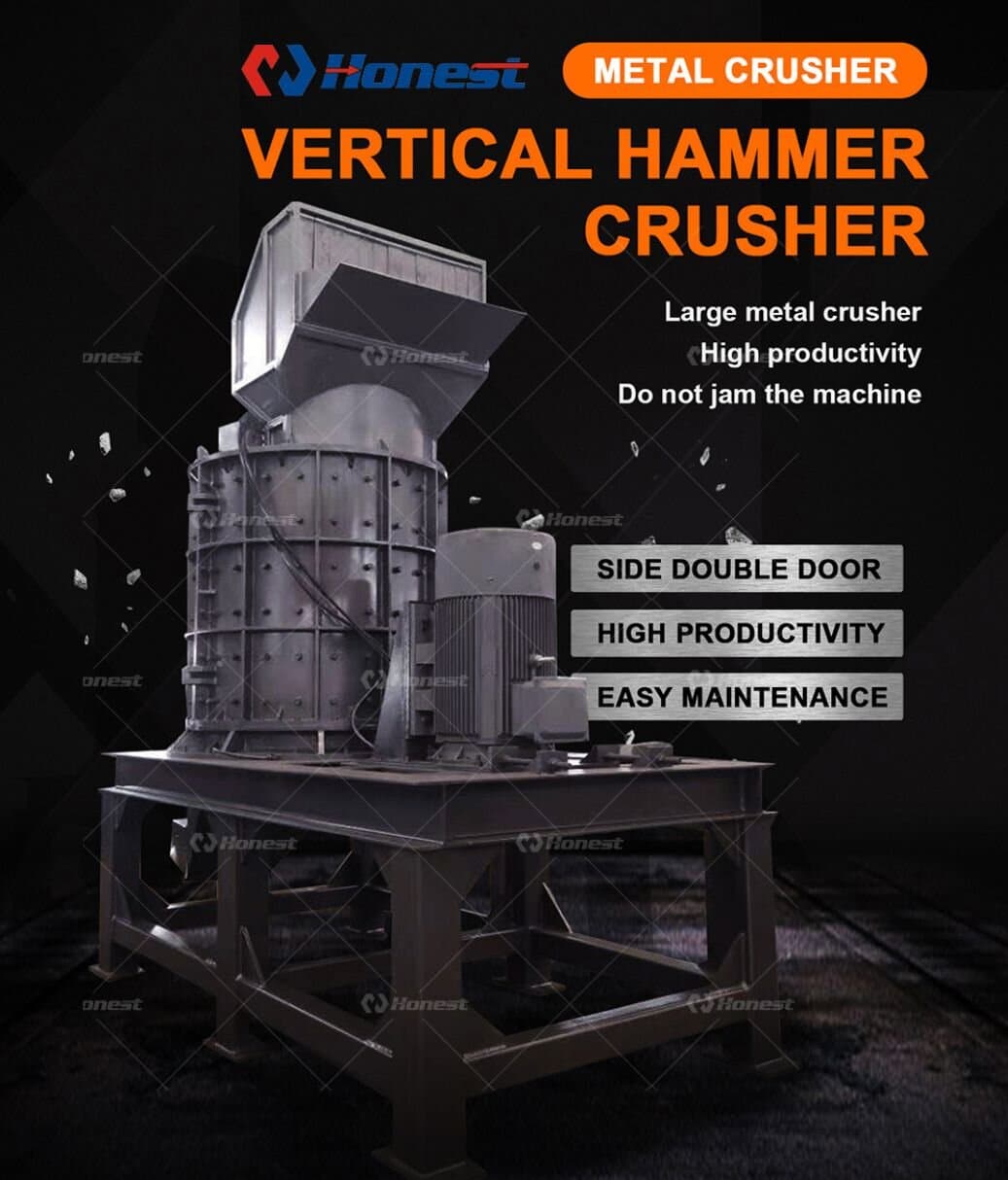

Equipment Features

Main Applications:Crush various wastes into small pieces

Raw Materials:scrap metal, aluminum profile, motor stator, rotor and other waste mixed metal materials

Main Final Products:lron,Other materials

If you want to start your recycling business, feel free to contact us.

