Equipment Features

Main Applications:Fine wire and jelly-filled cable recycling

Raw Materials:Thin copper wires, jelly-filled/oil-coated cables

Main Final Products:Copper granules and plastic

If you want to start your recycling business, feel free to contact us.

The machine features an integrated structure design, occupying less space and allowing for single-person operation. An optional dryer and magnetic extractor are available to improve the recovery rate.A perfect solution for small-scale recyclers or anyone seeking high-purity copper separation with minimal environmental impact.

Mini Wet Copper Wire Granulator Machine Product Usage / Application:

This machine is widely used for processing jelly-filled communication cables, oil-coated wires, household electrical wires, automotive wire harnesses, and other mixed plastic and copper cables.

Its water-based separation technology offers a highly efficient way to extract clean copper from complex cables where traditional dry methods often fail or result in excessive material loss.

Technical Parameters

| Item | Specification |

|---|---|

| Machine Name | Shredding & Sorting Unit |

| Machine Dimensions | 3000mm × 1500mm × 2000mm |

| Moving Blades | 15 pcs |

| Fixed Blades | 2 pcs |

| Blade Material | Cr12MoV |

| Rotation Speed | 900 rpm |

| Total Power | 17.25kW (15kW + 0.75kW + 0.75kW + 0.75kW) |

| Water Tank | 1 set (304 stainless steel) |

