Equipment Features

Main Applications:Recycling copper from scrap motor stators.

Raw Materials:Motor stators from various household appliances.

Main Final Products:Clean copper wire and steel/iron.

If you want to start your recycling business, feel free to contact us.

Motor Stator Dismantling Machine integrates three functions in one: cutting copper wire, retrieving copper wire from small stators, and extracting copper wire from large stators, making copper extraction fast, efficient, and energy-saving.

Motor Stator Copper Cutting and Extracting Machine Product Usage / Application:

Designed for recycling copper from motor stators found in various household appliances: Refrigerators, cold drink machines, air conditioners, fans, dehumidifiers, washing machines, electric irons, dust collectors, cookers, ovens, hair dryers, TVs, radios, and more.

Technical Parameters

| Model | HN-ZT-3 |

| Power | 4 kW |

| Weight | 480 kg |

| Overall Dimensions | 2.6 × 1.1 × 1.2 m |

| Process range: Stator inner size > 50 mm, diameter < 500 mm | |

Product Structure Motor Stator Copper Cutting and Extracting Machine

The copper in the stator can be easily removed in only two steps of cutting and pulling.

Scrap Metal Rotor Motor Stator Copper Cutting And Seperating Machine is a multi-function motor stator recovery machine, three function in one, cutting copper wire, grab copper wire from small stators, pull copper wire from big stators.

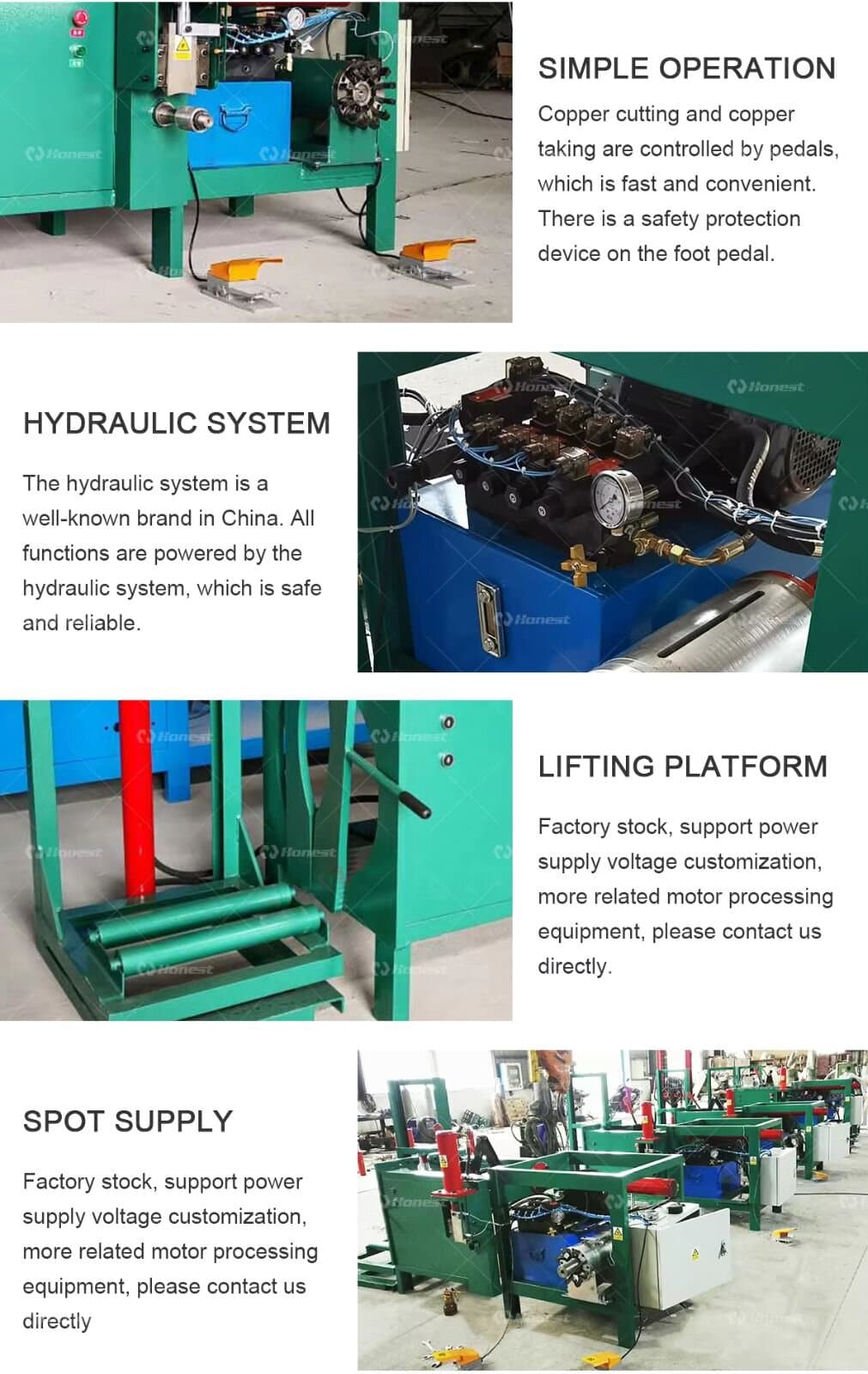

Simple Operation : Copper cutting and copper taking are controlled by pedals, which is fast and convenient. There is a safety protection device on the foot pedal.