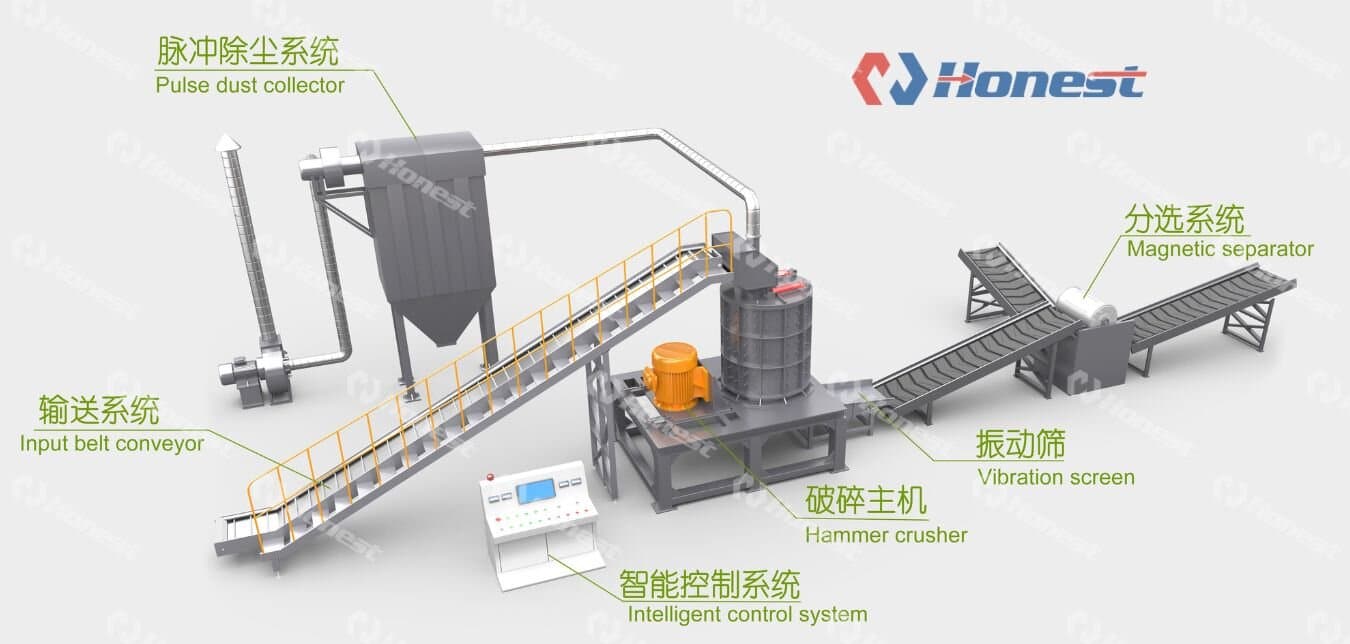

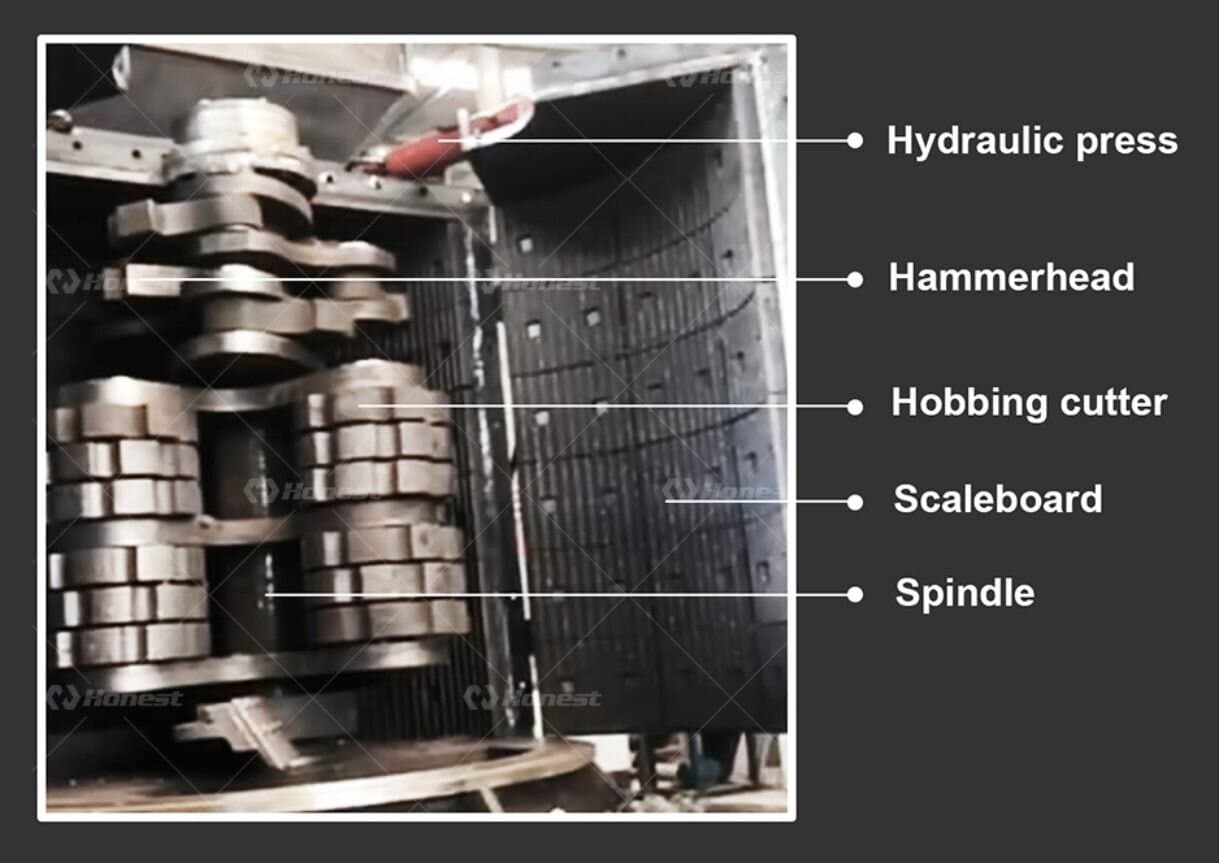

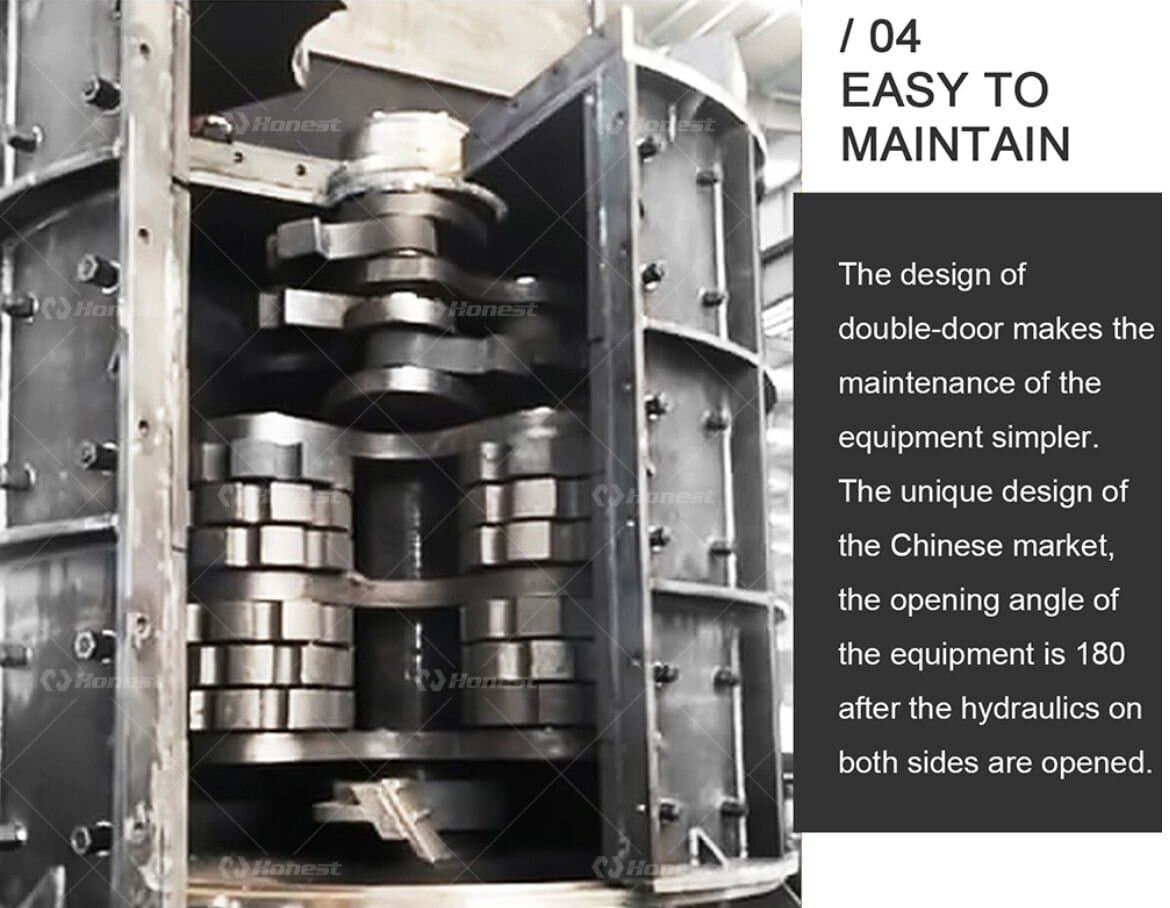

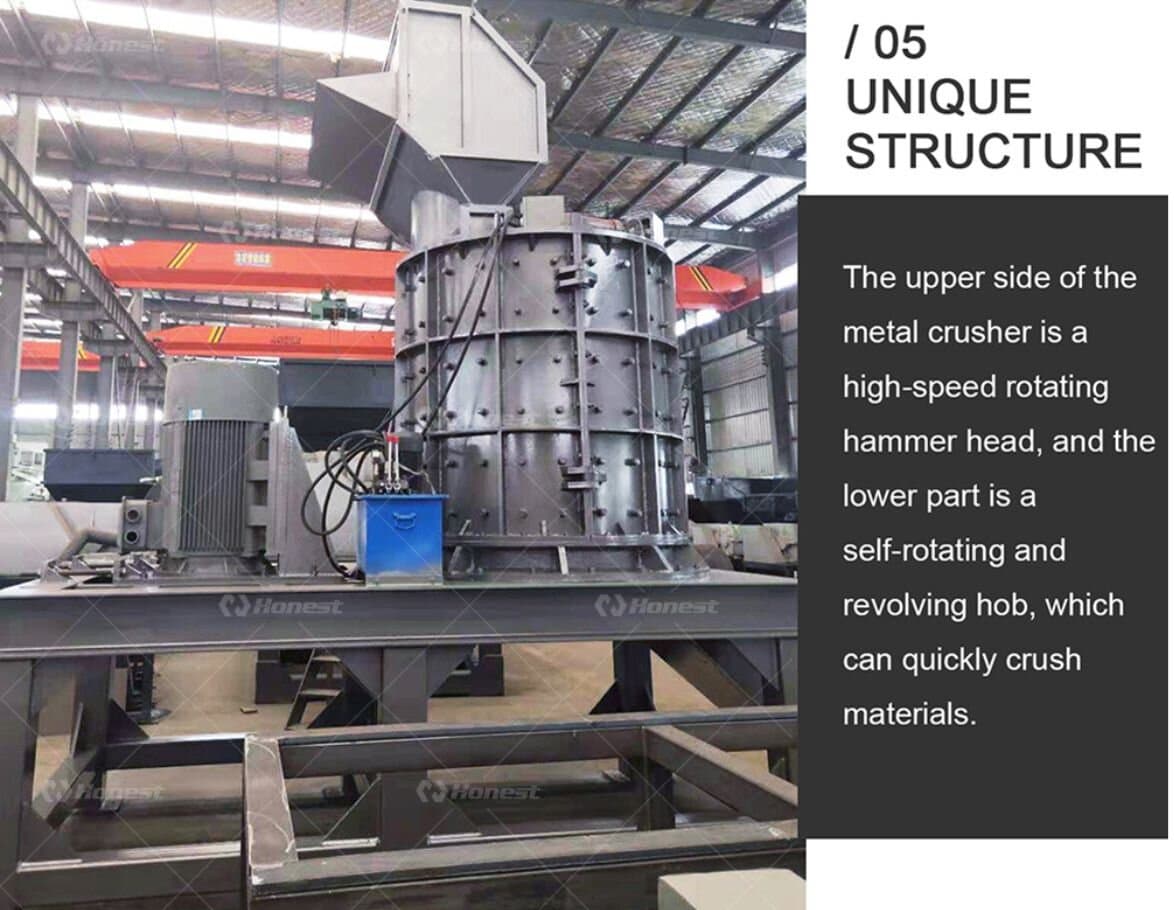

Vertical Hammer Crusher is an impact crusher that utilizes a vertical rotor with oscillating hammers to crush materials. It is used in a wide range of industries for its efficiency in reducing the size of brittle and moderately hard materials. The heart of a vertical hammer crusher is the vertical rotor that rotates at high speed. The hammers are attached to the rotor and oscillate freely or rigidly. As the rotor rotates, the hammers strike the material, hitting it against an impact or crushing plate. The impact force and the speed of the rotor determine the crushing efficiency. The crushing chamber is designed to contain the material and facilitate the crushing process. The impact and crushing plates are strategically placed to maximize impact force. A grid or screen at the bottom of the crusher controls the output particle size. Material is crushed until it is small enough to pass through the grate opening. Material is fed from the top of the machine. It is driven by an electric motor.

