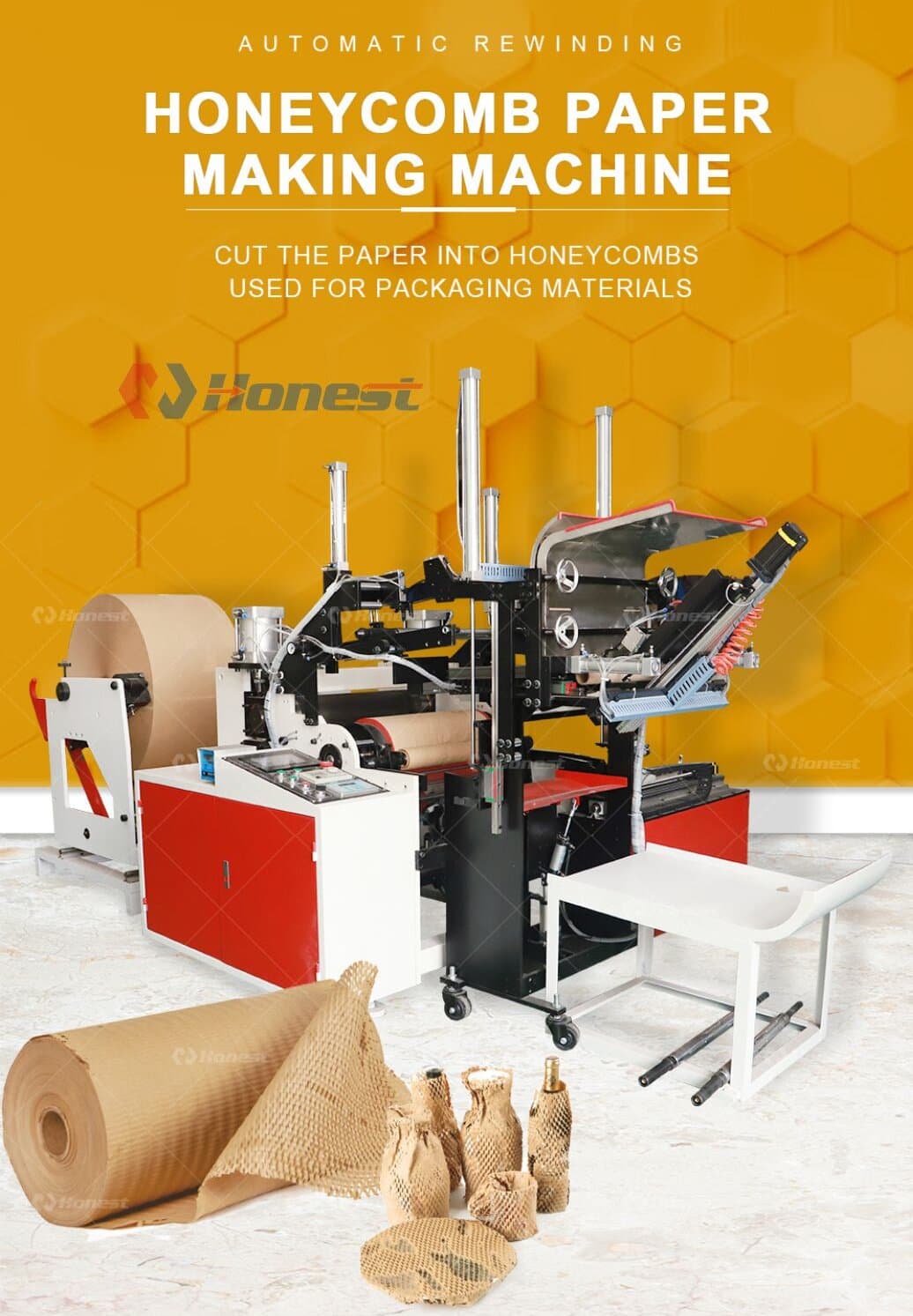

Equipment Features

Main Applications:Used to produce honeycomb paper for packaging

Raw Materials:Paper of specific sizes and in various colors

Main Final Products:Honeycomb paper for packaging

If you want to start your recycling business, feel free to contact us.

