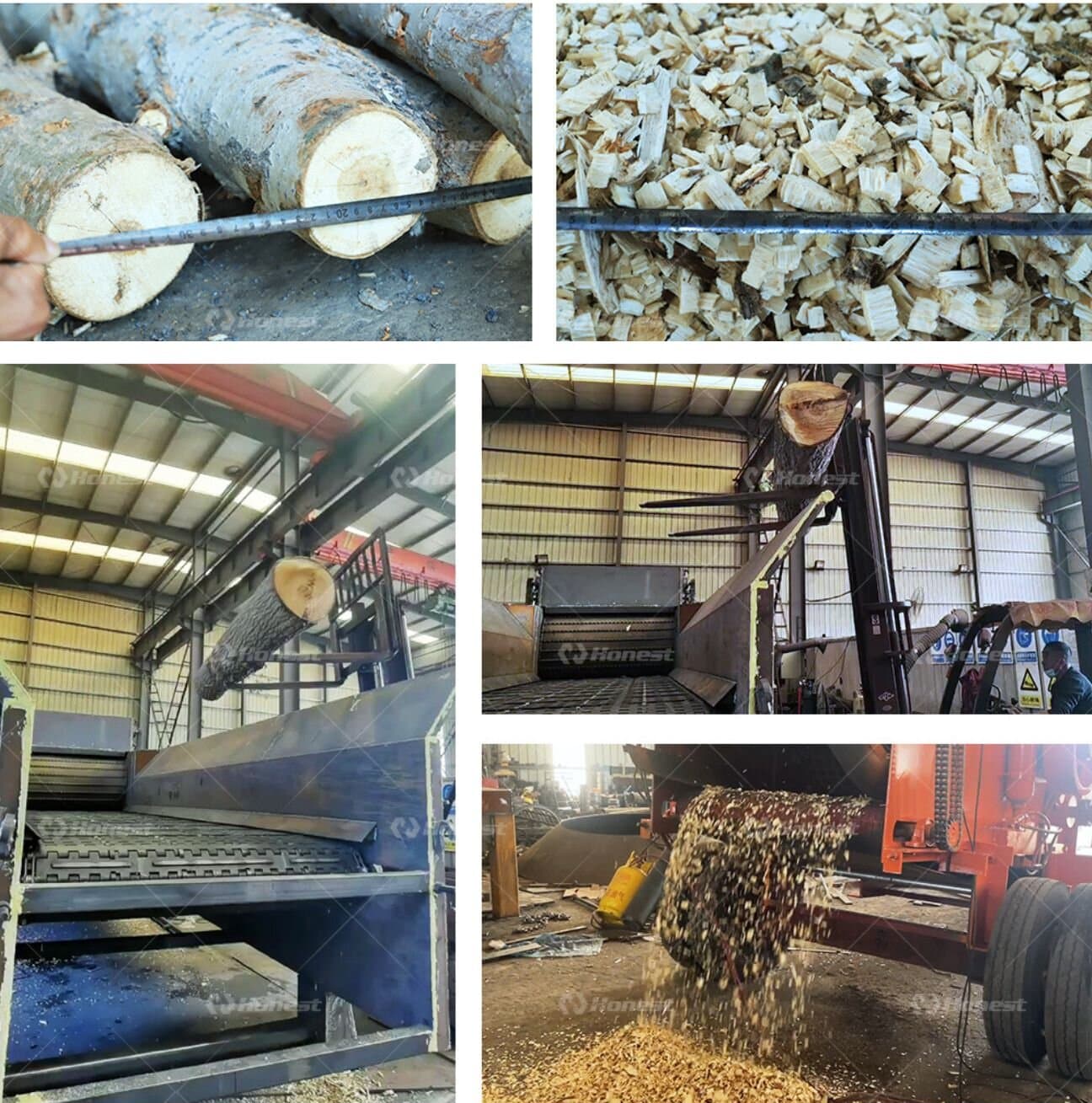

The Wood Chipper Machine can process a wide variety of raw materials, making it highly versatile.

