Equipment Features

Main Applications:Mainly used for separating non-ferrous metaland non metal

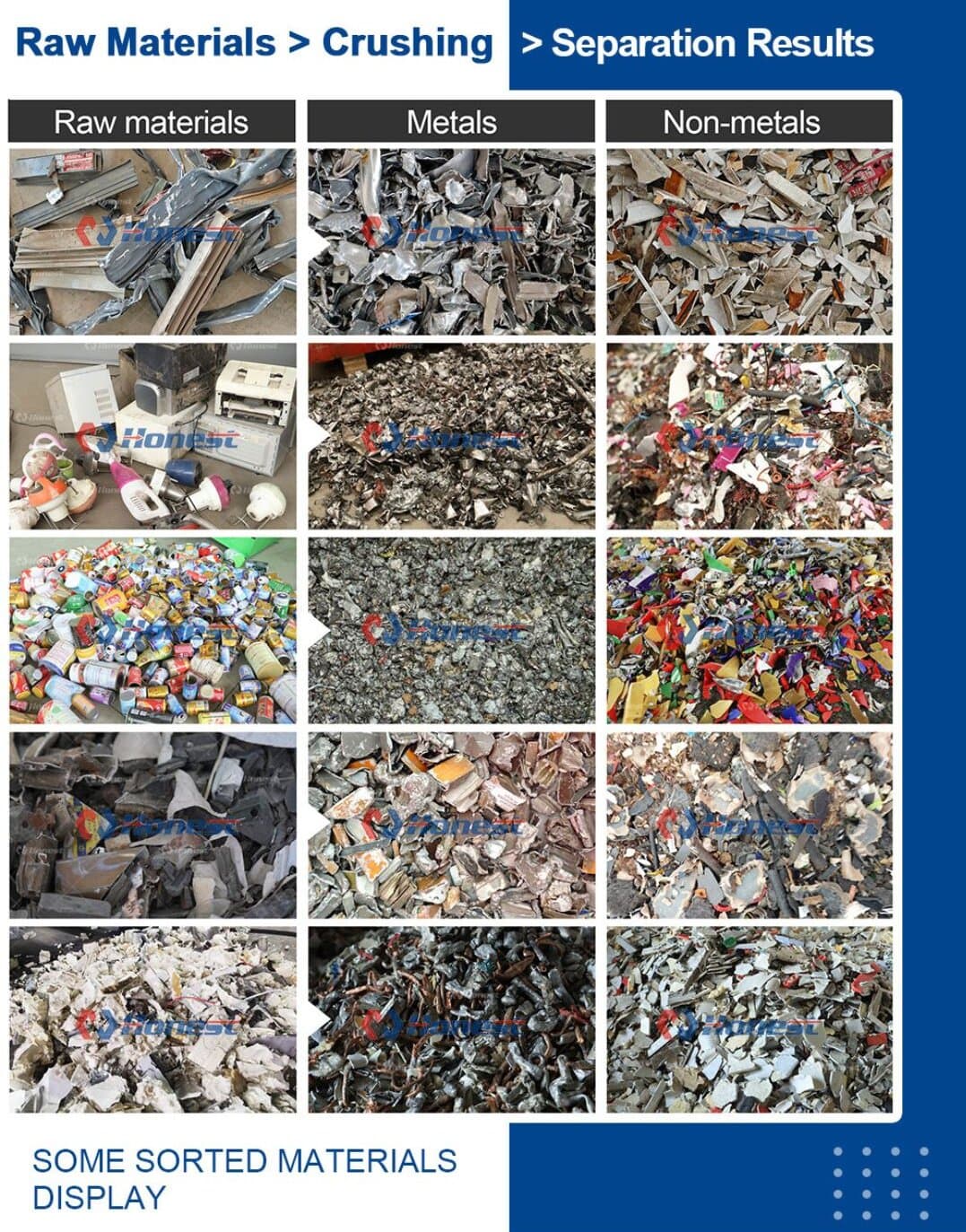

Raw Materials:Mixed waste streams (industrial waste, municipal solid waste and electronic waste)

Main Final Products:non-ferrous metals and non-metallic materials

If you want to start your recycling business, feel free to contact us.