| Control Cabinet | 1 set (CHINT brand) |

| Screen Size | Φ4mm |

| Daily Output (10h operation) | 1–2 tons (Approx.) |

| Total Weight | 1400 kg |

Product Structure Mini Wet Copper Wire Granulator Machine

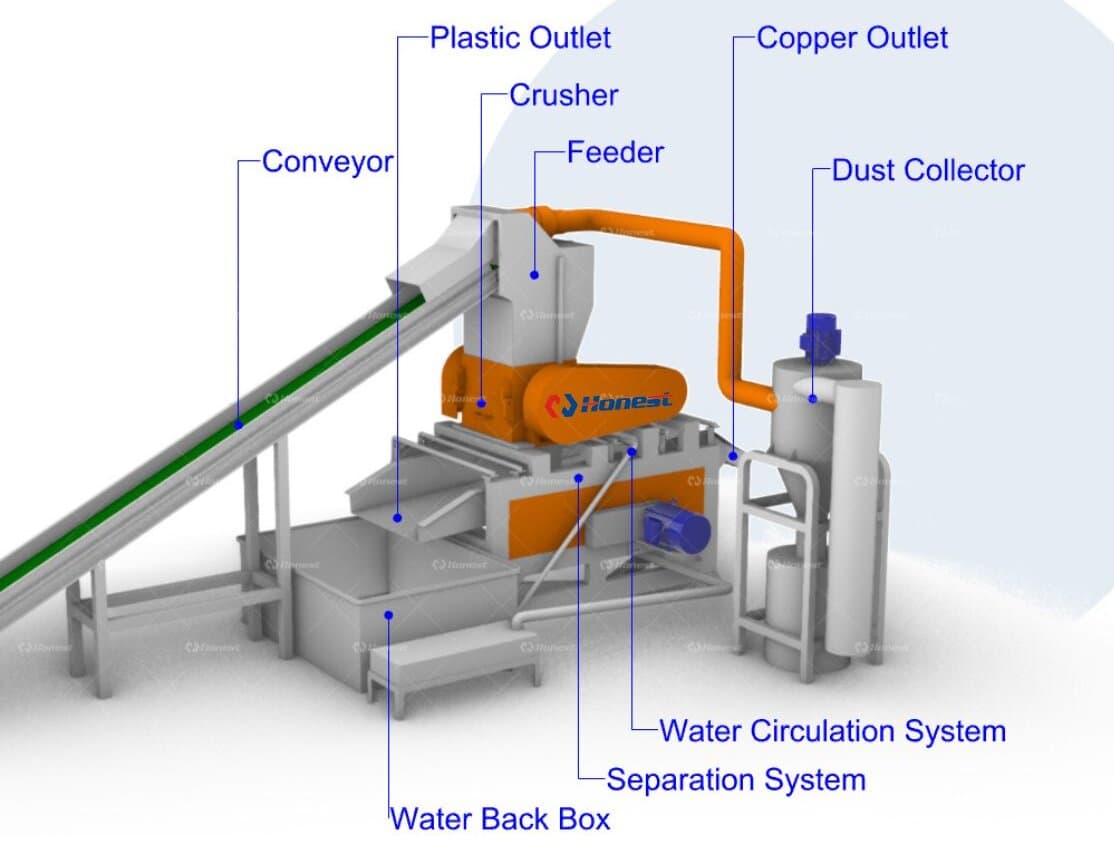

The Mini Wet Copper Wire Granulator Machine features a compact, integrated structure that combines feeding, crushing, separation, dehydration, and dust collection into one efficient system. Wires are fed into the machine through a controlled input section and processed by a high-strength crusher equipped with staggered alloy blades, which efficiently cut and reduce the size of copper wires and their insulation. The crushed mixture then enters a water-based separation tank, where copper and plastic are separated by specific gravity. The clean copper and plastic materials exit through separate outlets and are ready for reuse or resale.

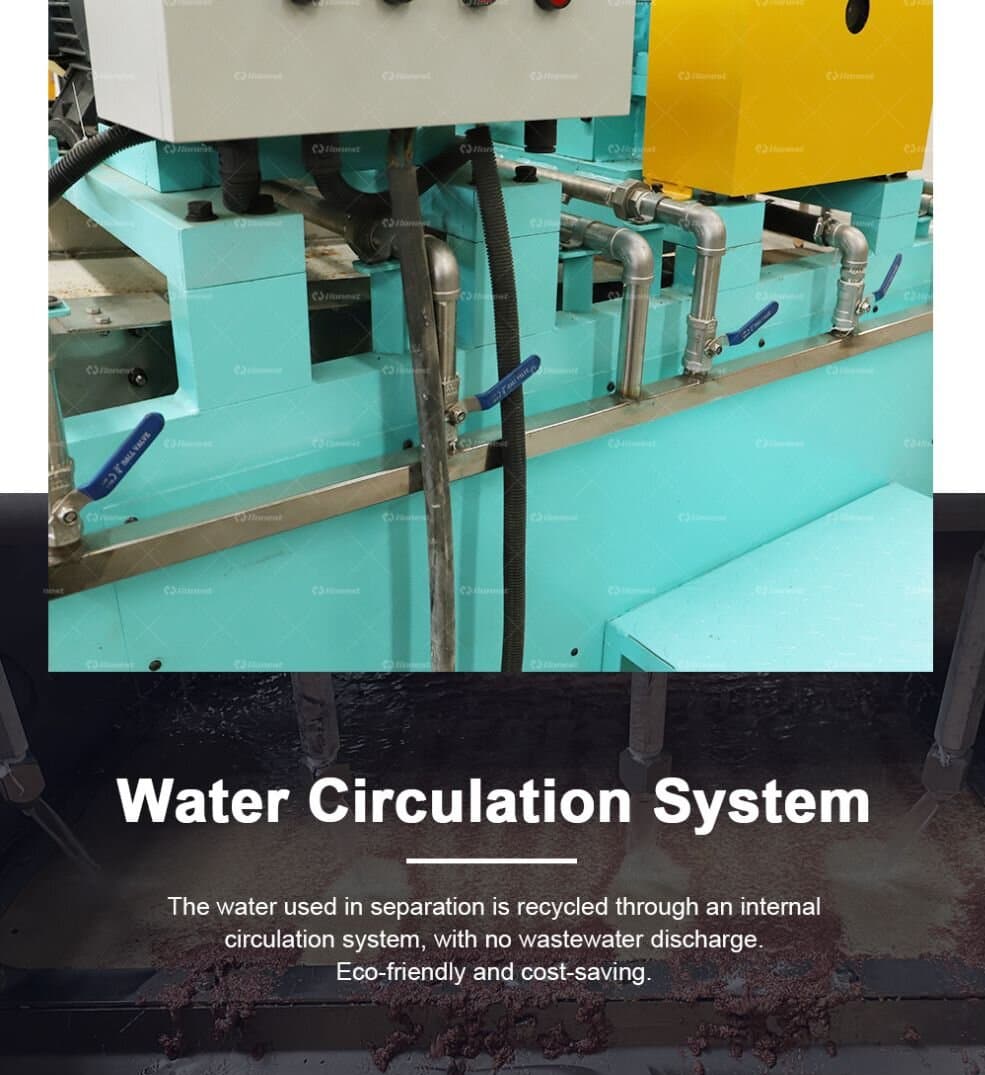

The system includes a closed-loop water circulation design, ensuring no wastewater discharge and environmentally friendly operation. An intelligent PLC control system with a touchscreen interface manages the process with automation features such as reverse rotation, overload protection, and real-time monitoring. An integrated dust collection unit completes the structure, ensuring clean, safe, and pollution-free operation in all working environments.