Wood Chipper/Crusher Machine Product Usage /Application:

It can handle different types of wood materials such as logs, branches, tree stumps, wood with nails, construction templates, wooden pallets, round wood cores, slats, boards, wooden brackets, waste furniture, doors, windows, and even wood from house demolition. In addition, it is also suitable for non-wood biomass materials including straw, bulk straw, reed, cotton stalks, sugarcane, palm trees, and bamboo.

This wide processing capability makes it ideal for use in biomass energy production, recycling, and waste management applications.

Technical Parameters

| 1. Feed System | Trough Chain Conveyor |

| Type | Chain Feed |

| Motor Power | 11Kw+7.5Kw |

| Width | 1400mm |

| Delivery Length | 5000mm |

| Speed | 0-26m/min Adjustable |

| Chain Plate Material | 16Mn |

| 2. Broken Body System | Comprehensive Crusher |

| Knife Roll Diameter | 800mm |

| Knife Roller Speed | 570 turn/minute |

| Production Capacity | 15-20t/h |

| Feed Size | 1400*600 |

| Number Of Blades | 3 groups of 6 pieces |

| Blade Material | 55SiCr |

| Main Motor Power | 200Kw |

| Finished Material Particle Size | 30-50mm |

Key components of Wood Chipper/Crusher Machine

The machine features a sturdy structure, high-speed rotor, and optional blade or hammer configurations to meet different needs. It supports both stationary and mobile setups with options like tires or tracks. During operation, high-strength blades on the rotating cutter roller crush material through cutting, grinding, and impact.

Wood Chipper/Crusher Machine Advantages Description:

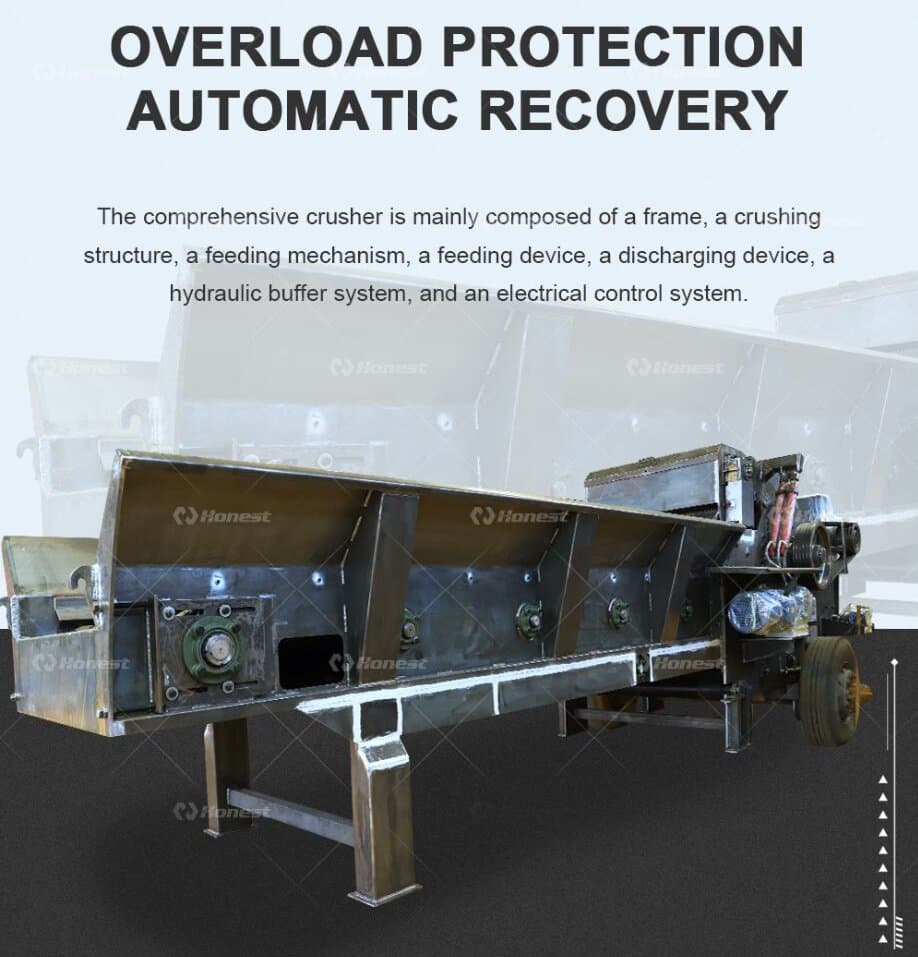

The comprehensive crusher is mainly composed of a frame, a crushing structure, a feeding mechanism, a feeding device, a discharging device, a hydraulic buffer system, and an electrical control system.