The Eddy Current Separator is designed for efficient separation of non-ferrous metals such as copper, aluminum, and other conductive metals from industrial waste, municipal solid waste, and various recycling materials. It plays a key role in the environmental protection and resource recovery industry.

Eddy Current Separator Machine Product Usage / Application:

Aluminum-plastic composite materials, copper-plastic composite materials, metals and non-metals, and plastics and metals.

Circuit boards are separated from waste household appliances after dismantling, PCB circuitboard leftover materials.

Circuit board drilling powder waste, miscellaneous wires, waste home appliance dismantling wires, copper-plastic wires, fine flexible cables, computer connection wires, automobile and motorcycle battery cables, and automotive wiring harnesses.

Aluminum-plastic wires, sheathed wires, automotive copper-aluminum radiators, air conditioner radiators for separating aluminum and copper, garbage material sorting from metals, plastics, and non-ferrous metals.

PET bottle flakes containing aluminum for separation, non-ferrous metals recovered from crushed waste appliances such as automobiles and refrigerators, aluminum separation from automobile sealing strips, and aluminum foil separation from PC plastics.

Aluminum-plastic doors and windows are used to separate aluminum from other mixed metal and non-metal materials.

Technical Parameters

| Model | Belt Width | Capacity | Driving Power | Weight | Overall Dimensions |

| HN-EC-600 | 750 mm | 0.5~0.8 t/h | 0.25×2 + 2.2 + 1.5 + 4 kW | 3520 kg | 5.3×2.35×2.2 m |

| HN-EC-800 | 950 mm | 1~1.5 t/h | 0.37×2 + 2.2 + 1.5 + 4 kW | 3760 kg | 5.3×2.55×2.2 m |

| HN-EC-1000 | 1150 mm | 1.5~2 t/h | 0.37×2 + 2.2 + 1.5 + 4 kW | 4100 kg | 5.3×2.75×2.2 m |

| HN-EC-1200 | 1350 mm | 2~3 t/h | 0.37×2 + 2.2 + 1.5 + 5.5 kW | 4290 kg | 5.3×2.95×2.2 m |

| HN-EC-1500 | 1650 mm | 3~5 t/h | 0.75×2 + 3 + 1.5 + 7.5 kW | 4610 kg | 5.3×3.2×2.2 m |

| Common Parameters: Magnetic Roller Diameter: 270 mm | Magnetic Roller Speed: 0~3000 r/min | |||||