Raw Material

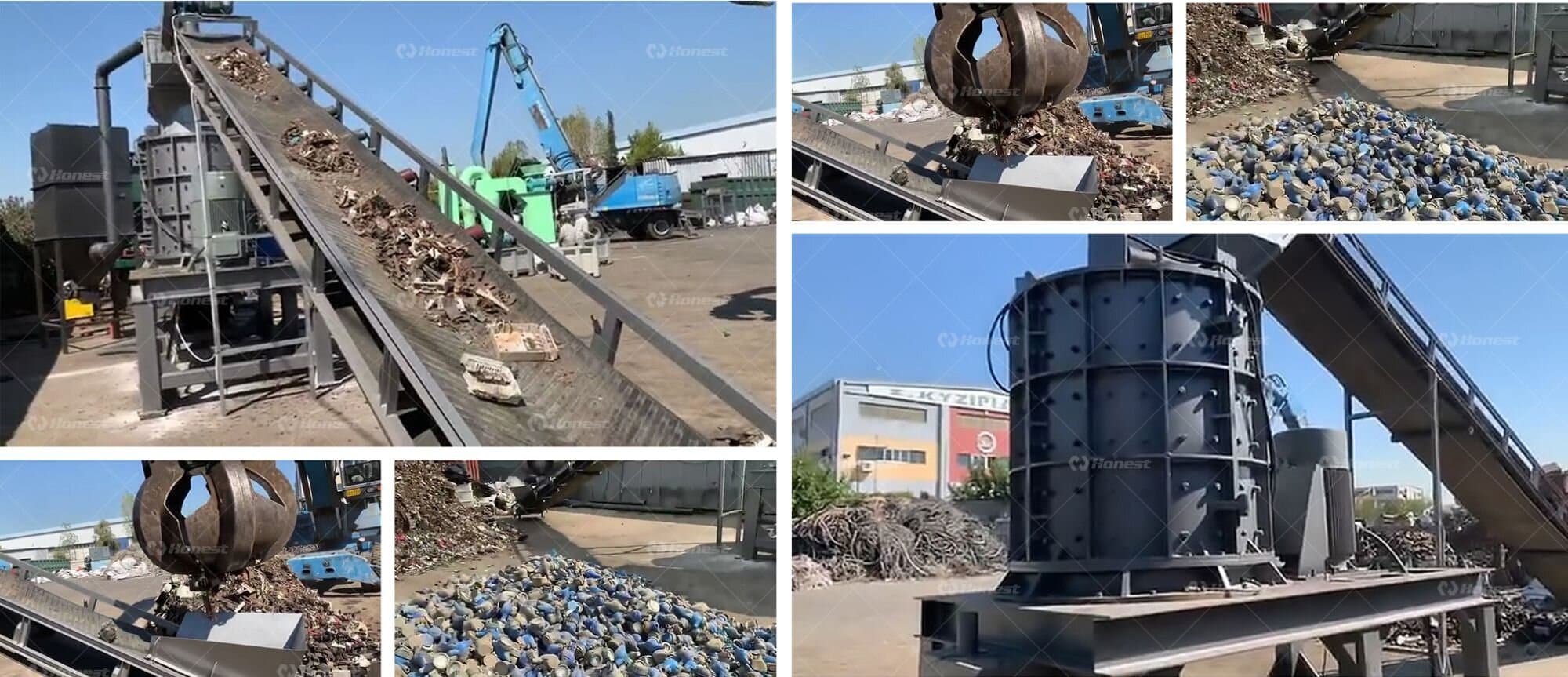

The main application materials are: scrap metal, aluminum profile, motor stator, rotor and other waste mixed metal materials.

Final Products

After crushing, most large plastics or other materials will be reduced in size by up to 30%, with some materials up to 50% in size after crushing.

