Equipment Features

Main Applications:Used to recycling Waste cable wires

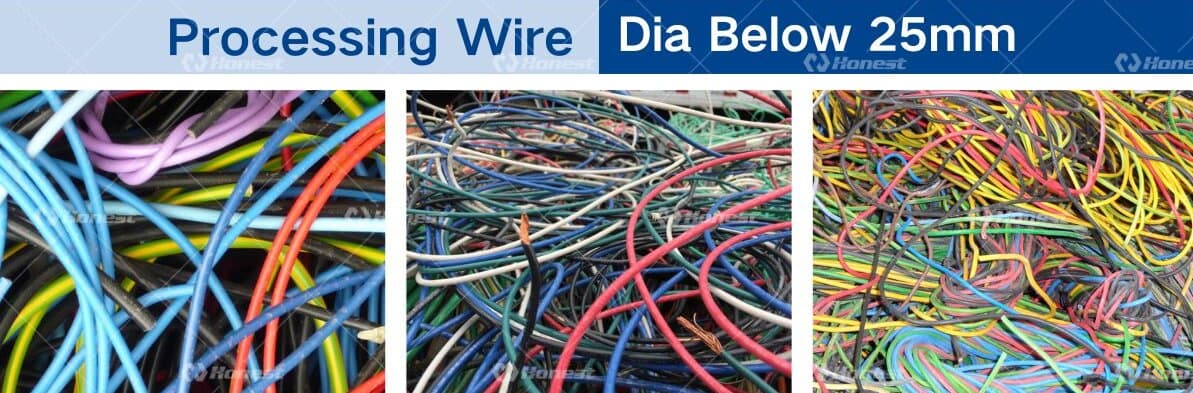

Raw Materials:Below 25mm Waste Copper Wires or Aluminum Wire and More Other Scrap Cable.

Main Final Products:Copper,Aluminum,Plastic

If you want to start your recycling business, feel free to contact us.

This Mini copper wire granulator is mainly used to recycle waste cables. It adopts a minimalist design, small capacity (30-50 kg/h), small space and low cost. It is very suitable for beginners in the recycling business, families and small factories.

Raw Material

Widely used, it can process a variety of waste cables with a wire diameter less than 25mm, with a recycling rate of up to 99%.

