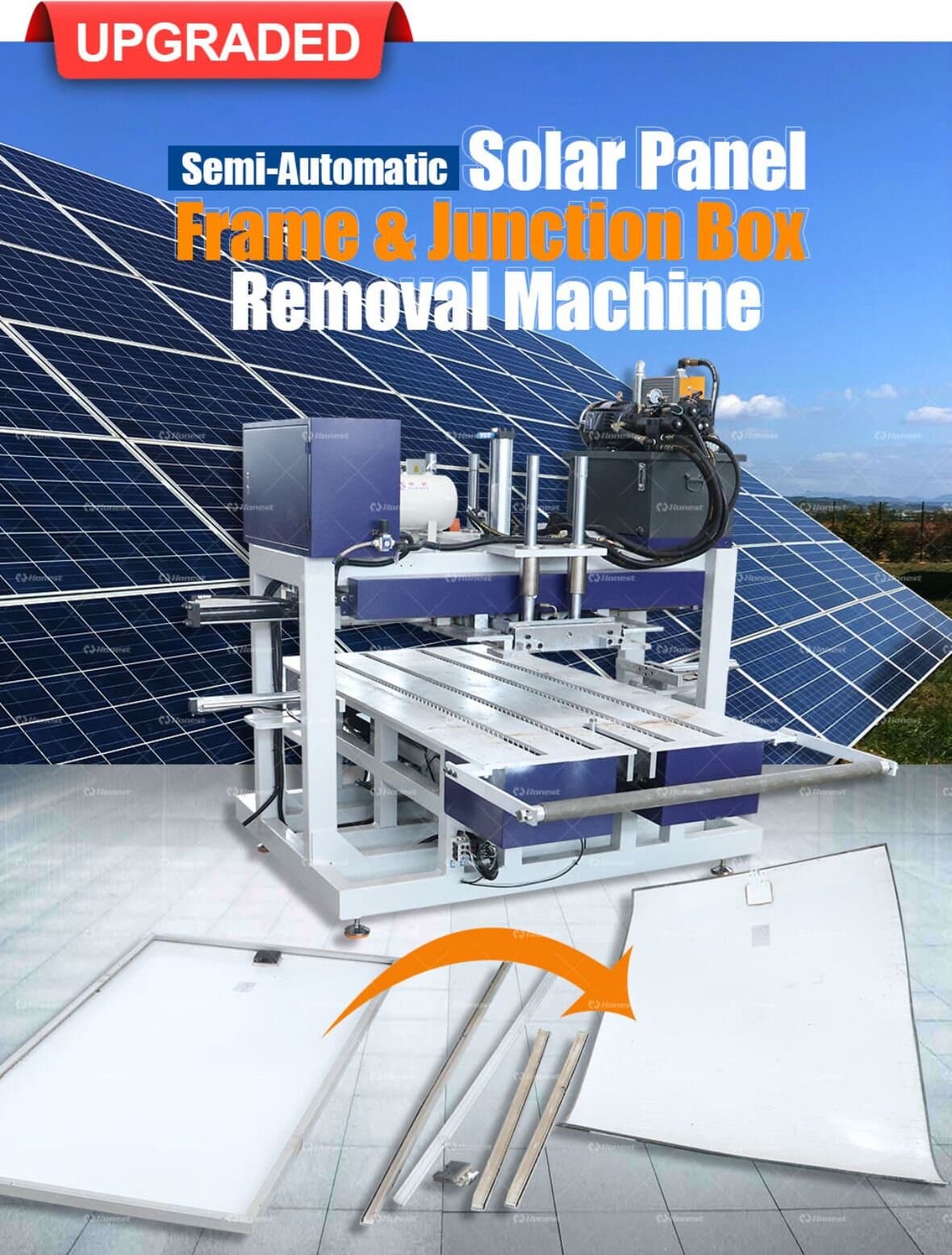

Equipment Features

Main Applications:Used to remove metal aluminum frame and J-Box from Solar Panels

Raw Materials:Waste Solar PV Panels,Photovoltaic panels

Main Final Products:metal aluminum frame and J-Box

If you want to start your recycling business, feel free to contact us.

Semi-Automatic Aluminum Frame Removing Machine is the pre-processing equipment of Solar PV Panels Recycling Line, which is mainly used to remove the frames of solar panels. Usually, a combination of multiple technologies is used to achieve the removal of the frame. Mechanical or hydraulic structures can quickly remove the aluminum alloy frames around the photovoltaic panels. Avoid the tedious process of manual disassembly, reduce human losses, and ensure the complete recycling of frame materials. And it is suitable for photovoltaic modules of different sizes and brands, without frequent equipment adjustments.

Raw Material

The machine is mainly used to dismantle the aluminum alloy frames of waste or scrapped photovoltaic panels, and is suitable for retired modules from photovoltaic power stations or rooftop solar systems. Its main raw material is solar panels with aluminum alloy frames.

Final Products

Aluminum frame is product of frame removing machine, the purity is 100%.

