Newly Upgraded Aluminum Composite Panel (ACP) Recycling Machine

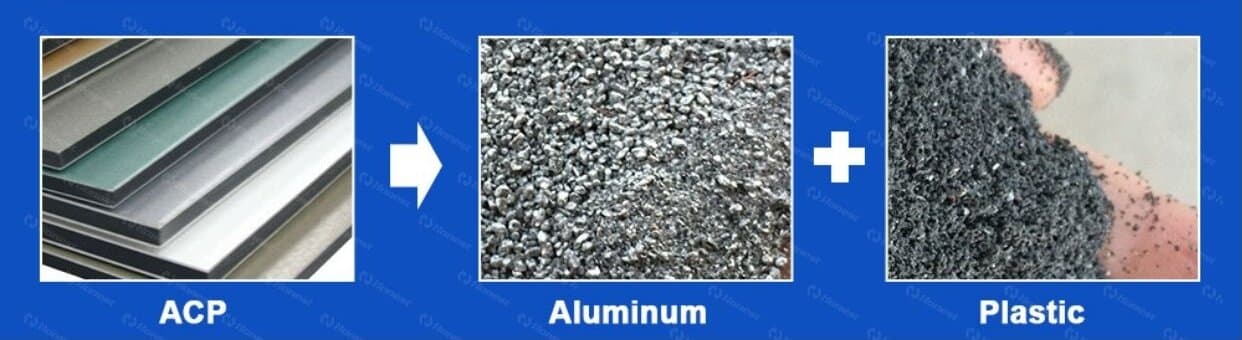

The Aluminum Composite Panel (ACP) Recycling Machine is designed to efficiently separate and recover aluminum and plastic from aluminum-plastic composite materials. This advanced system integrates shredding, crushing, vortex grinding, electrostatic separation, and dust removal technologies, achieving high-purity separation of aluminum powder and plastic particles.

The system newly upgraded is equipped with an intelligent PLC control panel and requires only 1–2 operators, making it a smart, labor-saving solution for aluminum plastic waste recycling.

Newly Upgraded Aluminum Composite Panel (ACP) Recycling Machine

Newly Upgraded Aluminum Composite Panel (ACP) Recycling Machine

This recycling production line is suitable for processing various types of plastic-aluminum composite waste and aluminum-based materials, including: Aluminum Composite Panels (ACP) and their fragments, waste plastic-aluminum packaging, toothpaste tubes, pharmaceutical blister packs and capsule plates, blister foil and aseptic foil seals, aluminum foil food bags and yogurt/milk bottle lids, bottleneck aluminum foil covers, circuit board aluminum laminates, PE/PVC/PVDC laminated materials, 8011 and anti-rust aluminum alloy foils, as well as aluminum composite tubes and sheets.

Want to learn how this machine can fit your recycling needs? Get in touch with our team today for tailored solutions, technical details, and competitive pricing.

👉 Contact Tel: +86 199 0388 6476

👉 Contact Email: hnhonest.zack@gmail.com

Related News

- What Matters When Buying PCB Recycling Line

- EV Power Li-Ion Battery Recycling Line Test Run

- Retired Solar PV Panel Recycling Solution for Industry Use

- Mini Copper Granule Machines for Scrap Metal Yards

- ACP Sheet Separator for Aluminum Plastic Recycling

- The Future and Value of Tire Recycling

Have this news-related demand?

We can help you!

Get in Touch

Connect with us anytime! Whether you have questions, need project assistance, or seek general help, our dedicated team is ready to assist. Fill out the form, and we'll promptly prioritize your satisfaction. We eagerly anticipate serving you.

If you have any requirement or suggestion, please fill in the form and send to us, thanks!

Email: hnhonest.zack@gmail.com

WhatsApp: +86 19903886476

HONEST - Experts in Waste Recycling Solutions

Equipment R&D Factory

Customers Worldwide

More Than 20 Years Of Export Experience