Key components of Mini Wet Copper Wire Granulator Machine

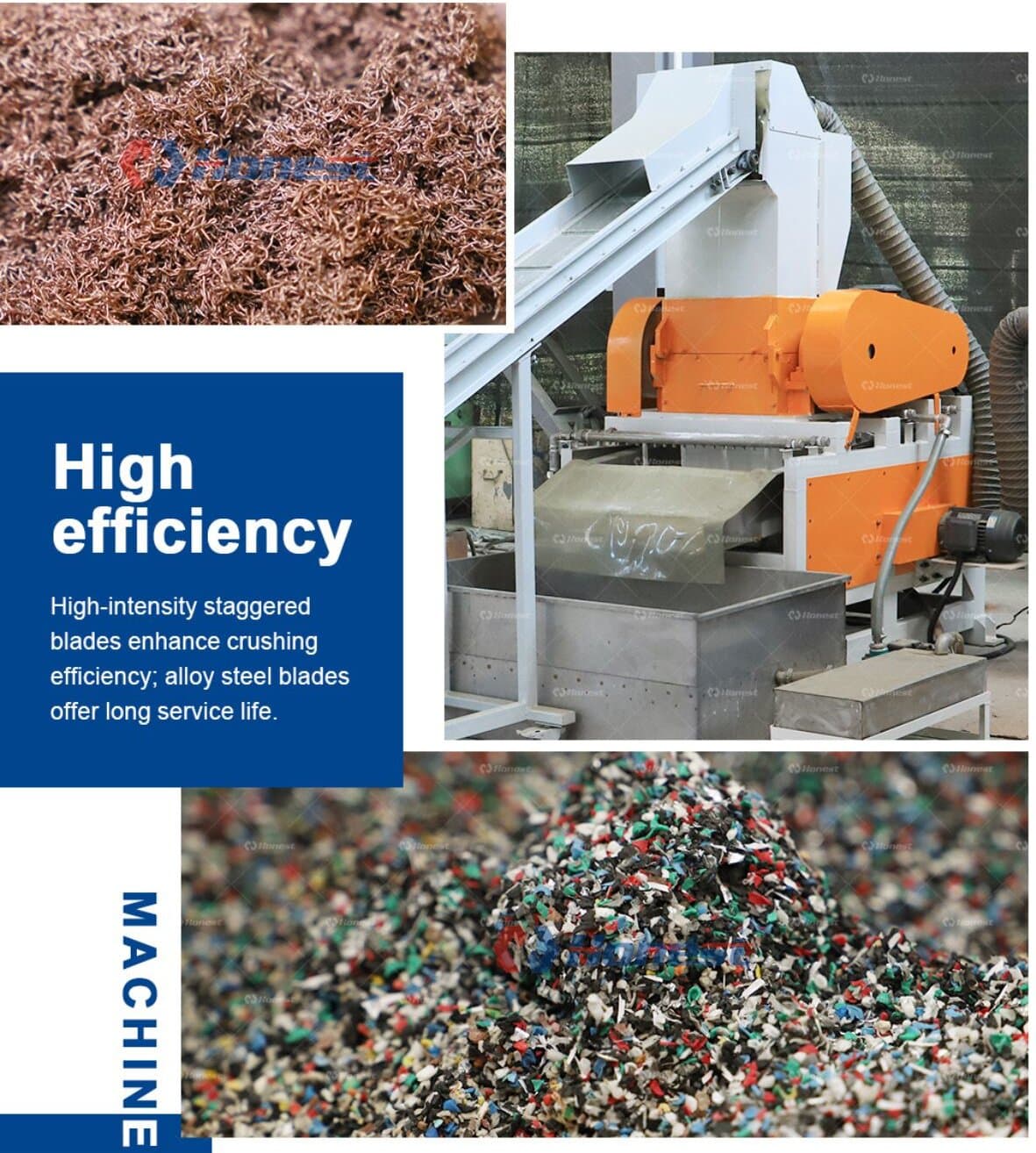

High efficiency : High-intensity staggered blades enhance crushing efficiency, and alloy steel blades offer long service life.

