Workflow of Printed Circuit Board (PCB) Recycling Line

As intergovernmental organizations such as the United Nations (UN) and the World Economic Forum (WEF) increasingly focus on recycling unrecorded and unprocessed e-waste, this creates a huge opportunity for e-waste recyclers and smelters as well as e-waste, and Invest more in R&D and updating of recycling equipment. As a R&D manufacturer of recycling equipment, we have launched an e-waste recycling line – circuit board (PCB) recycling line.

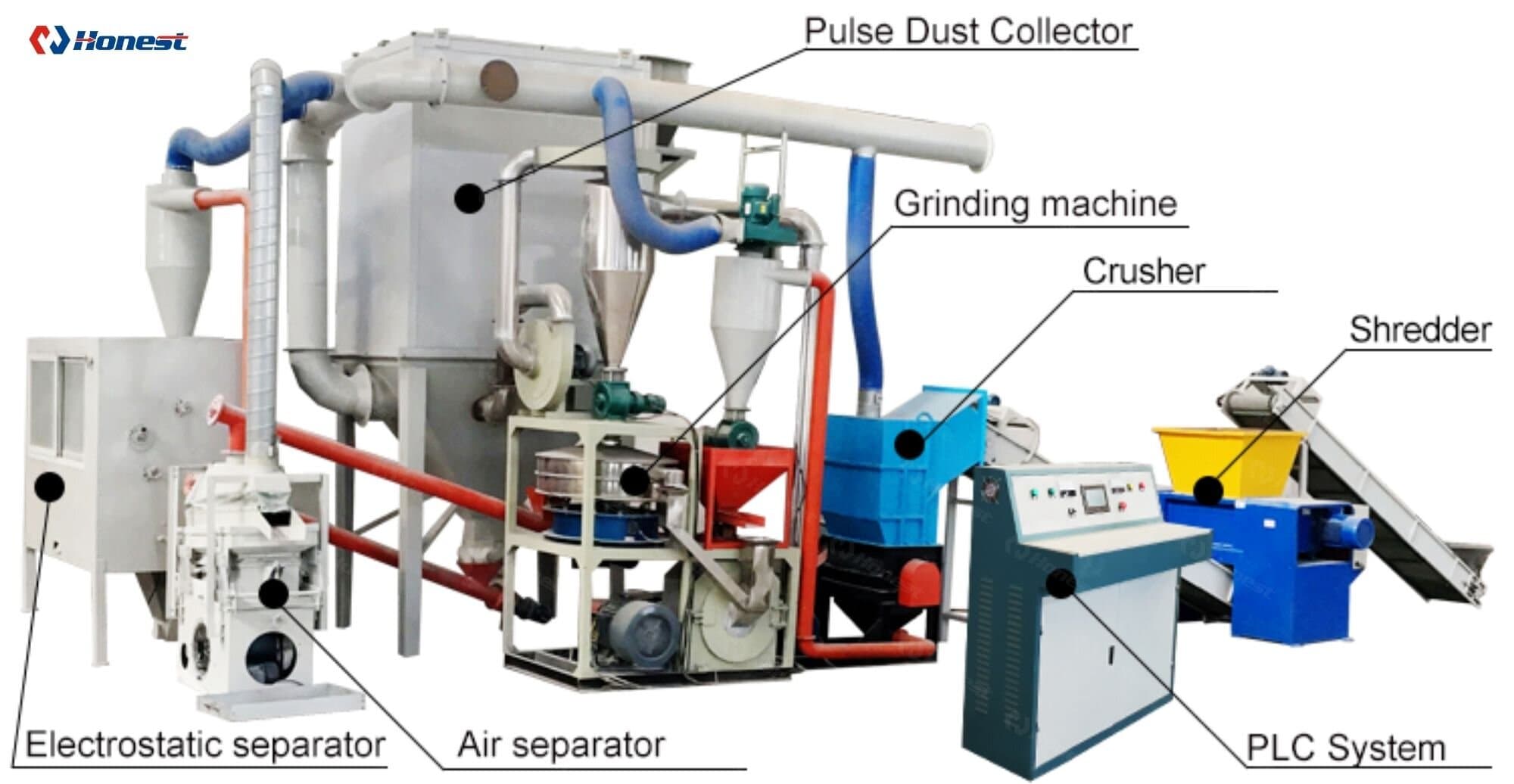

Our company’s printed circuit board (PCB) recycling line is mainly used for the separation of metal and non-metal in waste circuit boards, copper clad laminates, circuit boards, and scraps, as well as the recycling of copper powder and resin powder.

The main recycling process: divided into two parts, one is crushing materials, and the other is sorting materials. In the crushing stage, the first step of crushing can be equipped with a double-shaft shredder to initially process large pieces of material, which is convenient for subsequent equipment to further crush the material; the second step of crushing can be equipped with a hammer crusher to perform secondary crushing on the primary crushed material to achieve Fine selection of metal and non-metal powders;

waste wire recycling Line

waste wire recycling Line

If very few materials (PCB) cannot meet the separation requirements after two-step crushing, a high-speed eddy current crusher can also be equipped to improve production efficiency and output. In the separation stage, it is mainly equipped with airflow separation equipment, electrostatic separation equipment and magnetic separation equipment.

On the basis of scientific and reasonable matching, the recovery rate of copper can be improved and the production capacity can be increased. In addition, this production line is also equipped with the latest model of pulse dust removal equipment, which can minimize the emission of smoke and harmful gases. In line with international standards, it is more environmentally friendly on the basis of safe production. The whole production line is controlled by PCL, the production automation is controllable, the feeding is uniform, and the operation is coordinated. Bridges and guardrails are set up at the height of the entire production line, which is convenient for maintenance personnel to monitor and maintain the equipment in real time.

To sum up, the configuration of this production line is reserved by one of our customers in the United States. We will adjust some configurations according to the needs of customers and the actual situation. If you want to know more about printed circuit board (PCB) recycling lines, please contact us.

Contact Tel: +86 199 0388 6476

Contact Email: hnhonest.zack@gmail.com

Related News

- Complete Waste Refrigerator Dismantling and Recycling Line

- What Matters When Buying PCB Recycling Line

- EV Power Li-Ion Battery Recycling Line Test Run

- Retired Solar PV Panel Recycling Solution for Industry Use

- Mini Copper Granule Machines for Scrap Metal Yards

- ACP Sheet Separator for Aluminum Plastic Recycling

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience