Equipment Features

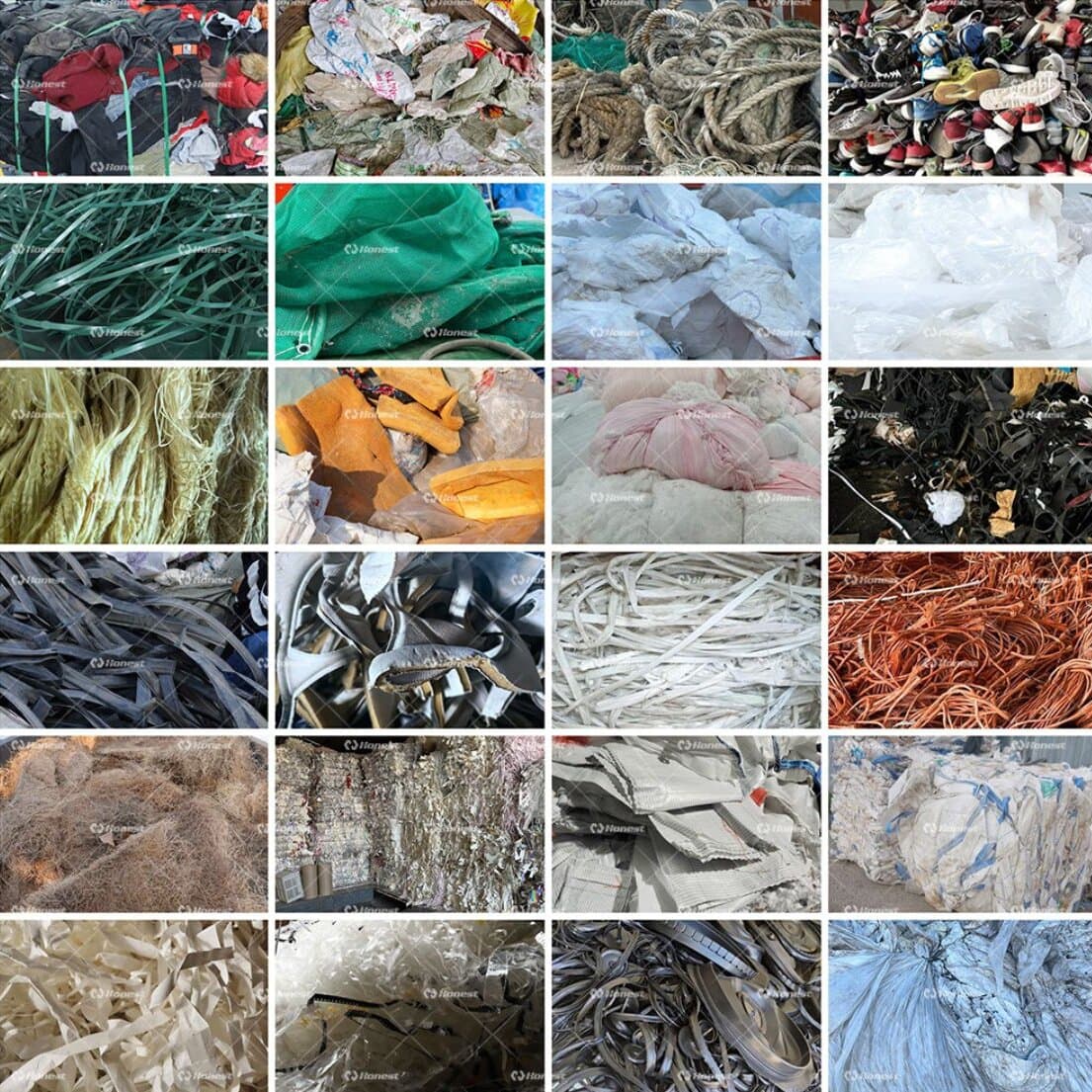

Main Applications:Used for recycling textiles, plastic packaging, and agricultural films.

Raw Materials:Handles soft materials like clothes, woven bags, films, straps, and nets.