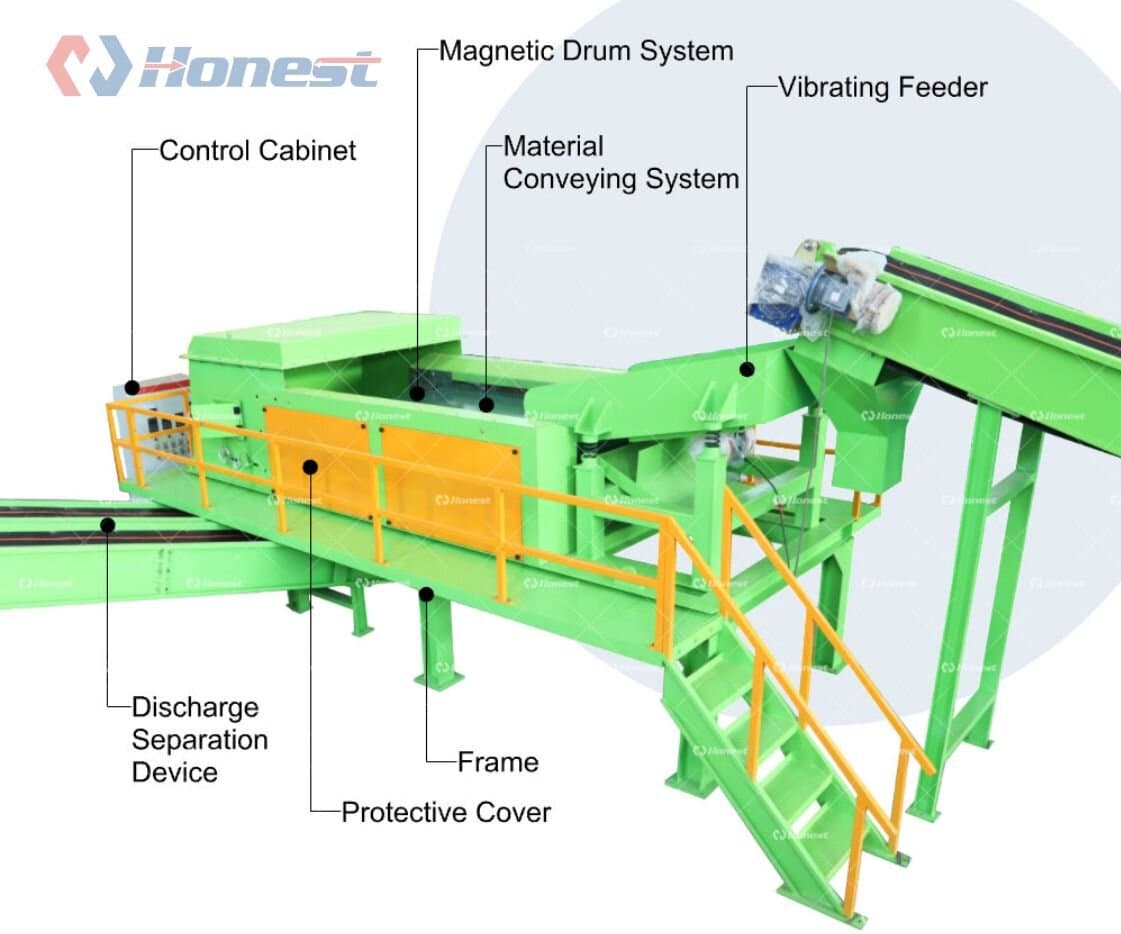

Product Structure Eddy Current Separator Machine

The main body primarily consists of an assembly, a drive motor, a frame, a cover, and other components. The sorting section is the core part of the equipment and is composed of a rotating drum and a material conveying system, which includes the material conveyor belt, the belt drive drum, and the speed reduction motor.

