Equipment Features

Main Applications:Crush various wastes into small pieces

Raw Materials:For processing various brittle materials

Main Final Products:Reduced size pieces of various materials

If you want to start your recycling business, feel free to contact us.

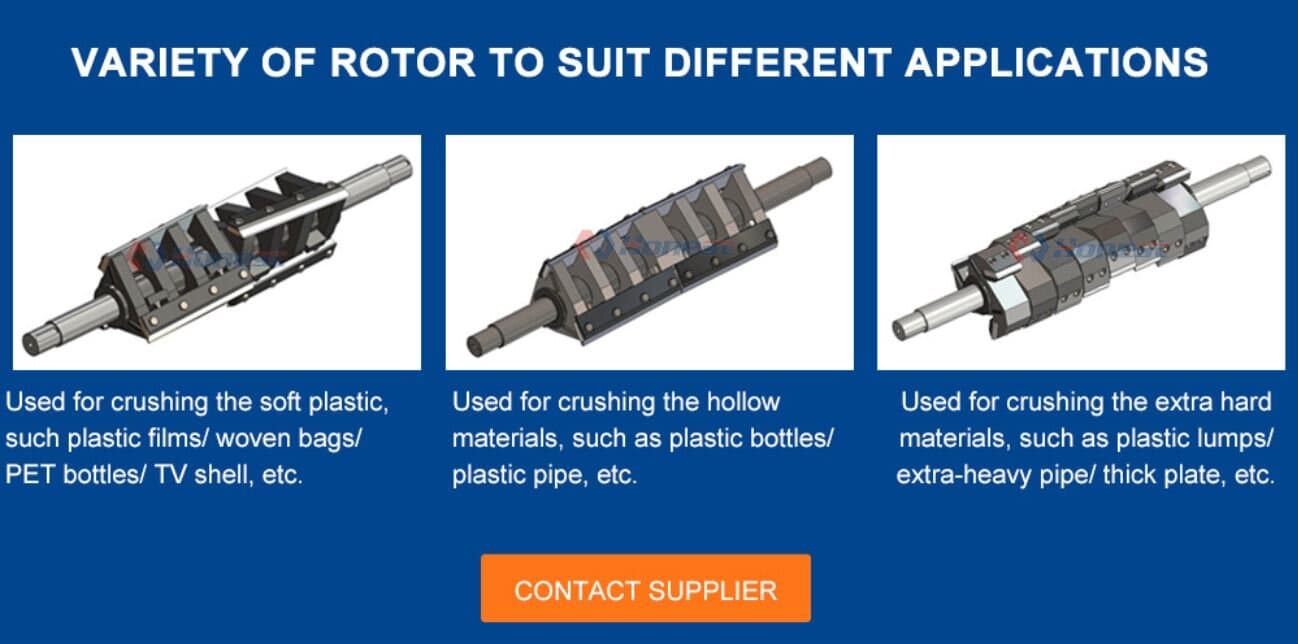

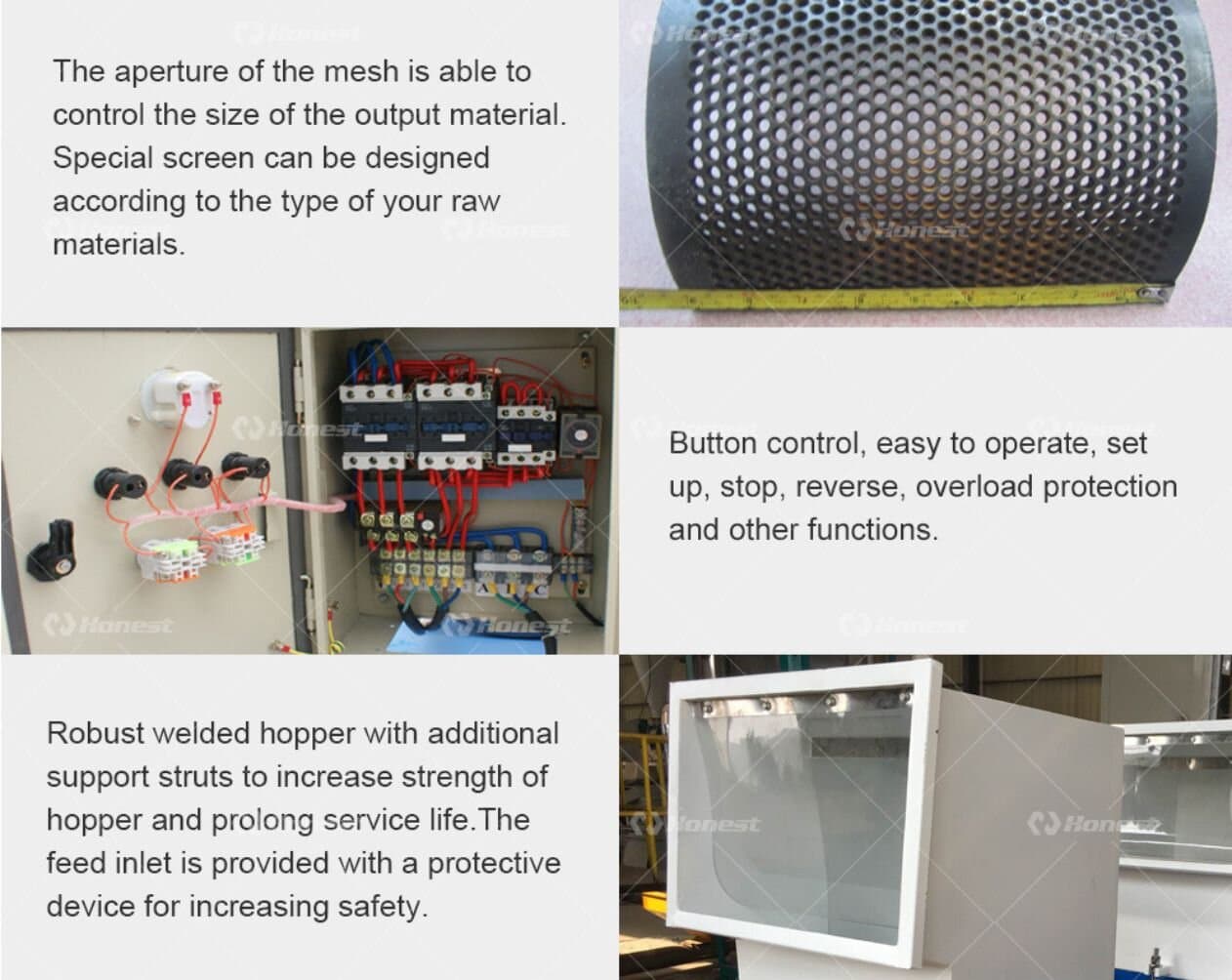

Knife crushers are industrial machines that utilize sharp rotating blades to reduce the size of various materials. Its provides an effective way to reduce the size of various materials through a precise cutting action, often using screens with various hole sizes to control the output particle size. The blades are made of hardened steel or other durable materials to withstand wear and tear.