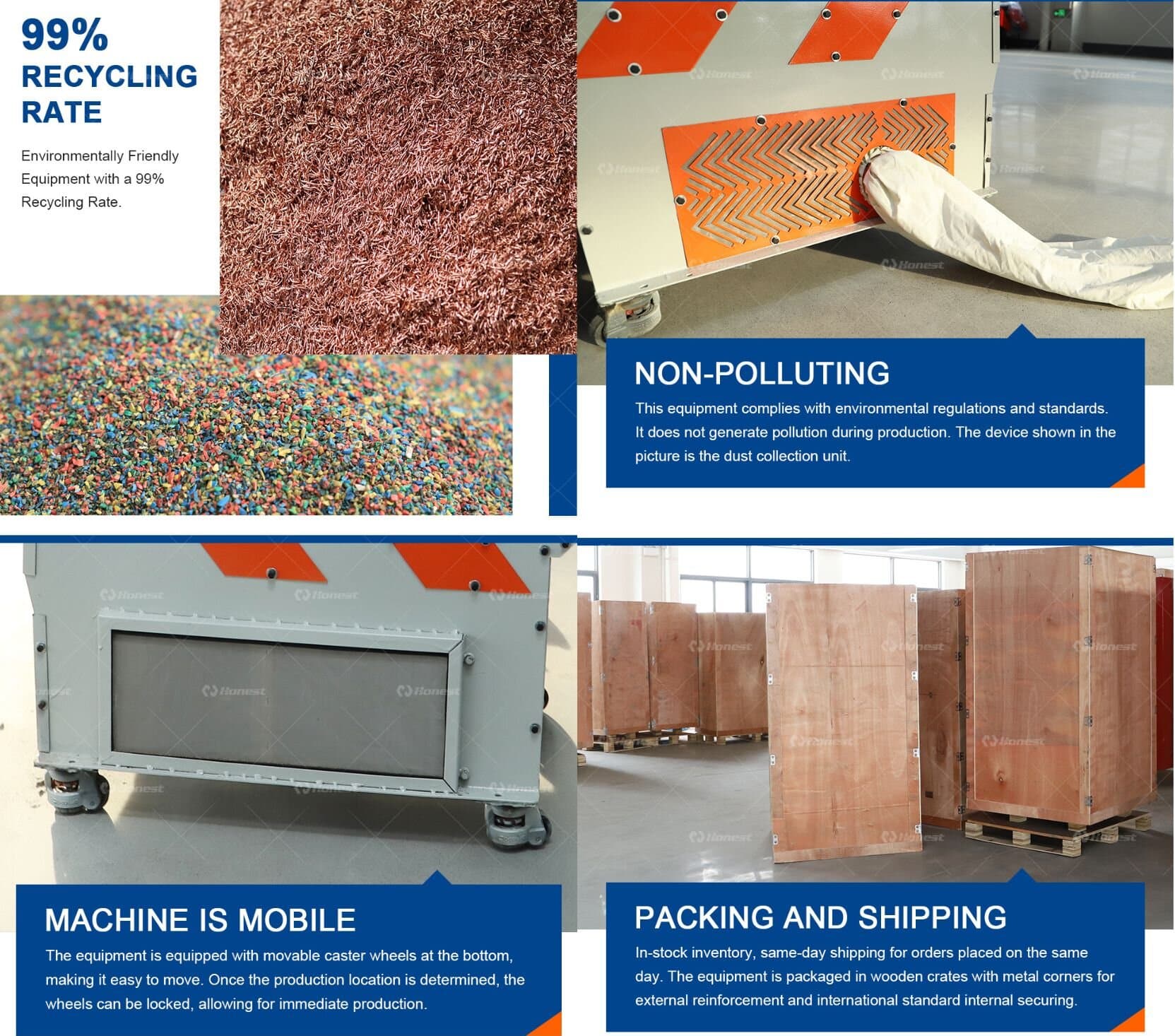

Final Products

Its main function is to separate metal (copper or aluminum) from PVC plastic shell to obtain high-purity metal (copper or aluminum) and plastic.

Technical Parameters

| Model | HN-TMJ-50 |

| Processing Capacity | 30-50kg/h |

| Power | 3.9KW |

| Voltage | 110/220V Single Phase/Three Phase (Can be Customized) |

| Processing Wire Dia | Below 25mm |

| Machine Dimensions | L830*W550*H1520(mm) |

| Weight | 265kg |

| Wooden Packing Size | L900*W620*H1740(mm) |

There is sufficient inventory and orders are shipped on the same day.

Key components of Mini copper wire granulator Machine

The Vibrating Screen is Optional.The equipment supports household power supply (single-phase electricity) and is equipped with an aviation plug for convenient home use,recovery rate is as high as 99%.

The operation is simple, with button control and a transparent observation window for easy viewing of the discharging status. The internal structure is compact, and the fully enclosed shell reduces noise and improves safety. The equipment is designed to be safe, fully enclosed, with operation buttons, and observation windows and discharging ports are provided at the front and rear.

The equipment complies with environmental regulations and standards, does not generate pollution during the production process, and is equipped with a dust collection device. The machine recovery rate is as high as 99%, which is environmentally friendly and efficient. The bottom of the equipment is equipped with lockable casters for easy movement. After determining the production location, the casters can be locked immediately for production.

There is sufficient inventory, and orders are shipped on the same day. It is packed in wooden boxes, reinforced with metal corners on the outside, and fixed inside according to international standards to ensure transportation safety.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2 Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export