Process Description of Eddy Current Separator Machine

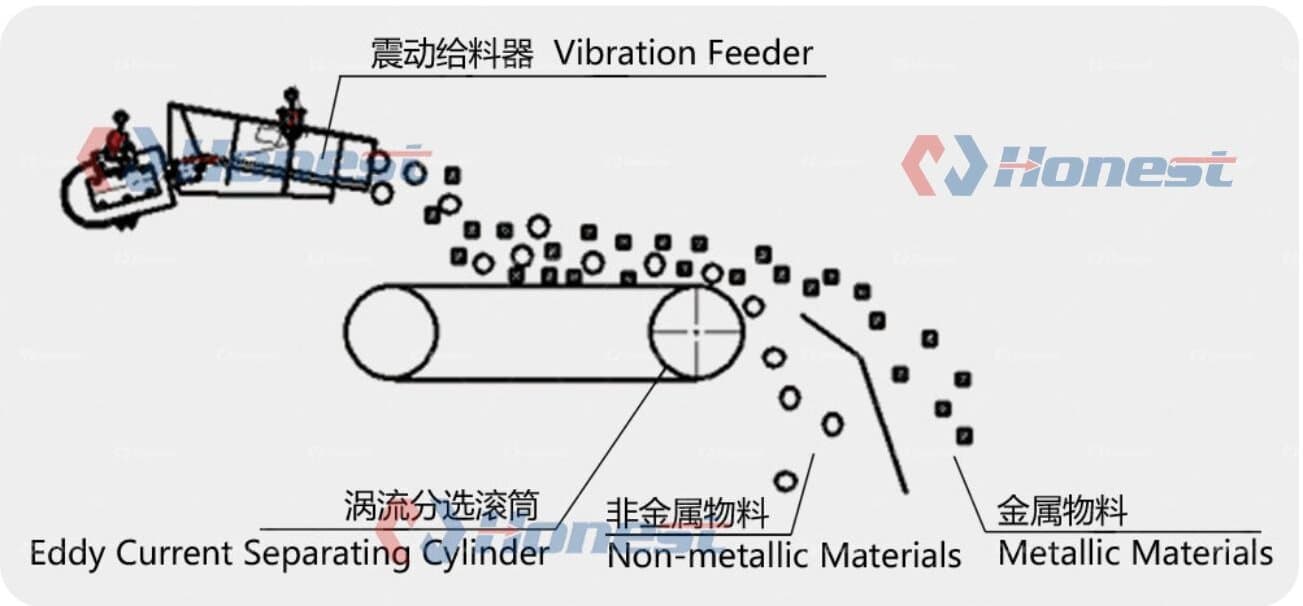

It’s based on the principle that a conductor in a high frequency alternating magnetic field can generate induced current, it’ll produce high frequency alternating intense magnetic field in the surface of magnetic roller while working, When the non-ferrous metal with electrical conductivity throughthe magnetic field, and will induced eddy current in the non-ferrous metal. The eddy current itself will generate the magnetic field opposite to the original direction. The Non-ferrous metal (such as aluminumcopper, etc.) will leap with the conveying direction, due to the repulsion of the magnetic field, to achieve the purpose of separation, separating the metal and non-metal materials. The main criterion to distinguish is the ratio of material conductivity and density values; the higher ratio value is more likely to separate.

Key components of Eddy Current Separator Machine

WIDE PARTICLE RANGE : Capable of separating a wide range of metal particle sizes, typically from 3 mm to 100 mm.

FLEXIBLE INSTALLATION : Customizable to customer requirements, and seamlessly integrated with new or existing production lines

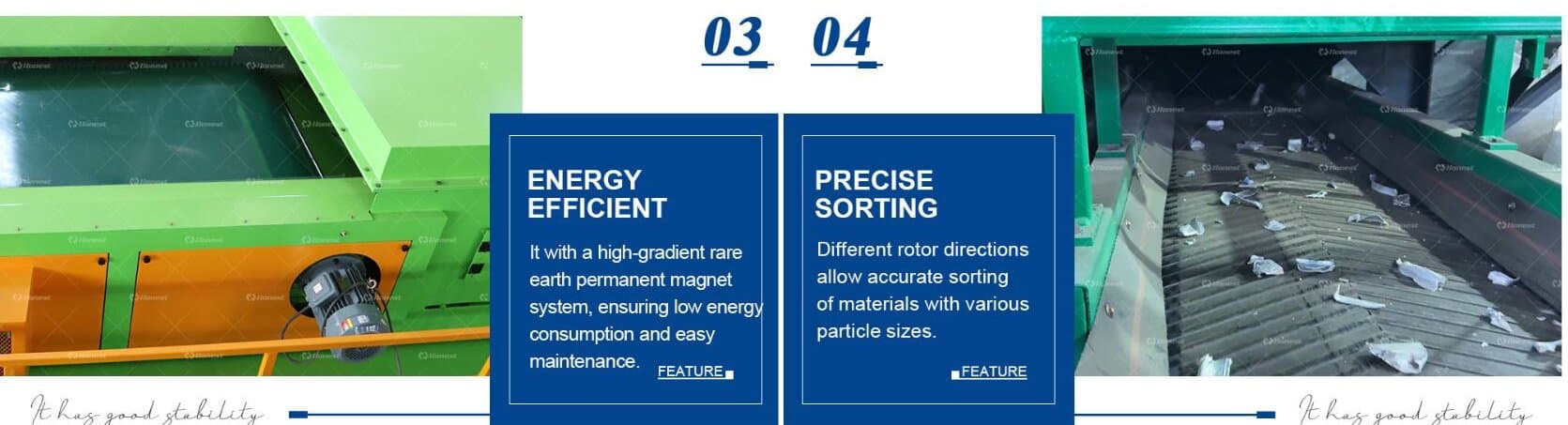

ENERGY EFFICIENT : It is with a high-gradient rare-earth permanent magnet system, ensuring low energy consumption and easy maintenance.

PRECISE SORTING : Different rotor directions allow accurate sorting of materials with various particle sizes.