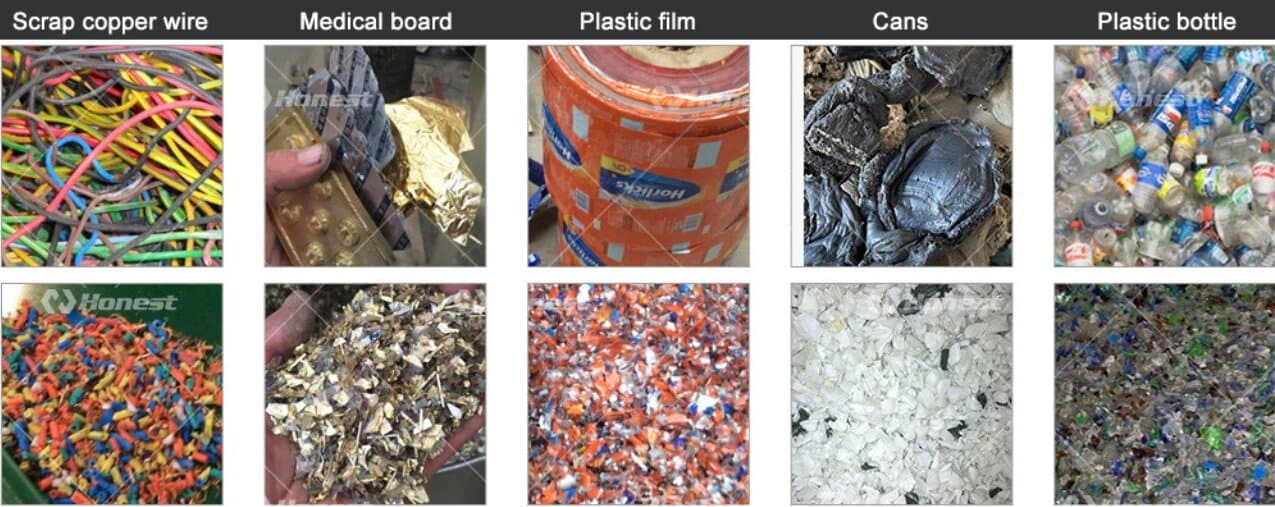

Raw Material

Knife crusher is suitable for all kinds of waste materials, including plastic beverage cans, plastic drums, iron drums, packing boxes, packing barrels and other kinds of hollow containers, TV sets, washing machines, refrigerator shells and other waste household appliances, large pipes, pipe fittings and PE pipes and other piping materials, Knife crusher is suitable for all kinds of waste materials, including plastic beverage cans, plastic drums, iron drums, packing boxes, packing barrels and other kinds of hollow containers, TV sets, washing machine, refrigerator shells and other waste household appliances, large pipes, pipe fittings and PE pipes and other piping materials, wooden pallets, plastic pallets and forklift trucks and other waste templates, automobile tires, truck tires and other waste tires, automobile shells, aluminum alloys, waste cast aluminum parts, engine shells, lead and steel plates with a thickness of less than 5mm and other waste metals, as well as kitchen wastes, household wastes, RDF derivatives, medical wastes, bio orange poles, garden waste and other kinds of garbage, industrial wastes such as rubber headstock and paper mill ropes.

Final Products

After crushing, most large plastics or other materials will be reduced in size by up to 30%, with some materials up to 50% in size after crushing.