Hydraulic System : The hydraulic system is a well-known brand in China. All functions are powered by the hydraulic system, which is safe and reliable.

Lifting Platform : Humanized design saves manpower for handling large stators. This function is controlled by buttons and powered by hydraulic system.

Spot Supply : Factory stock, support power and voltage customization, more related motor processing equipment, please contact us directly.

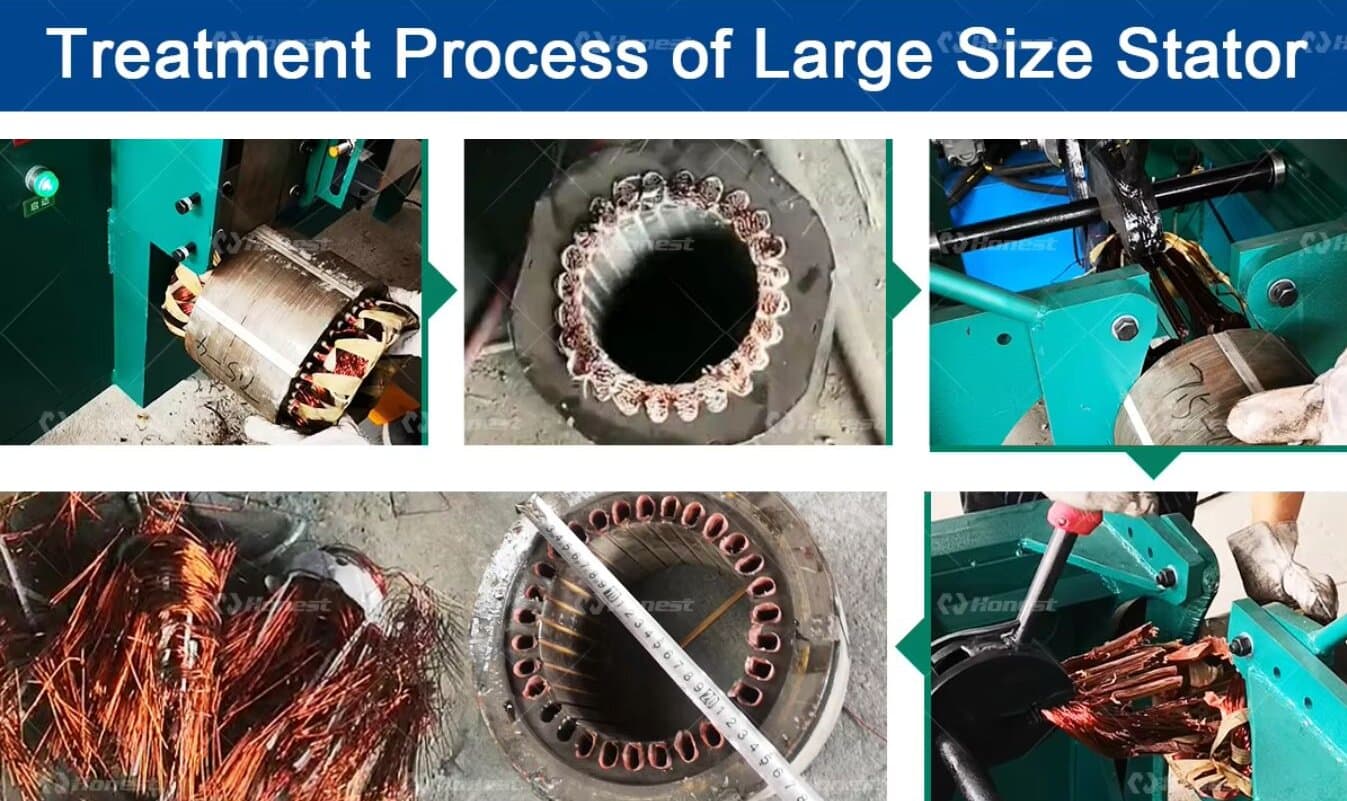

Treatment Process of Motor Stator Copper Cutting and Extracting Machine

1. Firstly , put the stator in the cutter part, firstly cut the copper roll which ledge part . Then you get the head and main body.

2. The head part will use the claw type holder to get the copper.

1. Firstly , put the stator in the cutter part, firstly cut the copper roll which ledge part . Then you get the head and main body.

2. The main body will be separated with the pinchers type holder

Equipped with a durable alloy knife and adjustable cutter distance, the machine can adapt to stators of various sizes.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export