Technical Parameters

| Item | Specification/Description |

| Production Capacity | 1-2 pieces per minute |

| Overall Dimensions | 2850mm x 2750mm x 2050mm |

| Power | 3.75KW + 1.5KW |

| Max Processing size | 2380mm x 1300mm x 35mm |

| Min Processing size | 1580mm x 808mm x 40mm |

| Machine Weight | 2 tons |

Key components of Semi-Automatic Aluminum Frame Removing Machine

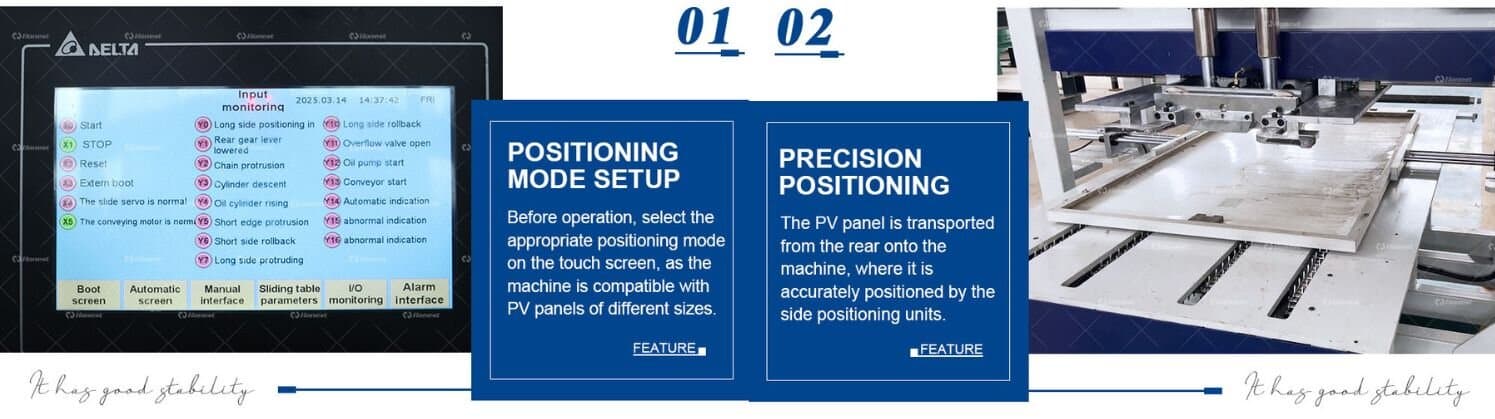

The Semi-Automatic Aluminum Frame Removing Machine consists of a hydraulic station, frame separation unit, junction box removal unit, short-side and long-side positioning units, conveyor, drive motor, base frame, machine feet, and an electrical cabinet with a PLC touch screen, all working together to ensure efficient and precise removal of aluminum frames and junction boxes from solar panels.

POSITIONINGMODE SETUP : Before the operation, select the appropriate positioning mode on the touch screen, as the machine is compatible with PV panels of different sizes.

PRECISION POSITIONING : The PV panel is transported from the rear onto the machine, where it is accurately positioned by the side positioning units.

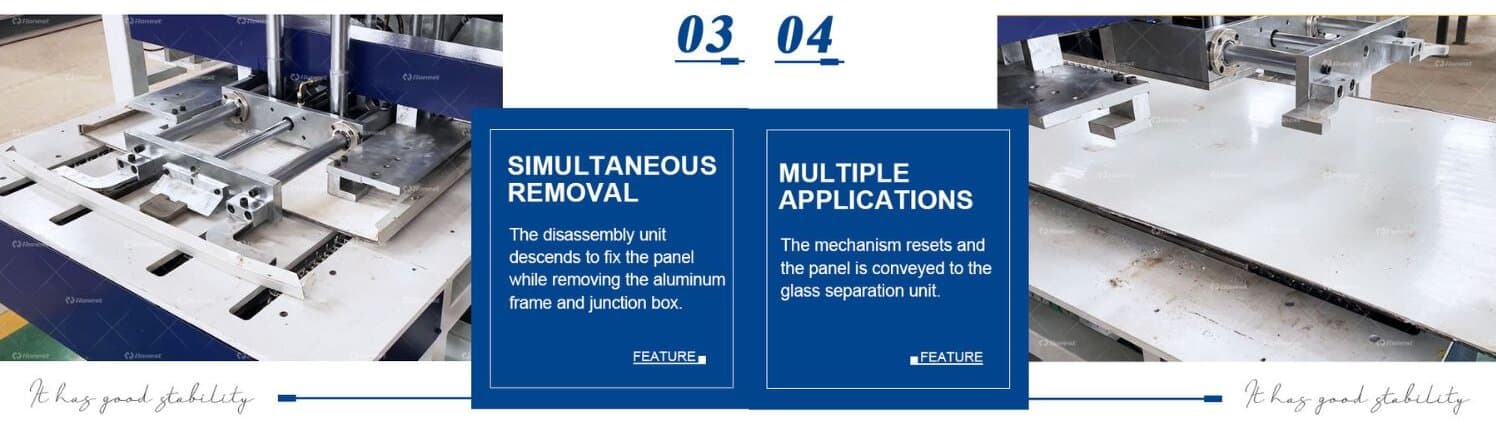

SIMULTANEOUS REMOVAL : The disassembly unit descends to fix the panel while removing the aluminum frame and junction box.

MULTIPLE APPLICATIONS : The mechanism resets and the panel is conveyed to the glass separation unit.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export