Technical Parameters

| Model | HN-KC-600 | HN-KC-800 | HN-KC-1000 | HN-KC-1200 |

| Feed inlet size | 0.6×0.32m | 0.82×0.6m | 1.02×0.65m | 1.2×1m |

| Rotating diameter | φ0.27m | φ0.42m | φ0.42m | φ0.7m |

| Power | 15KW 20HP | 42037kw | 45KW 60IP | 55Kw |

| Rotation Speed | 380 r/min | 480 r/min | 480 r/min | 380 r/min |

| Voltage | 3380V50HZ | 3380V50HZ | 3380V50HZ | 3380V50HZ |

| Machine Size | 1.15×1.5×1.6m | 1.6×1.68×2.08m | 2×1.8×2.4m | 3×1.8×4m |

| Weight | 660kg | 2300kg | 3500kg | 6000kg |

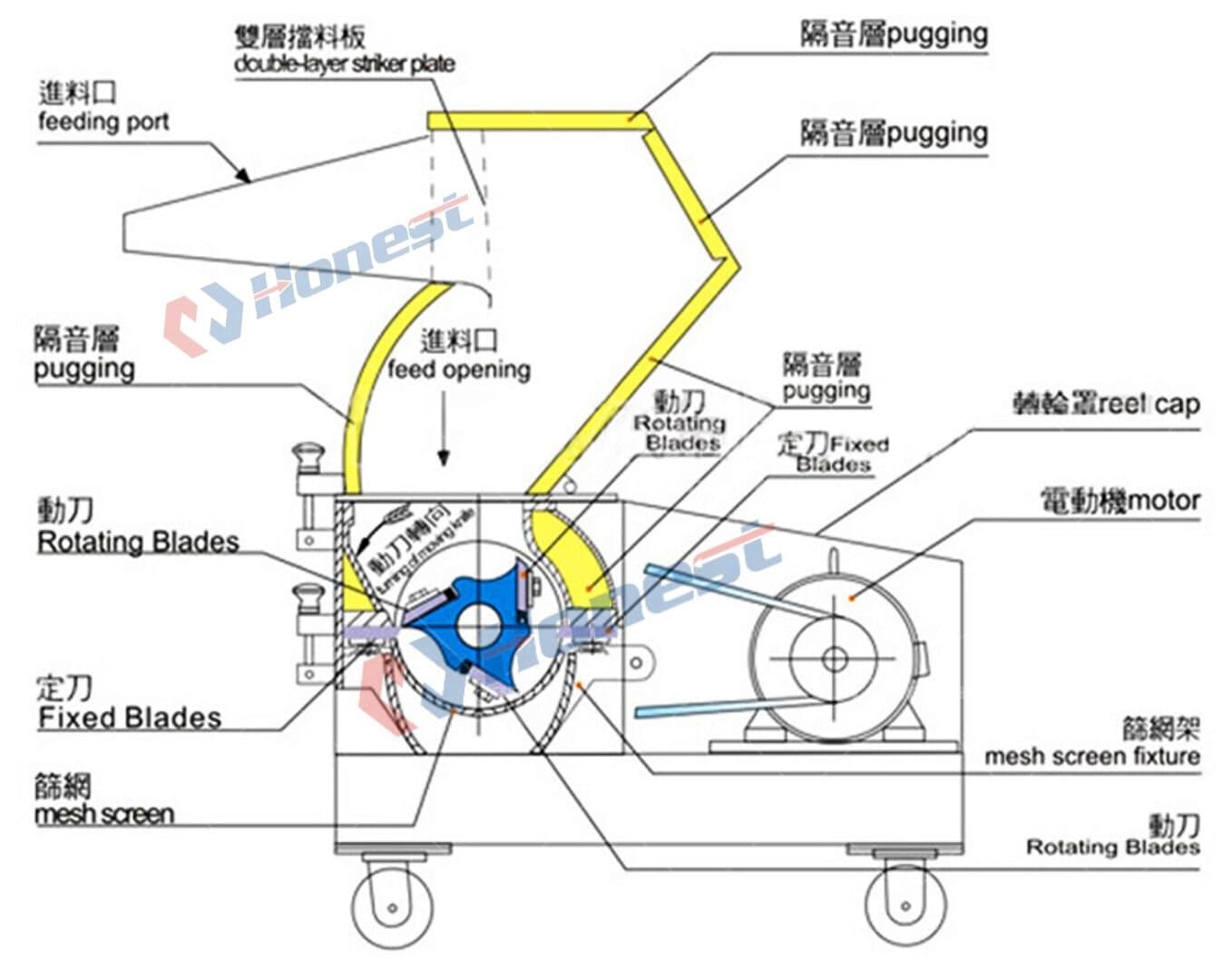

Knife Crusher Machine Brief Introduction

Feeding port/feed opening: Used to put in the materials to be crushed.

Double-layer striker plate: the material firstly hits this plate after entering, which helps to disperse the material.

Rotating Blades: Driven by motor, it is the main crushing part.

Fixed Blades: Fixed and immobile, cooperating with the movable blades, shearing and crushing the materials.

Mesh Screen Fixture and Mesh Screen: Screening the crushed materials and controlling the size of the discharged materials.

Pugging: wrapped in the equipment in many places, play a role in reducing the noise of equipment operation.

Reel cap: to protect the rotor part of the motor.

Knife Crusher Machine Working Principle

Knife crushers use rotating blades that interact with fixed blades or screens by shearing or cutting the material. This cutting action is different from the crushing action of a hammer mill or other types of crushers. The design and material of the blades is critical to the performance of the crusher. Blades are made of hardened steel or other durable materials to withstand wear and tear. Different blade configurations are used to process a variety of materials.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export