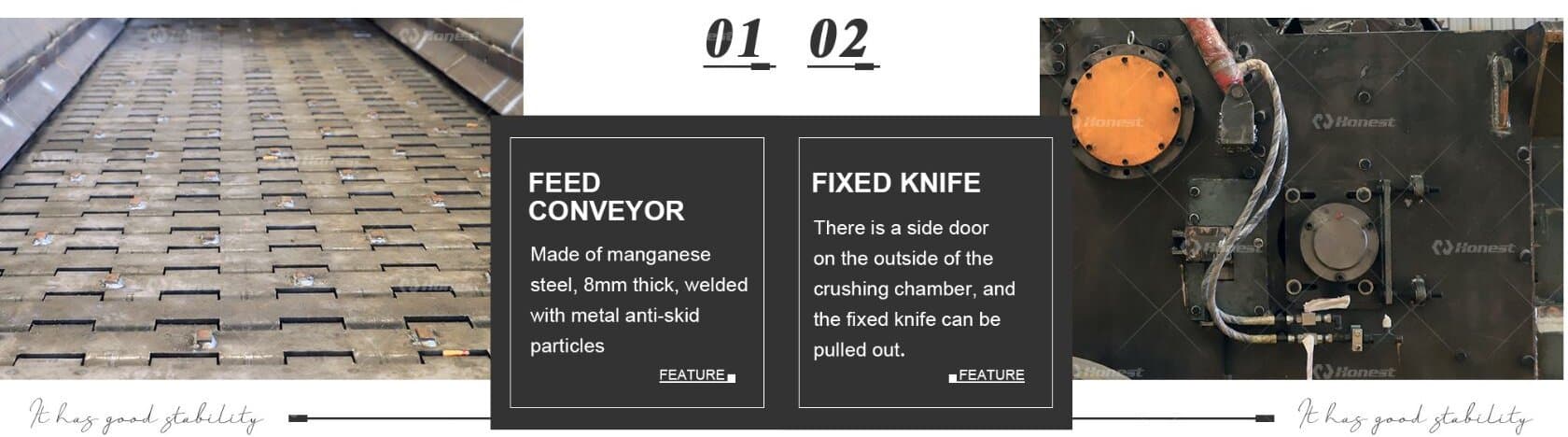

FEED CONVEYOR : Made of manganese steel, 8mm thick, welded with metal anti-skid particles

FIXED KNIFE : There is a side door on the outside of the crushing chamber, and the fixed knife can be pulled out.