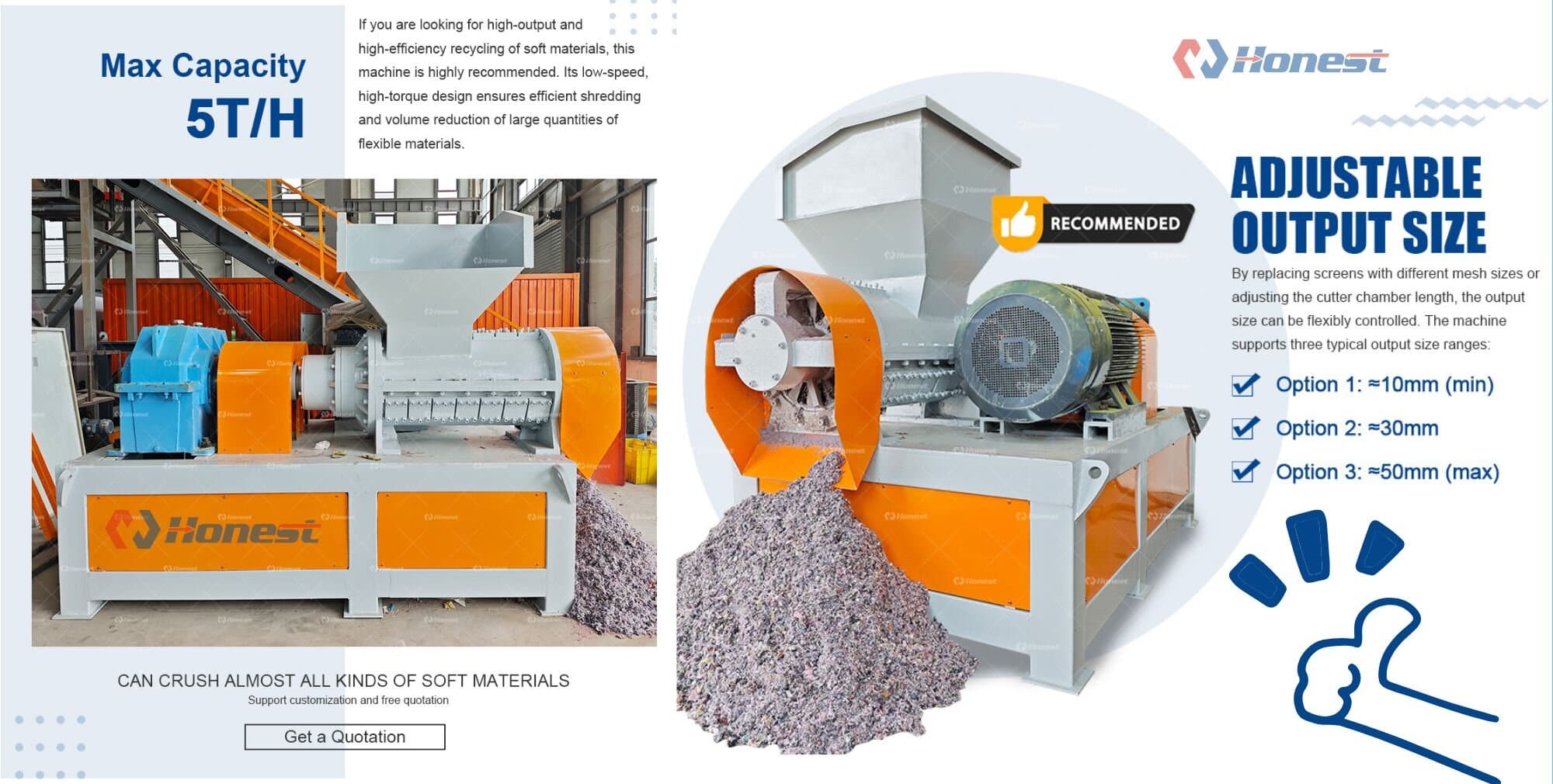

Main Final Products:Produces 10–50mm shredded pieces

If you want to start your recycling business, feel free to contact us.

This spiral shredder is widely used in textile recycling, plastic packaging recovery, agricultural film disposal, and pre-treatment of soft waste before granulation or washing. It is especially suitable for reducing volume and improving transport or storage efficiency.