MULTIPLE MODELS : Available in various models with tray widths ranging from 300 to 1500mm to meet diverse production requirements

Before eddy current separation, the materials need to be uniform in size, which is usually achieved by pre-crushing. Our company can provide complete crushing and separation solutions tailored to the specific materials and customer requirements.

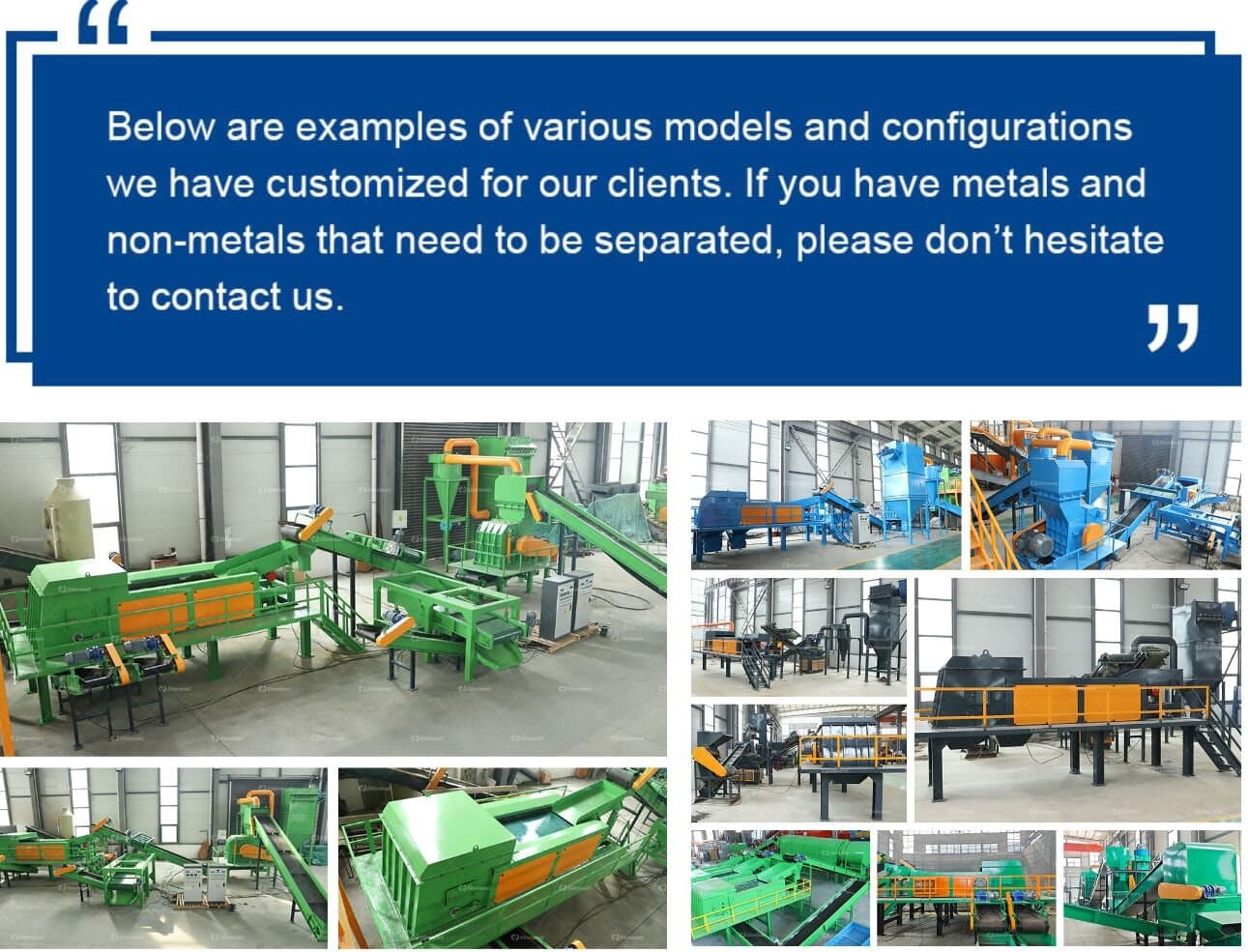

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export