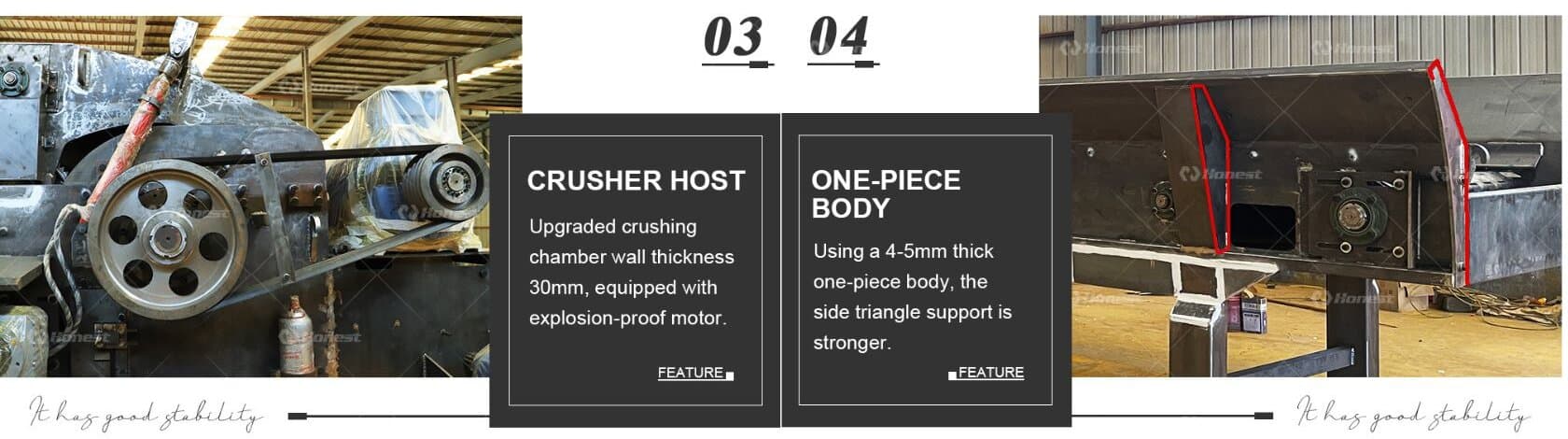

CRUSHER HOST : Upgraded crushing chamber wall thickness 30 mm, equipped with explosion-proof motor.

ONE-PIECE BODY : Using a 4-5mm thick one-piece body, the side triangle support is stronger.

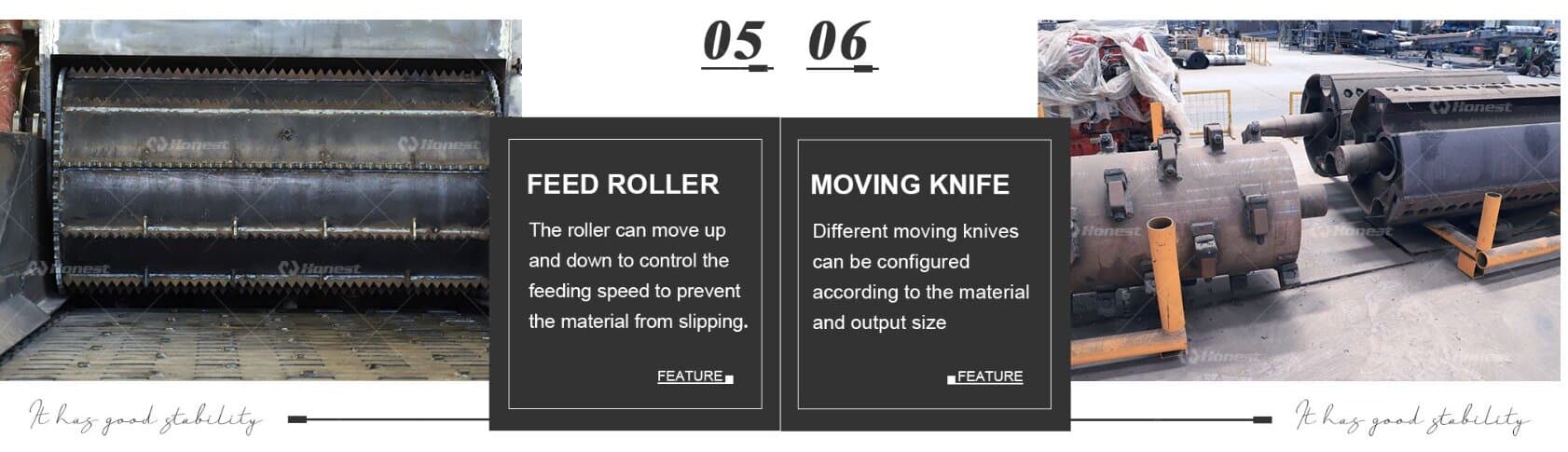

FEED ROLLER : The roller can move up and down to control the feeding speed and prevent the material from slipping.

MOVING KNIFE : Different moving knives can be configured according to the material output size.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export