How Cable Granulators Separate Copper from PVC

Copper Cable Granulator Systems work by first shredding cables into uniform pieces. A magnetic separator removes ferrous contaminants, and a granulator then crushes the material to separate copper conductors from the plastic insulation. After granulation, air separators use density differences to separate light plastic from heavy copper granules. Linear vibrating screens classify particles by size for optimal separation. Electrostatic separators can be added to achieve higher copper purity, resulting in clean copper granules and plastic.

Throughout the crushing and separation process, pulse-jet dust collection systems are installed to capture airborne dust and maintain a clean working environment. This design allows the entire line to comply with stringent environmental and occupational safety standards in the United States, the European Union, and other international markets. The final copper product, commonly referred to as “copper rice,” is bright, clean, and ready for direct sale to smelters or copper product manufacturers, while the separated plastic is suitable for secondary recycling.

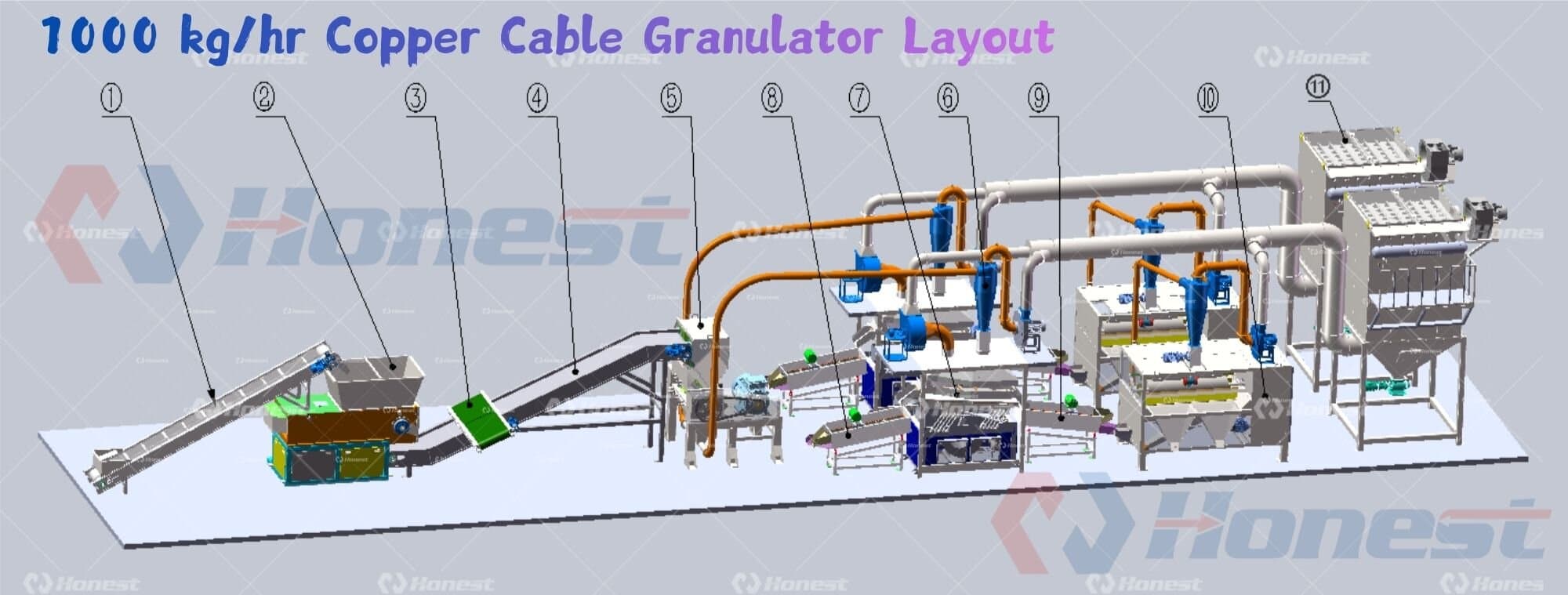

1000 kg/hr Copper Cable Granulator

From Scrap Wire to Pure Copper and PVC Pellets —– Process Flow Description (Corresponding to Equipment No. ①– ⑪) ① Feeding Conveyor ② Single-Shaft Shredder ③ Belt Magnetic Separator ④ Discharge Conveyor ⑤ Knife-Type Crusher Granulator ⑥ Air Conveying System (×2) ⑦ Air Separator (×2) ⑧ Linear Vibrating Screen – Copper Discharge (×2) ⑨ Linear Vibrating Screen – Plastic Discharge (×2) ⑩ Single-Roller Electrostatic Separator (×2) ⑪ Pulse-Jet Dust Collection System (×2)

We are a professional manufacturer of cable recycling machinery and equipment. Our professional technology and considerate service will provide you with the most reasonable personal solution. For more information about our machines, or to schedule a factory visit (in-person or virtual), please don’t hesitate to contact our sales team.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- How Cable Granulators Separate Copper from PVC

- Lithium-Ion Battery Recycling Line with Nitrogen Protection System

- A2 & FR ACP Aluminum Plastic Separation Recycling Machine

- Efficient Shredding Solutions for Waste Textiles and Used Clothing Recycling

- Solar Pv Panel Recycling System Pyrolysis-Based for Extracting Silicon

- How Should Different Types of Scrap Cables Be Recycled

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export