Technical Parameters

| Model | HN-VHC-1000 | HN-VHC-1200 | HN-VHC-1500 |

| Capacity(kg/h) | 800-1000 | 1500-2000 | 2000-3000 |

| Power(kw) | 75kw*2 | 90kw*2 | 132kw*2 |

| Spindle speed(rpm) | 650 | 650 | 672 |

| Rotating diameter(m) | 1.0 | 1.5 | 1.5 |

| Number of hammers | 2pcs | 4pcs | 2pcs |

| Unit weight of hammer head | 20kg | 25kg | 30kg |

| Number of Hobs | 36pcs | 36pcs | 36pcs |

| Unit weight of hob | 40kg | 40kg | 42kg |

| Kicking device | Active type | ||

| Power of hydraulic station | 2.2kw | 2.2kw | 2.2kw |

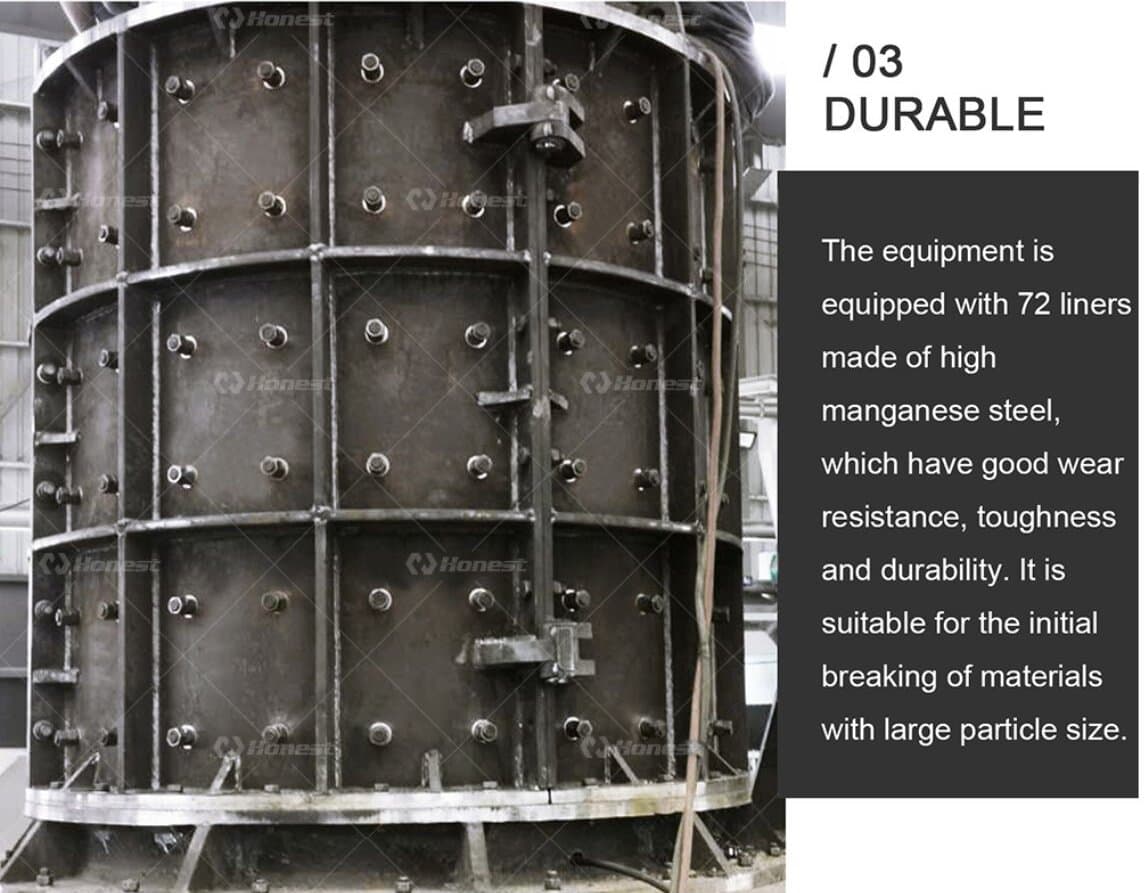

| Hammer head material | High manganese alloy steel | ||

| Equipment weight(tons) | 9t | 12t | 18t |

| Equipment size(m) | 1.2×1.2×3 | 1.5×1.5×3.2 | 1.8×1.8×3.5 |

Vertical Hammer Crusher Machine Brief Introduction

The vertical metal crusher mainly uses the upper hammer structure to break materials by rotating at high speed. In the process of material automatic falling, the material is finely crushed and rolled by the gap between the lower hob and the crushing cavity. Meet the discharge requirements. Vertical crusher is characterized by its structure, high crushing speed, high efficiency and easy maintenance.The discharge belt is connected with magnetic separation, which can directlyseparate and fit other materials

Vertical Hammer Crusher Working Principle

Customers Site Overview

Our vertical metal broken gold is sold to many countries and regions around the world. Get unanimous praise from customers. If you want to get accurate equipment configuration and recycling plan acording to your own materials and output, please contact us directly.

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export