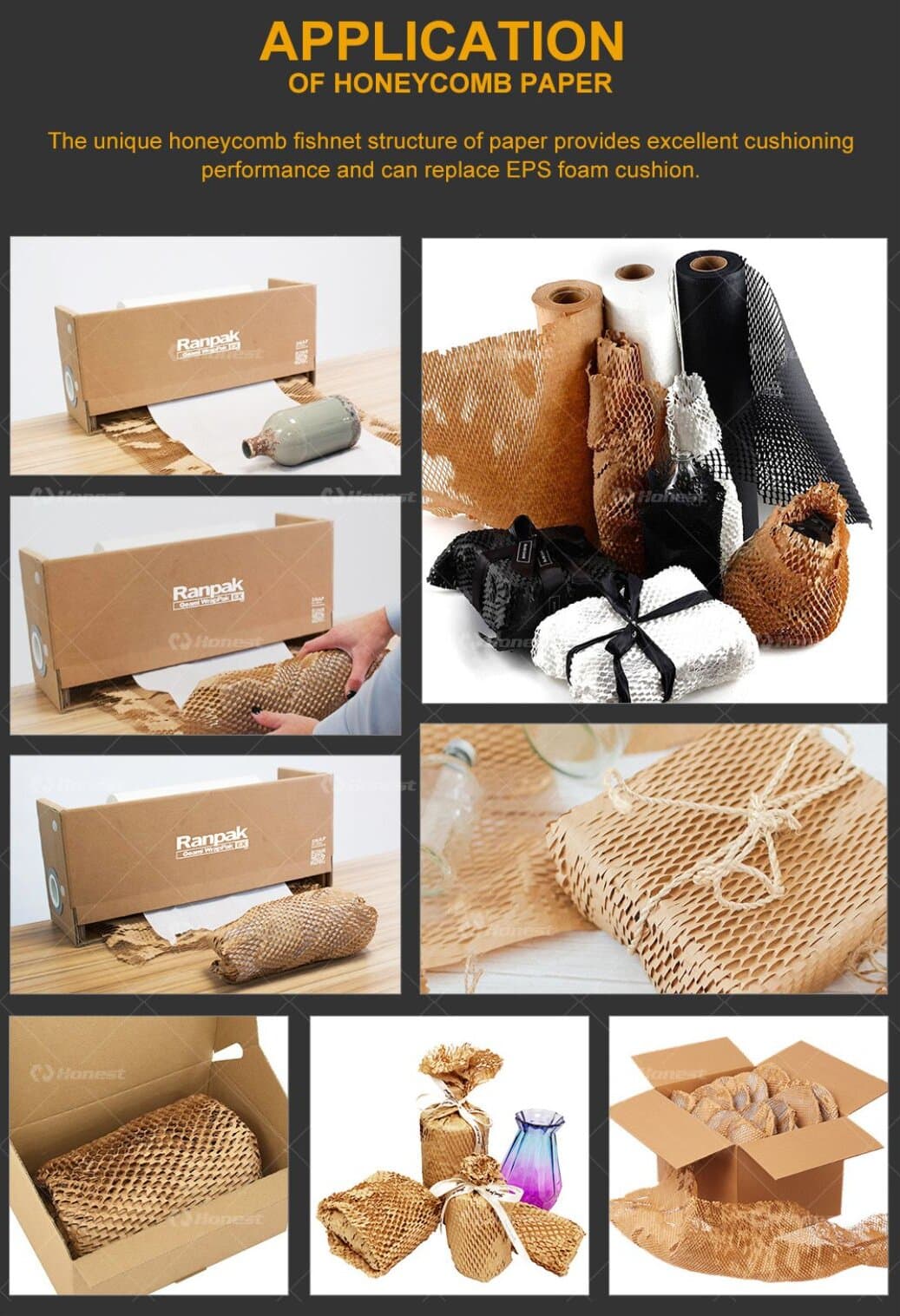

Finished Products and Application Scenarios Display

This machine is used for rewinding white paper, yellow paper, kraft paper in roll into honeycomb net. Net making and rewinding could be completed at the same time. The Gifting Packing Industry needs a lot of honeycomb Paper.