Spiral Shredder Machine Product Usage / Application:

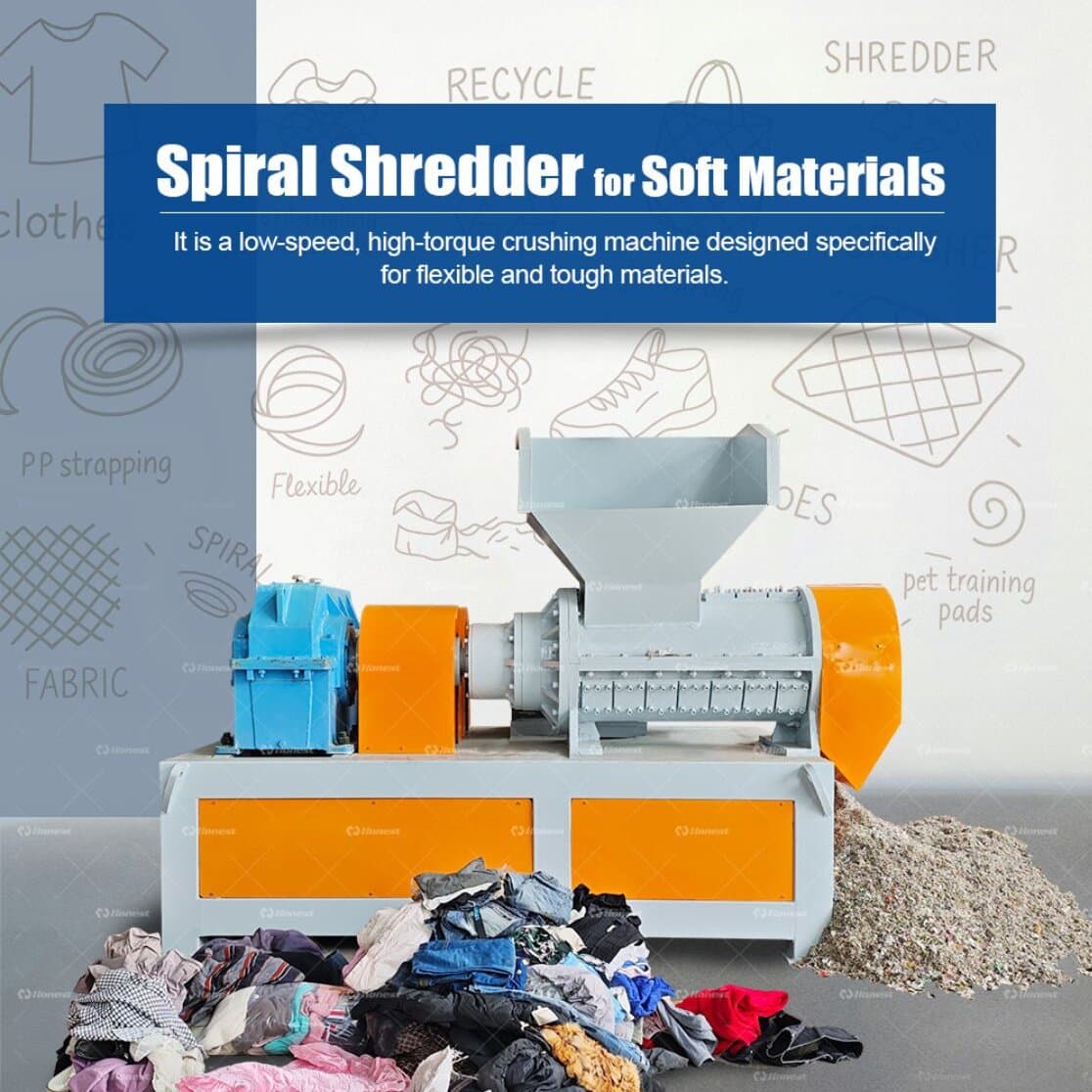

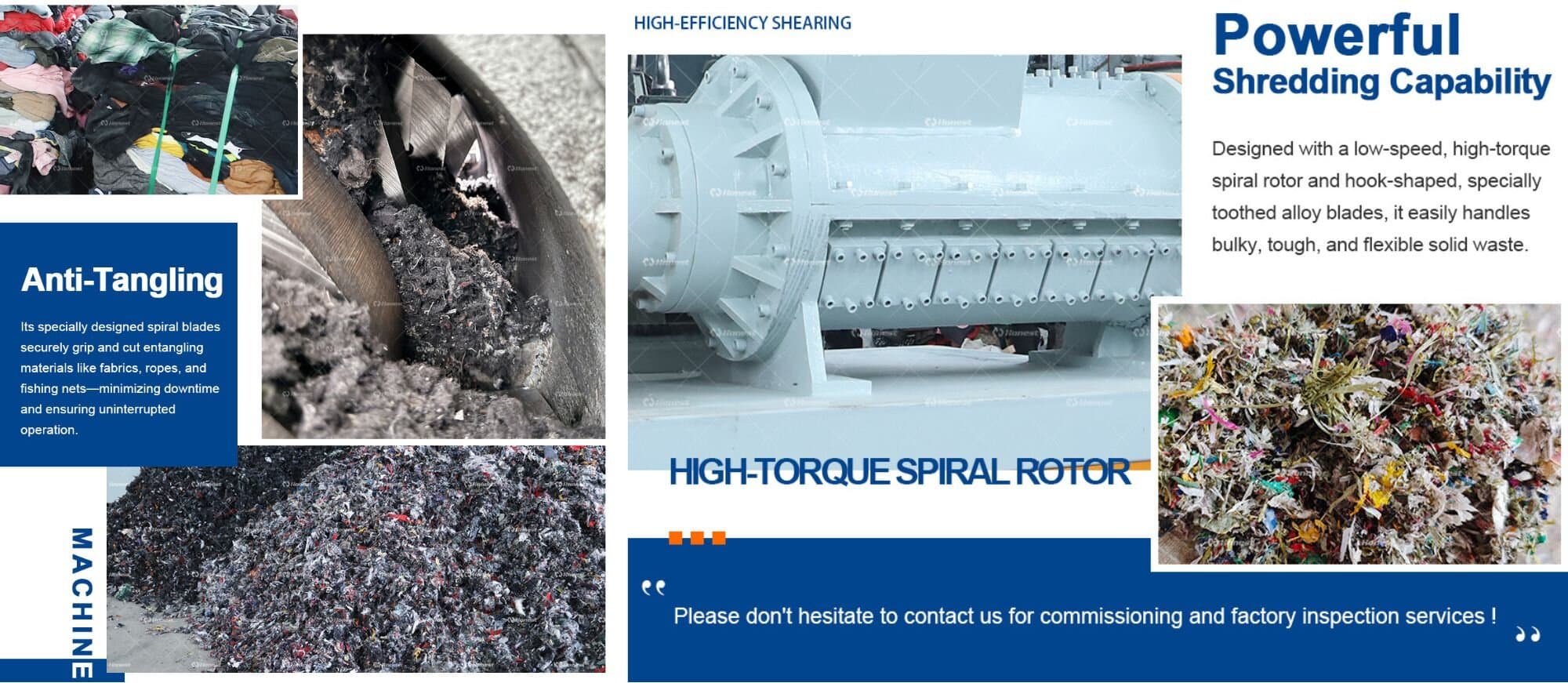

The Spiral Shredder for Soft Materials is a highly efficient cutting solution specifically designed for processing flexible solid waste.

With its low-speed, high-torque spiral blade design, this machine excels at shredding fibrous, fabric-based, tough, and easily entangled materials. It is ideal for processing a wide variety of soft waste, including used clothing, woven bulk bags, agricultural film, PP straps, pet pads, and various flexible plastic packaging materials. Whether for pre-treatment in recycling processes or volume reduction to cut transportation costs. This shredder delivers reliable and efficient performance, making it an excellent choice for applications such as textile recycling, plastic packaging recovery, and agricultural film disposal.

