Production Process Full-Auto Tire Recycling Machine

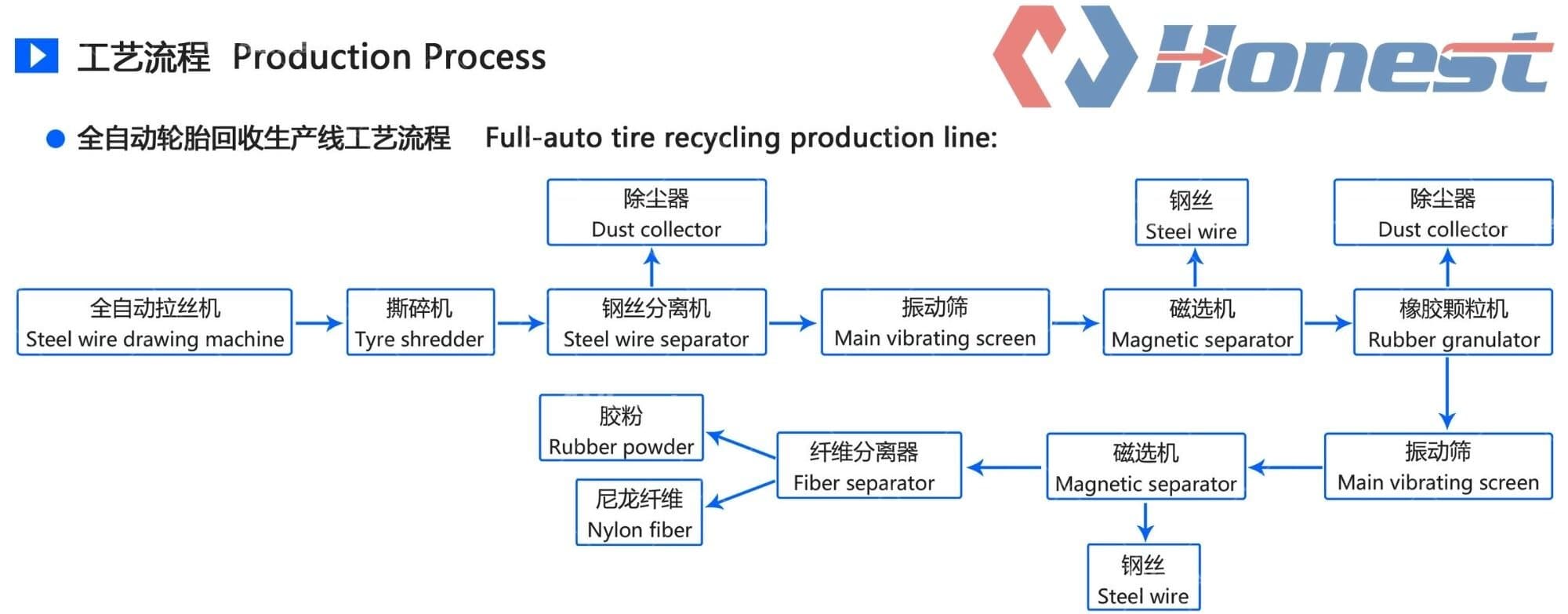

The full-automatic tire recycling line efficiently converts waste tires into valuable recycled materials. Waste tires go first to an automatic steel wire drawing machine that removes bead steel wire, reducing wear on later equipment and improving overall efficiency.

After bead wire removal, the tires enter the heavy-duty shredder, which breaks whole tires into uniform rubber blocks of about 3–8 cm. These rubber blocks are then transferred to the steel wire separator, where rubber and steel are separated through mechanical crushing and magnetic force, producing rubber granules of approximately 10–15 mm in diameter. A magnetic separator further removes the majority of steel wire, while an integrated dust collection system ensures clean operation.

Full-Auto Tire Recycling Machine

Full-Auto Tire Recycling Machine

The cleaned rubber granules are conveyed to the rubber granulator for fine grinding, reducing the material to 0–4 mm rubber granules or powder, as required by production. During this stage, an additional magnetic separator is installed to eliminate any remaining fine steel wire, ensuring high rubber purity and stable product quality suitable for fuel, rubber products, or high-end surfacing applications.

In the final stages, the material passes through vibrating screening and a fiber separation system, where nylon fibers and light impurities are efficiently removed. As a result, the production line ultimately outputs three reusable resources: high-purity rubber powder or granules, recycled steel wire, and separated nylon fiber. With sealed conveying, multi-stage separation, and centralized dust removal, the entire system achieves clean, automated, and pollution-free tire recycling with minimal manual intervention. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Hydraulic Scrap Metal Baler for Industrial Recycling

- Mobile Two-Shaft Shredder Drives Flexible Recycling Operation

- Solar PV Panel Recycling Machine for End-of-Life Module Recovery

- Copper Wire Recycling Equipment for Fine and Mixed Cable Scrap

- Detailed Explanation of the Decoating Line for UBC and Aluminum Profiles

- Lithium-ion Battery Black Mass Recovery and Market Value

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export