Equipment Features

Main Applications:Separates steel wire from waste tires

Raw Materials:Passenger car tires, truck tires (excluding OTR tires)

Main Final Products:Clean scrap steel wire (directly recyclable or salable), separated rubber tire (for further processing).

If you want to start your recycling business, feel free to contact us.

Our Tire Steel Wire Drawing Machine is a high-efficiency, environmentally friendly device designed specifically for waste tire recycling. It is used to quickly and thoroughly extract the tough steel wires embedded in tire sidewalls, preparing the tires for the next stage of processing.

Application / Working Principle of Tire Steel Wire Drawing Machine:

The waste tire is placed into the machine’s inlet, where a hydraulic-powered or mechanically driven traction system firmly grips the inner steel bead or body wires. Once activated, the device applies a strong pulling force to extract the steel wires from the rubber structure.

Thanks to the physical difference between steel and rubber, the wires are clean and completely separated without significant damage to the surrounding rubber. During this process, the extractor’s hook engages the steel inside the tire, and under the tension of the hydraulic cylinder, the wire is pulled out as a whole. Simultaneously, the pulling mechanism slightly tears open the tire sidewall, further assisting in the separation.

This ensures efficient, clean removal of steel components, leaving the rubber intact for subsequent shredding, grinding, or reuse.

Technical Parameters

| Model | HN-LS-1200 |

| Power | 11 Kw |

| Max.Tire Diameter | 1200 mm |

| Weight | 2000 Kg |

| Dimensions L*W*H | 4100*1300*1750 mm |

| Working voltage:380±10V(415V, 440V also can be customized); | |

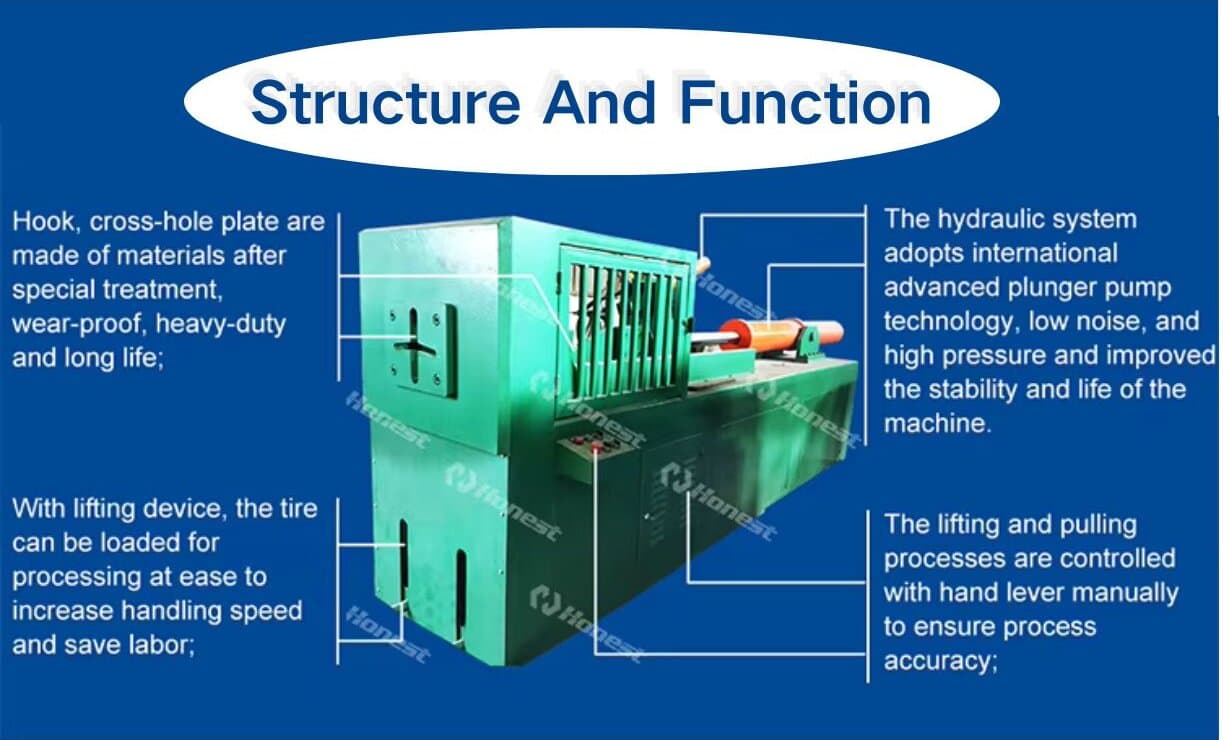

Key components of Steel Wire Drawing Machine

Steel wire drawing machine is composed of motor, hydraulic system, steel wire retractor, pull mouth, body , etc.

Hook and cross-hole plates made of materials after special treatment,wear-proof, heavy-duty, and long life;

The hydraulic system adopts international advanced plunger technology, low noise, and high pressure, and the stability and life of the machine;

With a lifting device, the tire can be loaded for processing at ease to increase handling speed and save labor;

The lifting and pulling processes are controlled with a hand lever manually to ensure process accuracy;

FAQ – Waste Tire Steel Wire Separator

Q: What types of tires can this machine process?

A: It is suitable for car and truck tires with a diameter up to 1300mm.

Q: Can it process OTR (Off-the-Road) tires?

A: No. For OTR tires, please use a tire bead cutting machine.

Q: How is the machine installed?

A: We provide wiring diagrams and remote technical support. Normally, installation can be done by yourself. On-site support is available if needed.

Q: Do you provide spare parts?

A: Yes, spare parts are available at cost price. A spare parts list will be provided with the machine.

Q: Will the machine be tested before delivery?

A: Yes, all machines are tested before shipment. We will send you testing videos, or you can inspect the machine on-site.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export