Technical Parameters

| Model | Model Specification | Power | Gearbox Model | Capacity |

|---|---|---|---|---|

| Model 1 | HN-LXFS-300 | 45KW-6 | ZSY-250 | 200–400 kg/h |

| Model 2 | HN-LXFS-350 | 55KW-6 | ZSY-280 | 400–600 kg/h |

| Model 3 | HN-LXFS-450 | 90KW-6 | ZSY-315 | 1–1.5 t/h |

| Model 4 | HN-LXFS-550 | 110KW-6 | ZSY-355 | 2–3 t/h |

| Model 5 | HN-LXFS-650 | 160KW-6 | ZSY-450 | 3–4 t/h |

| Model 6 | HN-LXFS-850 | 250KW-6 | ZSY-560 | 4–5 t/h |

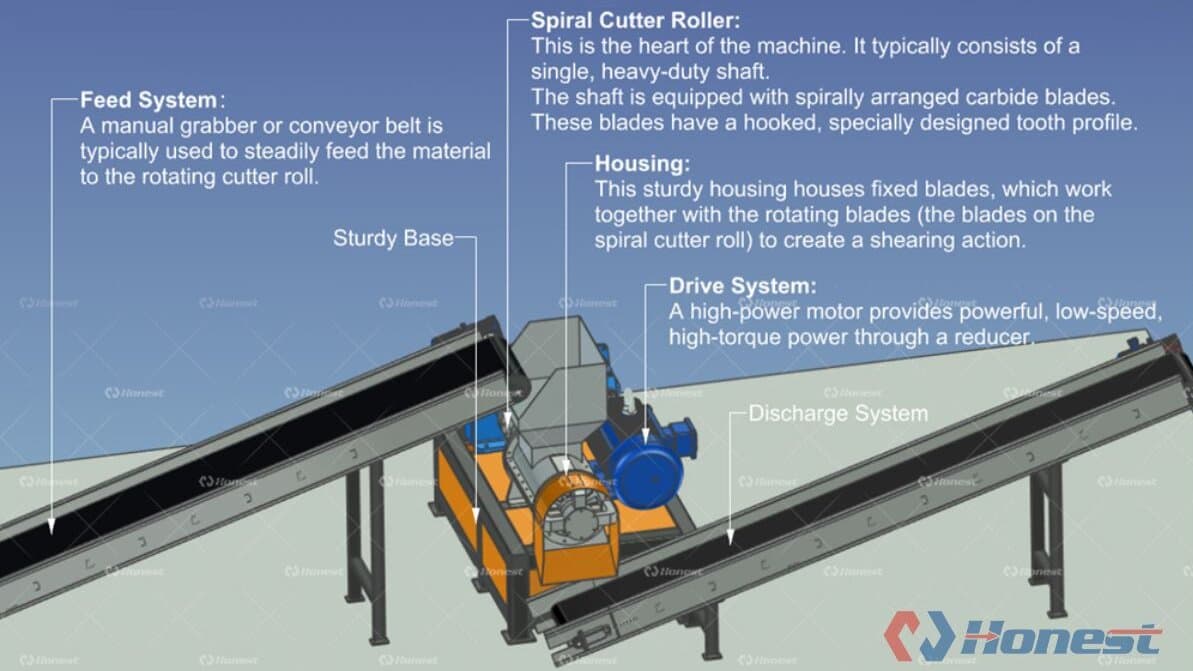

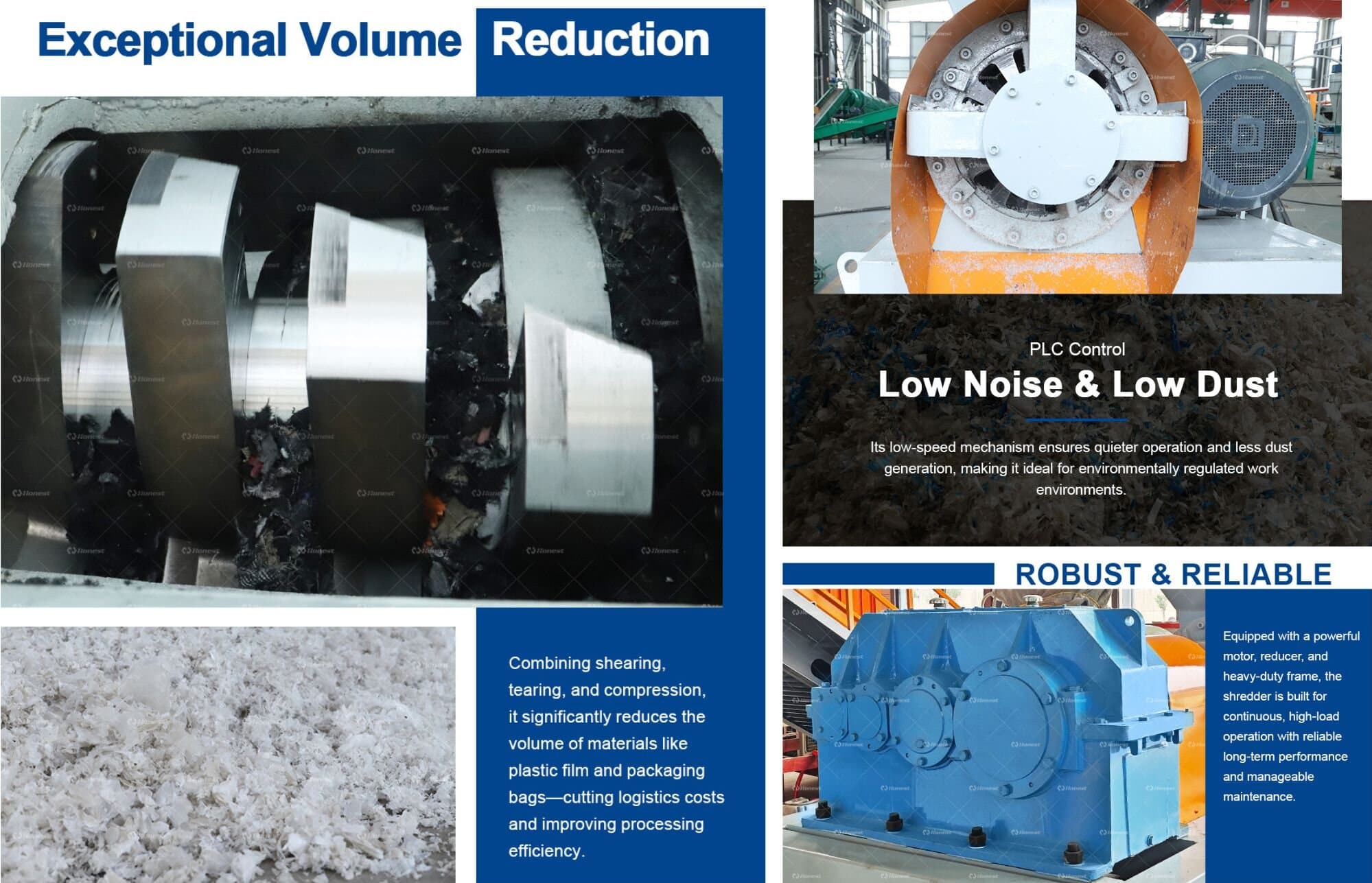

Product Structure Spiral Shredder Machine

Our equipment features a robust and efficient design, combining high cutting performance with long-term durability. Material is steadily fed into the machine through a manual grabber or conveyor belt, ensuring continuous and controlled input. At the core of the system is the spiral cutter roller, a heavy-duty shaft fitted with spirally arranged carbide blades. These uniquely hooked and tooth-profiled blades work in tandem with the fixed blades mounted inside the sturdy housing, creating a powerful and precise shearing action. Driven by a high-torque, low-speed motor system through a heavy-duty reducer, the machine delivers consistent force even under tough working conditions. After processing, materials are efficiently transferred out via the discharge system, completing the cycle of safe and efficient operation. This structure makes the equipment ideal for demanding recycling and reduction applications.

Key components of Spiral Shredder Machine

