Equipment Features

Main Applications:Separates copper tubes from aluminum fins in scrap AC and automotive radiators

Raw Materials:Various types of scrap AC and automotive radiators, including single, double, and triple-layer copper tube structures.

Main Final Products:Copper Tubes and Aluminum Fins

If you want to start your recycling business, feel free to contact us.

This AC Radiator Peeling Machine is a high-efficiency, eco-friendly, and automated recycling solution designed to thoroughly separate copper tubes from aluminum fins in scrap AC and automotive radiators. It ensures maximum recovery and purity of both copper and aluminum.

AC Radiator Stripping Machine Product Usage /Application:

This machine is designed to separate copper tubes and aluminum fins from waste air conditioner radiators. It is widely applicable for recycling waste AC units, old radiators, and scrapped water tanks containing mixed copper and aluminum materials.

The separation process causes no damage to the copper tubes, and the aluminum is output in block form without dust pollution.

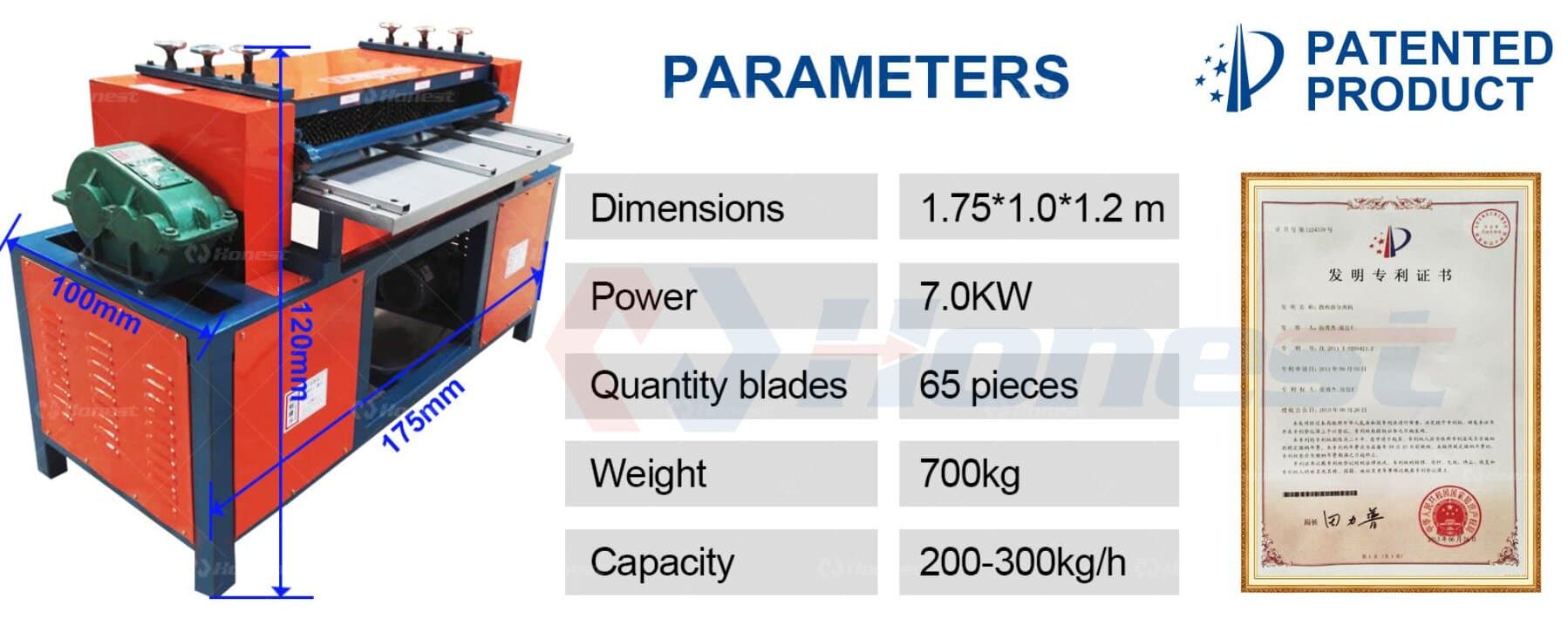

Technical Parameters

| Model | Capacity | Weight | Power | Quantity blades | Dimensions |

| HN-ACS-300 | 200-300 kg/h | 700 kg | 7 kw | 65 pieces | 1.75*1.0*1.2 m |

Key components of AC Radiator Stripping Machine

This machine is consisted of a frame, two motors, two speed reducers, material feeding part.material cutting part, material separation part, transmission part and material feeding panel. Featuring a compact structure, small footprint, easy operation, and convenient maintenance, the machine can process single- or double-layer radiators in various sizes (19mm, 21mm, 25mm).

Scrap radiators are fed into the stripping machine through the inlet. The equipment utilizes precise blades and a transmission system to accurately cut and strip the aluminum fins along the direction of the copper tubes without damaging them. Through mechanical action, the aluminum fins and copper tubes are physically separated. The separated copper tubes and aluminum fins are then discharged from different outlets into designated containers, completing the entire recycling process.

AC Radiator Stripping Machine Advantages Description:

Physical separation process, no water, no chemicals, no smoke, making it green and environmentally friendly.

Capable of processing various sizes and types of radiators, meeting diverse customer needs.

Simple structural design and intuitive control panel make it easy for workers to quickly get started after basic training.

Customers Site Overview

1. Provide field installation service to make sure the normal operation of theequipment.

2. Provide detailed technical training for customers. Including the equipmentoperation process, primary and common troubleshooting methods, etc.

3. Provide lifelong technical support for the machine.

More Solution/Product

Have this equipment demand ?

We can help you !

We will reply you in 24 hours

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now.

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export