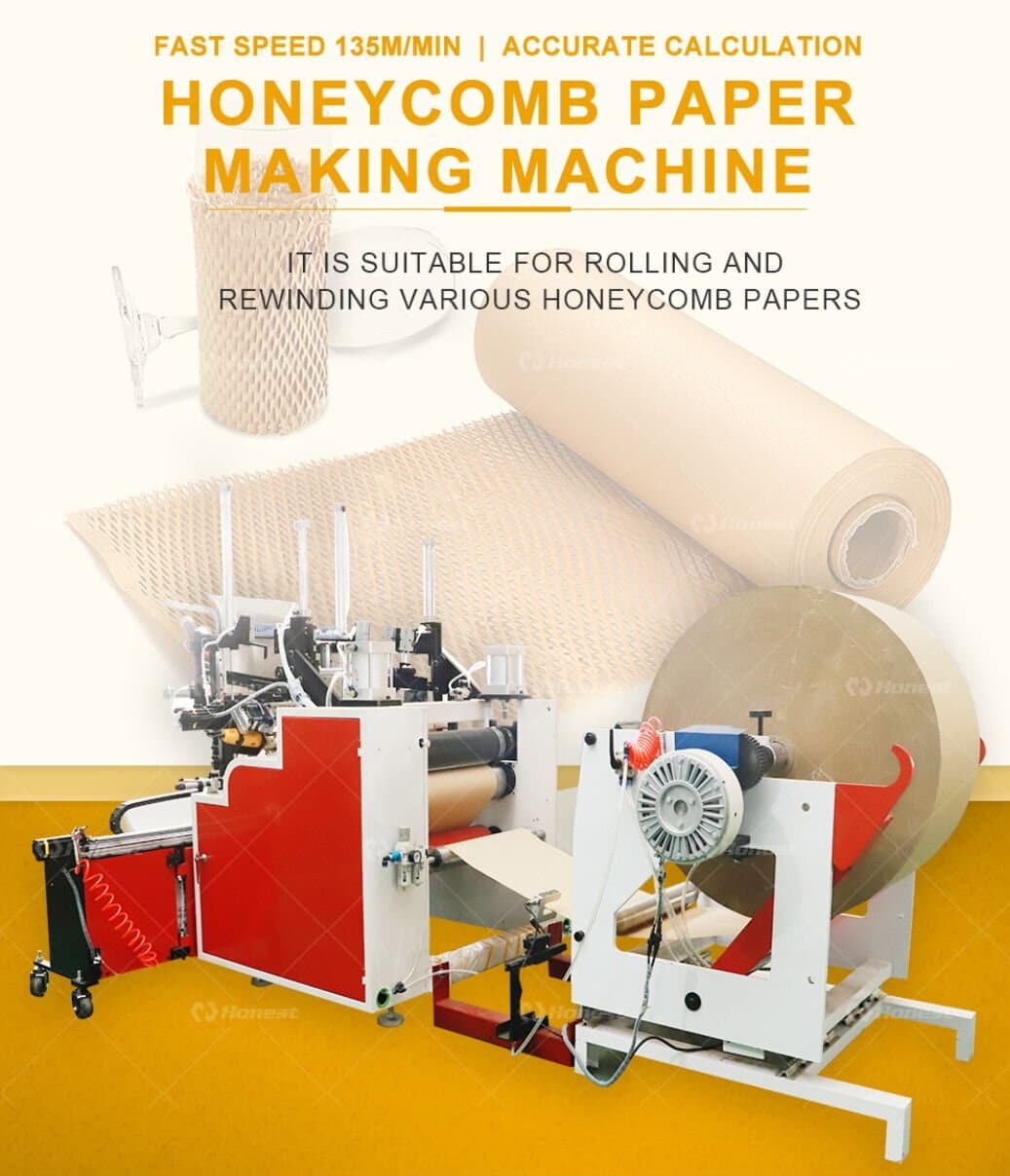

Fully Automatic Technical Parameters

| Fully Automatic Honeycomb Paper Making Machine | |

| Machine model | HN-HP-1000 |

| Maximum width of wrapping | ≤500mm |

| Maximum diameter of paper roll | ≤1200mm |

| Maximum winding speed | 135m/min |

| Voltage | 220V-380V/50Hz |

| Power | 8kw |

| Weight | 3000kg |

Semi Automatic Technical Parameters

| Semi Automatic Honeycomb Paper Making Machine | |

| Machine model | HN-HP-500 |

| Max material width | 500mm |

| Machine working speed | 0-150m/min |

| Unwinding diameter | Max. 1200mm |

| Rewinding diameter | Max. 300mm |

| Unwinding roll weight | Max. 1T |

| Unwinding shaft | 3″ |

| Rewinding shaft | 3″ |

| Machine size | 1850*1350*1300mm (L*W*H) |

| Machine weight | 1800KG |

| Machine power | 5KW |

| Power supply | 380V, 3 Phase, 50Hz |

Key components of Honeycomb Pack Paper Making Machine

The system utilizes frequency conversion speed regulation and full integrated circuit control to ensure precise operation, maintaining consistent tension and repeatability throughout production. Its durable cutter shaft withstands over 200,000 cycles with automatic rollover counting for extended service life.

Automation is at the core of this machine’s design, incorporating magnetic powder tension control and ultrasonic auto-correction to guarantee smooth material handling. The PLC-controlled system allows for customizable roll lengths with automatic calculation and seamless roll replacement.

For reliable, efficient production of sustainable packaging materials, this honeycomb paper making machine offers an ideal solution. Contact us to learn more about its capabilities.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export