Copper Wire Recycling Machine With Air Separation

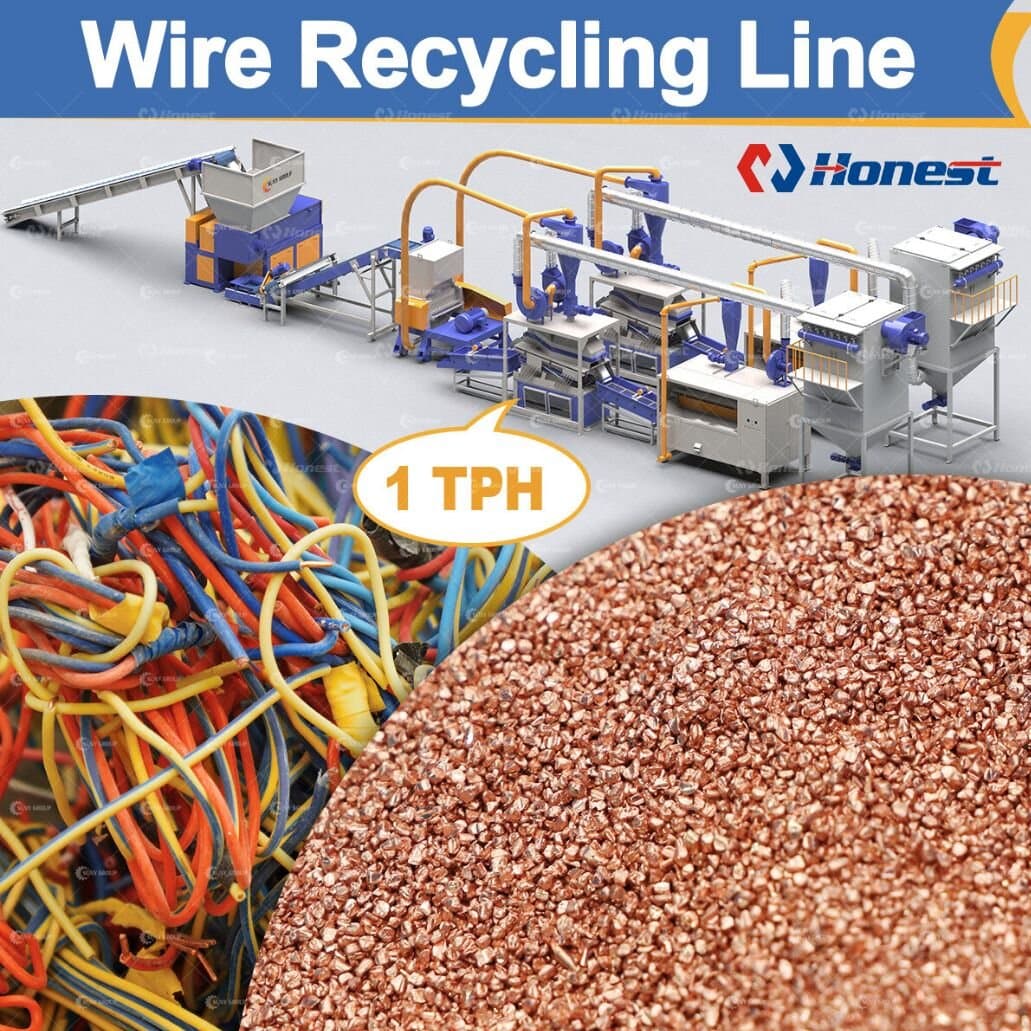

This copper wire recycling machine is designed for efficient processing of various waste electric cables, separating them into high-purity copper granules and clean PVC particles through advanced dry separation technology. It is suitable for wire diameters from 0.3 mm to 20 mm, including automobile wiring harnesses, motorcycle cables, communication wires, computer cables, and mixed scrap wires that are difficult to process with traditional stripping machines. Widely sourced from recycling stations, dismantling plants, power companies, and cable factories, these materials can be recycled with high efficiency and in compliance with environmental standards.

The core performance advantage lies in the negative-pressure pneumatic conveying system, which continuously draws cooling air through the crusher during operation. This design effectively controls temperature, prevents blade adhesion, and ensures stable processing of complex and tangled wires without frequent shutdowns. Compared with belt conveying systems, pneumatic conveying reduces mechanical wear, lowers maintenance frequency, improves equipment lifespan, and integrates cyclone cooling and dust removal to enhance overall recovery efficiency.

1000kg/hr Dry Type Copper Wire Recycling Machine

1000kg/hr Dry Type Copper Wire Recycling Machine

The complete recycling line is fully enclosed and environmentally friendly, eliminating dust leakage and secondary pollution while reducing operating costs. The standard configuration includes feeding and conveying systems, shredding (single-shaft shredder) and crushing (knife crusher) units, magnetic separation, pneumatic conveying, air separation, linear vibrating screening, electrostatic separation, and pulse dust collection. A linear vibrating screen is installed at the copper discharge outlet as the final stage for precision sorting. Its function is not merely basic separation, but rather accurate classification of bright copper, red copper, and brass flakes, which directly improves copper purity and market value. When the crusher screen size or material composition varies, the linear screen ensures stable quality control and prevents copper grade loss. Properly designed air separation already achieves high purity, while the vibrating screen serves as a refinement step rather than a compensation for poor separation performance.

The 1000kg/hr production line layout can be flexibly adjusted according to customer site conditions, delivering a reliable, high-value solution focused on long-term efficiency rather than low initial cost. For more machine information, or to schedule a factory visit (in-person or virtual), feel free to contact our sales team.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- Hydraulic Scrap Metal Baler for Industrial Recycling

- Mobile Two-Shaft Shredder Drives Flexible Recycling Operation

- Solar PV Panel Recycling Machine for End-of-Life Module Recovery

- Copper Wire Recycling Equipment for Fine and Mixed Cable Scrap

- Detailed Explanation of the Decoating Line for UBC and Aluminum Profiles

- Lithium-ion Battery Black Mass Recovery and Market Value

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

Over 20 years manufacturing and 14 years export