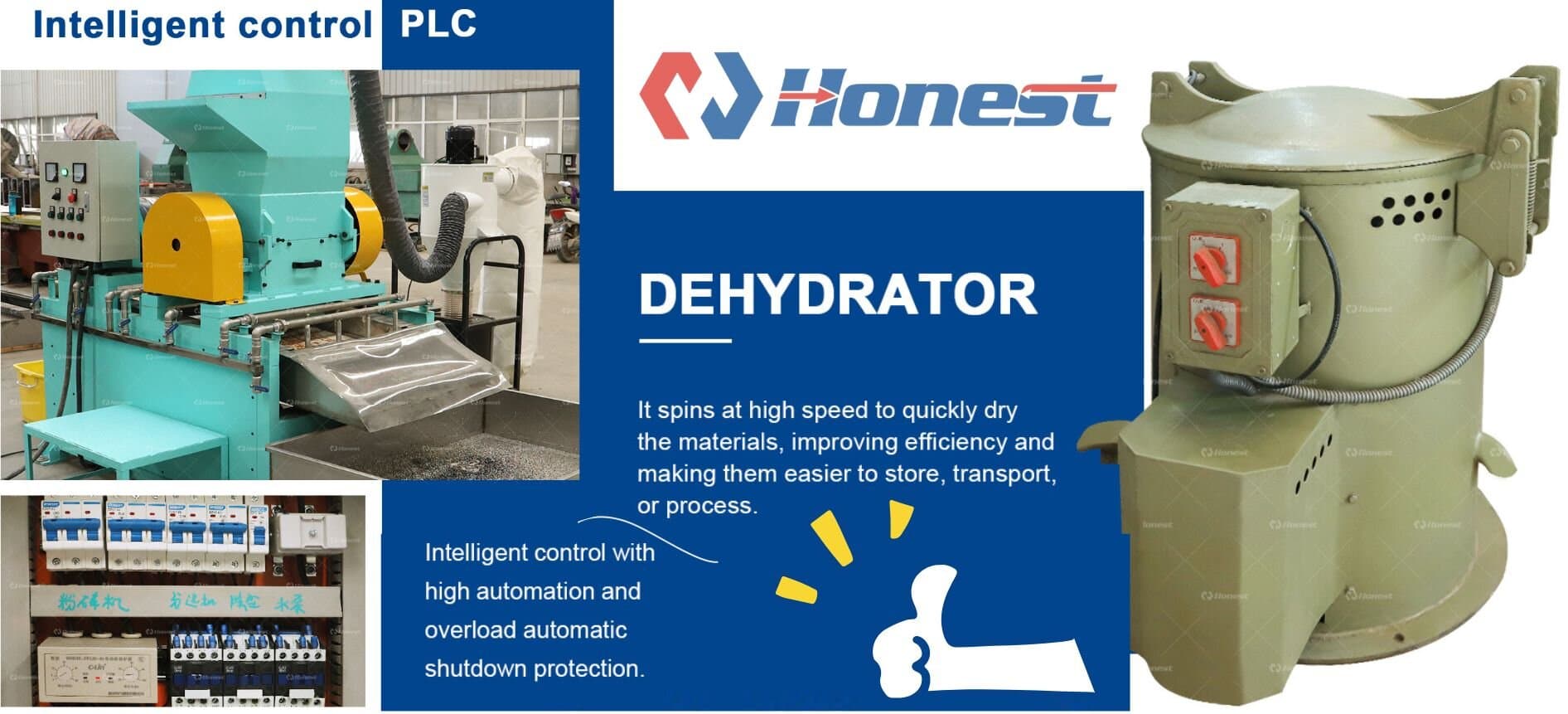

Intelligent control PLC : Intelligent control with high automation and overload automatic shutdown protection.

DEHYDRATOR : It spins at high speed to quickly dry the materials, improving efficiency and making them easier to store, transport, or process

POLLUTICNFREE : Environmentally friendly operation, equipped with an adjustable collector system.

Water Circulation System The water used in separation is recycled through an internal circulation system, with no wastewater discharge. Eco-friendly and cost-saving.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export