The machine adopts a spiral cutter roller structure, consisting of a single heavy-duty shaft equipped with hook-shaped carbide blades arranged spirally. As the materials are fed into the cutting chamber—via a conveyor or mechanical grabber—the rotating spiral roller works in tandem with fixed blades housed within the frame, generating a powerful shearing action. This design allows for effective tearing, shearing, and compression of materials, achieving significant volume reduction while preventing tangling and jamming issues common with soft or fibrous waste. The anti-entanglement properties make the shredder especially valuable in textile, film, and packaging recycling applications.

Output size can be flexibly adjusted by replacing screen meshes or modifying the length of the cutting chamber. The machine supports three typical output size ranges: ≤10mm for fine processing, around 30mm for standard applications, and up to 50mm for coarse shredding. This adjustability makes it highly versatile for both pre-treatment and final reduction tasks in a production line.

Driven by a high-power motor and reducer, the shredder offers strong torque at low speeds, enabling stable operation under heavy loads while maintaining low energy consumption. The entire system is controlled by an intelligent PLC system, ensuring automated protection, real-time monitoring, and ease of maintenance. Its slow rotation also results in lower noise levels and minimal dust generation, making it suitable for environmentally regulated workspaces.

Built with a robust frame and wear-resistant components, the Spiral Shredder is designed for long-term, continuous-duty operation. Whether the goal is to improve material handling efficiency, reduce logistics and storage costs, or prepare soft waste for downstream recycling, this machine provides a dependable and effective solution.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export